3D printing head feeding device

A feeding device and 3D printing technology, applied in coating devices, liquid material additive processing, processing and manufacturing, etc., can solve the problem of increasing the degree of sluggishness, affecting the efficiency of printing operations, the degree of feeding safety protection, aerodynamics and Hydraulic decline and other problems, to ensure the improvement of solidification, improve the effect of rack linkage operation, and improve the effect of refined processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

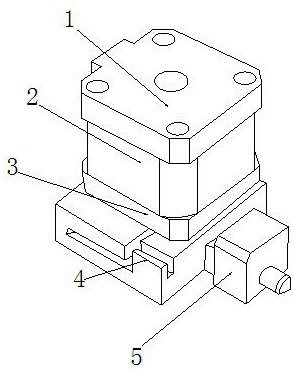

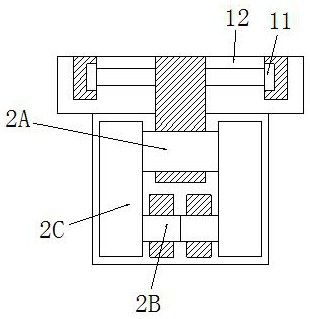

[0035] see Figure 1-Figure 8 , the present invention provides a 3D printing nozzle feeding device, its structure includes: end cover deck 1, roller rod double channel valve block 2, reverse buckle lining plate 3, guide shoe base plate 4, nozzle valve cap 5, the The roller rod double-channel valve block 2 is inserted under the bottom of the end cover deck 1 and is perpendicular to each other. Closely attached to the bottom surface of the reverse buckle liner 3 and on the same level, the nozzle valve cap 5 is inserted on the right side of the guide shoe base plate 4 and on the same level, the roller rod double channel valve block 2 A funnel column conduit 2A, a short ball valve tube 2B, and a gear sleeve roller rod 2C are provided. Two short ball valve tubes 2B are respectively inserted in the left and right lower corners of the funnel column conduit 2A. The roller rods 2C are mechanically connected and parallel to each other. The funnel column conduit 2A and the gear sleeve r...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a 3D printing nozzle feeding device, other aspects are the same as embodiment 1, the difference is:

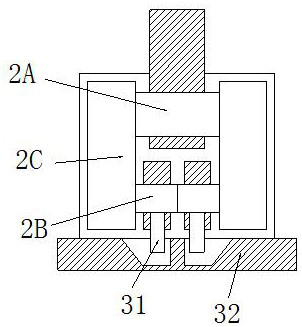

[0044] see image 3 , the reverse buckle lining 3 is composed of a reverse buckle rod 31 and a horizontal lining 32. The reverse buckle rod 31 is installed inside the horizontal lining 32. Together and perpendicular to each other, the effect of pulling and installing the shell is formed on the top of the horizontal liner 32 through the buckle bar 31 .

[0045] see Figure 6 , the anti-button bar 31 is made up of an alveolar pole 311 and a trapezoidal pinch plate 312. The alveolar pole 311 is installed on the top of the trapezoidal pinch plate 312. Inserted together and on the same vertical plane, the alveolar pole 311 is a composite pole structure with rack grooves on the left and right, which is convenient for the bolt to form a reverse buckle and draw and the shell plate connected by the top lock pin to closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com