Method for preparing xylooligosaccharide by combining lactic acid with xylanase hydrolysis

A technology of xylooligosaccharide and xylanase, which is applied in the field of biomass degradation and conversion, can solve the problems of low selectivity of xylooligosaccharide and insufficient hydrolysis of raw material xylan, so as to overcome many inhibitors and save The effect of high cost and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

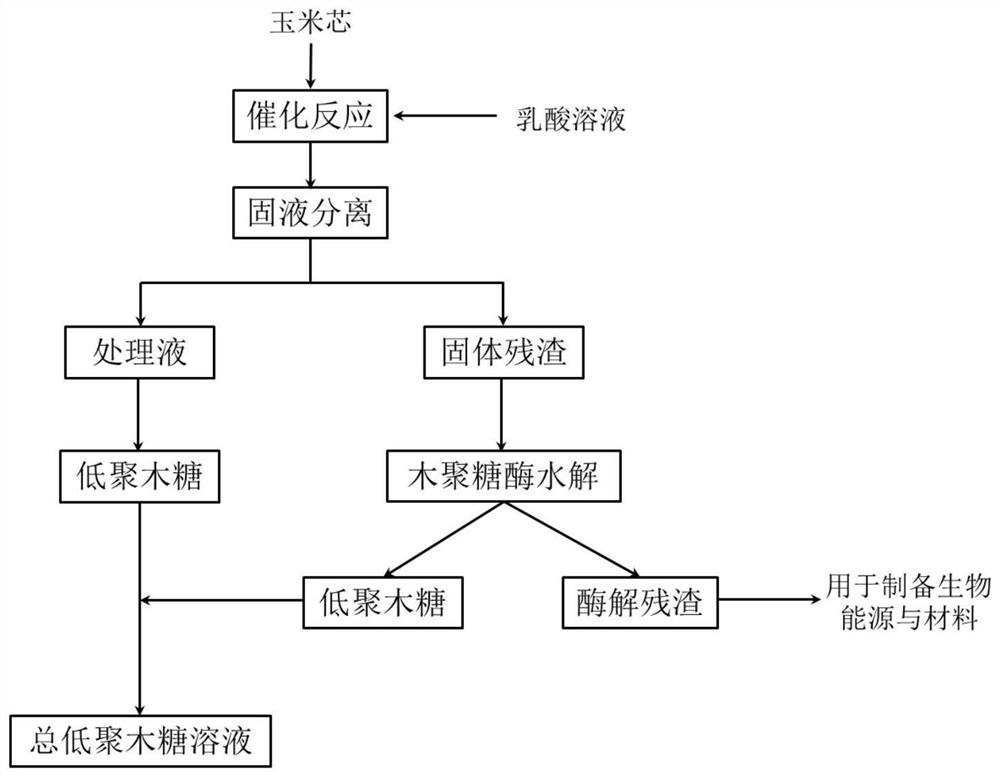

[0023] The invention provides a preparation method of xylooligosaccharides, comprising the following steps: mixing agricultural and forestry wastes with a lactic acid solution with a volume concentration of 0-10%, performing a catalytic reaction, and filtering to obtain a treatment liquid containing xylooligosaccharides and filter residue; mixing the filter residue with a xylanase solution for enzymolysis to obtain an enzymolysis solution containing xylooligosaccharides.

[0024] The present invention is not particularly limited to the type of agricultural and forestry wastes, and any agricultural and forestry wastes containing xylan-type hemicellulose known in the art can be used, preferably agricultural and forestry wastes containing a large amount of xylan-type hemicellulose, such as Corn stalks, wheat stalks, corn cobs, etc. In some embodiments of the present invention, corn cobs are selected. In the present invention, it is preferable to grind the agricultural and forestr...

Embodiment 1

[0032] Lactic acid catalysis: Accurately weigh corn cobs with an absolute dry weight of 1g, add a lactic acid solution with a volume concentration of 2% according to a solid-liquid ratio of 1g:10ml, heat at 160°C for 40min, cool, and perform solid-liquid separation. A treatment solution containing xylo-oligosaccharides is obtained; the filter residue is washed with deionized water until neutral to obtain a solid residue, which is then air-dried naturally.

[0033] Enzymatic hydrolysis of xylan: Take the filter residue with an absolute dry weight of 0.06g in a 10ml centrifuge tube, add 36U of xylanase, adjust the pH value to 4.8 with sodium citrate buffer, shake well and place it in a constant temperature shaker at 50°C After 24 hours of enzymolysis, boil in a boiling water bath for 10 minutes to inactivate the enzyme, cool to room temperature, centrifuge, and obtain an enzymolysis solution containing xylooligosaccharides from the supernatant.

[0034]Use high-performance liqui...

Embodiment 2

[0042] The difference from Example 1 is that the corncobs are not subjected to lactic acid catalytic treatment, but are directly subjected to xylan enzymatic hydrolysis, and the rest of the enzymatic hydrolysis conditions are the same as in Example 1.

[0043] As a result, the yields of xylobiose, xylotriose, xylotetraose, xylopentaose and xylohexaose in the enzymolysis solution were 11.1%, 1.2%, 1.6%, 0.4% and 0.2%, respectively. The yield of xylose was 14.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com