A kind of bolt grouting material for deep foundation pit construction and preparation method thereof

A technology for grouting materials and deep foundation pits, which is applied in the manufacture of rayon, textiles and paper, and conjugated synthetic polymer artificial filaments. It can solve the problems of low anchoring force, long coagulation time, and large water separation rate. Achieve the effects of favorable contact, good fluidity, and improvement of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

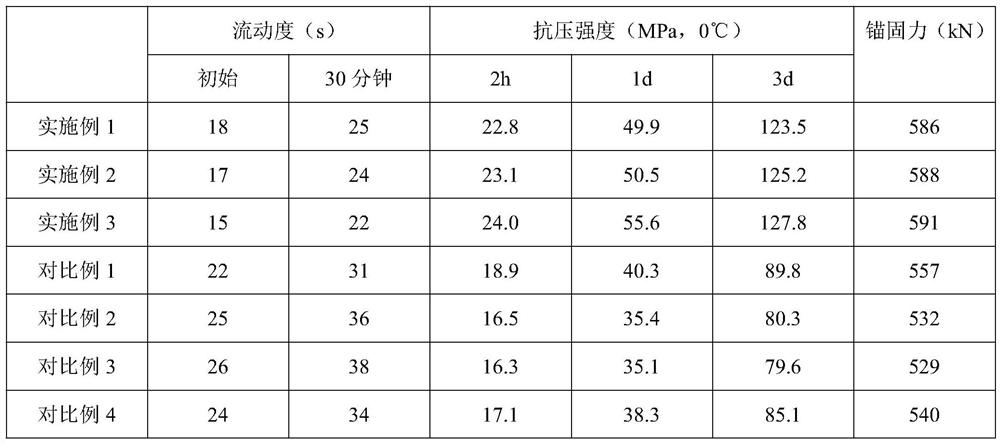

Examples

Embodiment 1

[0035] A method for preparing a bolt grouting material for deep foundation pit construction. First, 30kg of admixture, 2kg of admixture and 100kg of cement are mixed uniformly to obtain a solid material, and then 2kg of admixture is added to 65kg of water, stirred and mixed to obtain a solid material. Pre-mixed slurry, finally adding solid material into the pre-mixed slurry, stirring and mixing to obtain the bolt grouting material; wherein, the admixture is firstly the fly ash and corn stalk powder mixed with water and mixed with water. It is uniformly prepared into a slurry with a solid content of 20w.t.%, and then subjected to microwave treatment, solid-liquid separation, drying, calcination, and pulverization; the admixture is firstly made of aluminum silicate-calcium phosphate nanoparticles using N-( β-aminoethyl)-γ-aminopropyltriethoxysilane is modified to obtain modified nanoparticles, and then acrylamide and N-(4-aminophenyl)acrylamide are used as raw materials for polym...

Embodiment 2

[0054] A method for preparing a bolt grouting material for deep foundation pit construction. First, 40kg of admixture, 1kg of admixture and 100kg of cement are mixed uniformly to obtain a solid material, and then 3kg of admixture is added to 55kg of water, stirred and mixed to obtain a solid material. Pre-mixed slurry, finally adding solid material into the pre-mixed slurry, stirring and mixing to obtain the bolt grouting material; wherein, the admixture is firstly the fly ash and corn stalk powder mixed with water and mixed with water. It is uniformly prepared into a slurry with a solid content of 30w.t.%, and then subjected to microwave treatment, solid-liquid separation, drying, calcination, and pulverization. β-aminoethyl)-γ-aminopropyltriethoxysilane is modified to obtain modified nanoparticles, and then acrylamide and N-(4-aminophenyl)acrylamide are used as raw materials for polymerization reaction, In the polymerization process, aluminum silicate-calcium phosphate nanop...

Embodiment 3

[0073] A method for preparing bolt grouting material for deep foundation pit construction. First, 35kg of admixture, 1.5kg of admixture and 100kg of cement are mixed uniformly to obtain a solid material, and then 2.5kg of admixture is added to 60kg of water, and the mixture is mixed uniformly. , obtain the premixed slurry, and finally add the solid material into the premixed slurry, stir and mix to obtain the bolt grouting material; wherein, the admixture is to add water to fly ash and corn stalk powder first. Stir and mix to prepare a slurry with a solid content of 25w.t.%, and then undergo microwave treatment, solid-liquid separation, drying, calcination, and pulverization. -(β-aminoethyl)-γ-aminopropyltriethoxysilane is modified to obtain modified nanoparticles, which are then polymerized with acrylamide and N-(4-aminophenyl)acrylamide as raw materials In the reaction, aluminum silicate-calcium phosphate nanoparticles are added in the polymerization process, and the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com