Double-material packaging bottle capable of separately storing fluid materials

A fluid material and packaging bottle technology, applied in packaging, food packaging, household packaging, etc., can solve the problems of complicated operation and small amount of materials contained in the double-material dropper bottle, and achieve simple operation, convenient use, and user experience Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

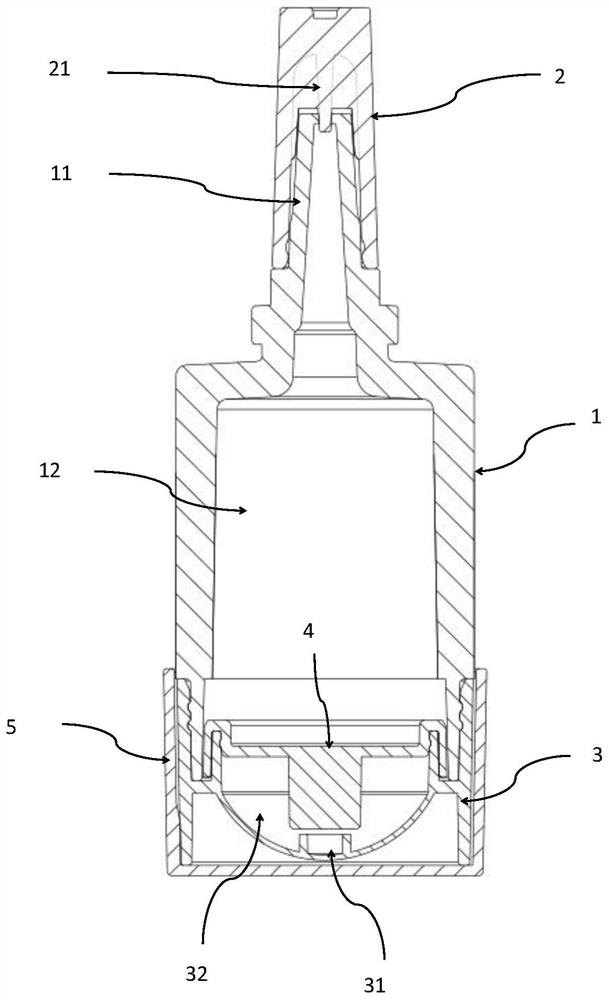

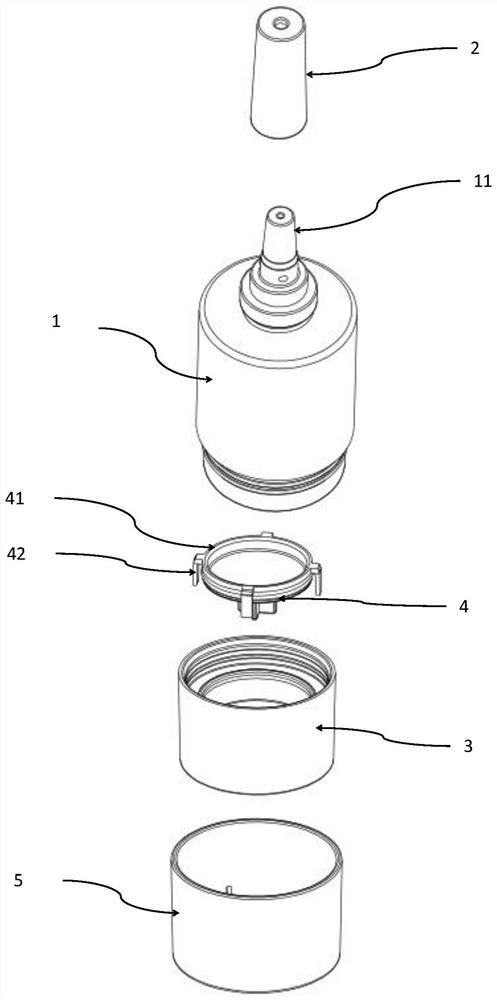

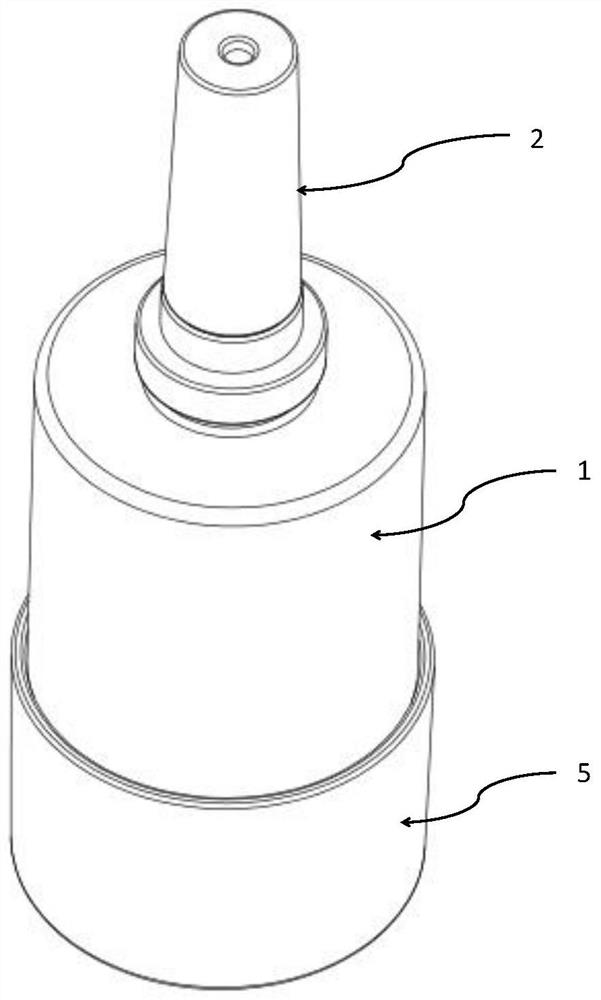

[0046] For a double-material packaging bottle for separately storing fluid materials provided by an embodiment of the present invention, please refer to figure 1 , figure 2 , image 3 and Figure 4 Shown, comprise: bottle body 1, outer cover 2 and the bottom of the bottle, bottle body 1 lower end is provided with bottle body lower opening, the top of bottle body 1 is bottle mouth 11, and in bottle body 1 is material body accommodating chamber 12, uses In order to accommodate the material body A, the lower opening of the bottle body communicates with the material body accommodating cavity 12, the bottle mouth 11 of the bottle body 1 is covered with an outer cover 2, the inside of the outer cover 2 is provided with a sealing plug 21, and the sealing plug 21 can be placed on the outer cover 2 When the cap is put on the bottle mouth 11, it is stuffed into the bottle mouth 11, and the sealing plug 21 is used to seal the bottle mouth 11 to prevent the material body A from leaking...

Embodiment 2

[0054] For a double-material packaging bottle for separately storing fluid materials provided by an embodiment of the present invention, please refer to Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, it includes: bottle body 1, outer cover 2 and bottom of the bottle, the bottom of the bottle includes base 3, inner plug assembly and bottom cover 5, bottle body 1, outer cover 2, base 3 and bottom cover 5 are all the same as the structure of embodiment 1 The difference is that the structure of the inner plug assembly is different. The inner plug assembly in this embodiment includes an inner plug 6 and a plug 7. The inner plug 6 is set on the top of the base 3, and a material accommodating cavity is formed between the base 3 and the inner plug 6. Two 32, used to accommodate the material body B, store the material body A and the material body B in a separate manner, the middle part of the inner plug 6 is provided with a material guide bin 61, and the material guide bin...

Embodiment 3

[0058] For a double-material packaging bottle for separately storing fluid materials provided by an embodiment of the present invention, please refer to Figure 9 , Figure 10 , Figure 11 and Figure 12 Shown, comprise: bottle body 1, outer cover 2 and the bottom of the bottle, the bottom of the bottle comprises base 8, inner plug assembly and bottom cover 5, the structure of bottle body 1, outer cover 2 and bottom cover 5 is all the same as embodiment 1, The difference between the base 8 and the embodiment 1 is that the structure of the annular boss 81 is different. The annular boss 81 of the present embodiment is circular, and there is no annular slot between the annular boss 81 and the inner wall of the base 8. The inner plug assembly includes an inner container 9 and a push rod 10. The cross section of the push rod 10 is C-shaped. The push rod 10 is vertically arranged between the base 8 and the inner container 9. The inner container 9 includes an inner container body 9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap