A treatment method for desert engineering foundation pre-soaked water dynamic compaction

A treatment method and pre-soaking technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems that cannot meet the desert foundation characteristics and affect the construction process, and achieve the reduction of the gap between sand grains, the increase of viscosity, and the promotion of pressure. The effect of the real process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

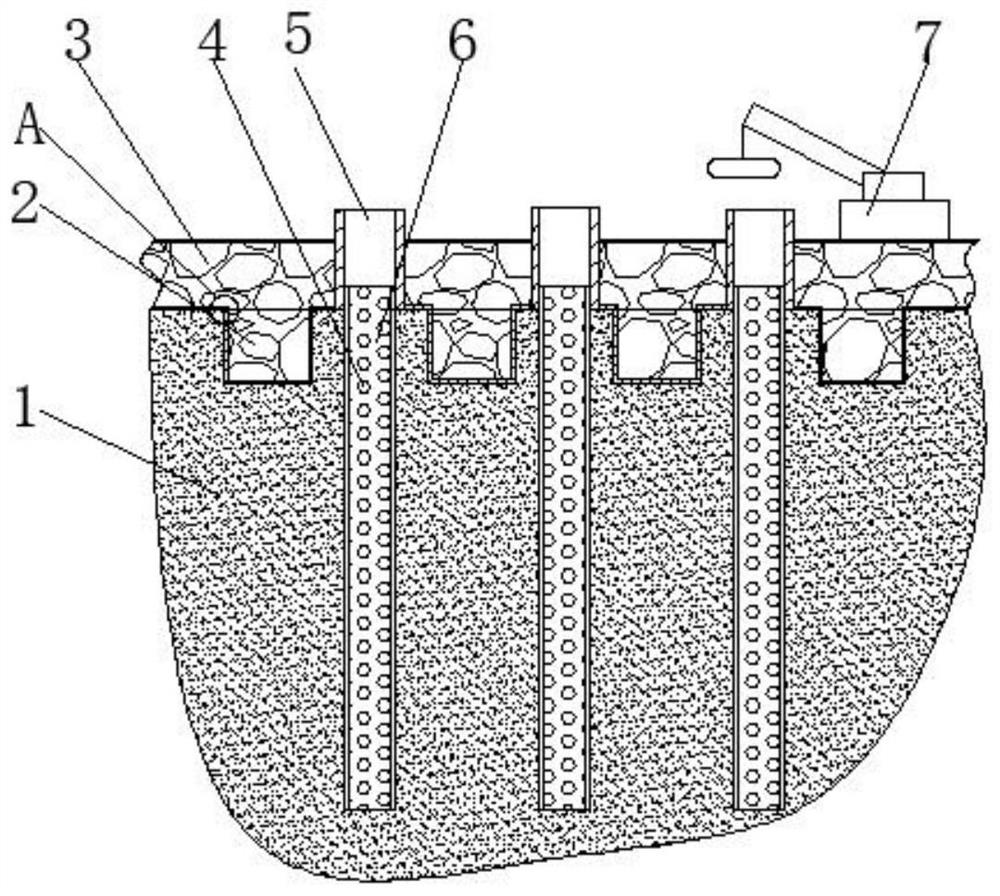

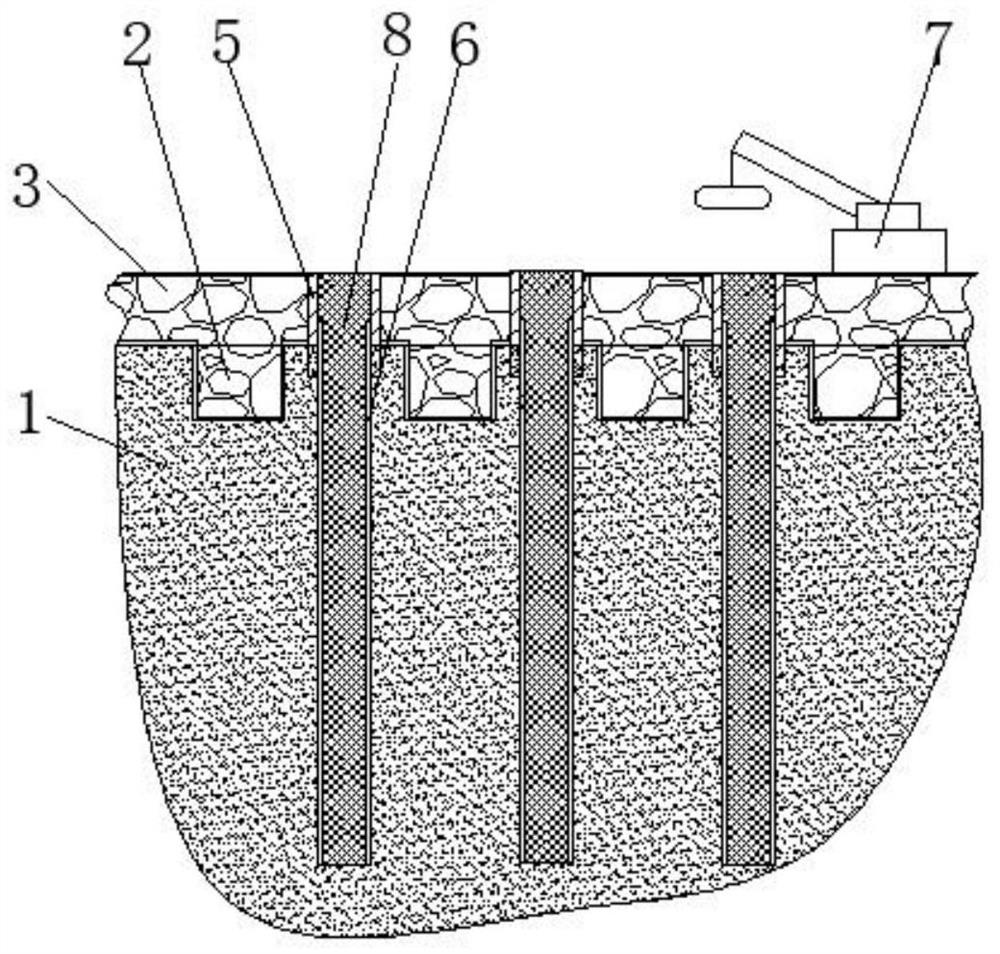

[0036] Such as Figure 1-3 As shown, the embodiment of the present invention provides a desert engineering foundation pre-soaked water dynamic compaction treatment method, comprising the following steps:

[0037] Step 1 Determine the scope of foundation construction

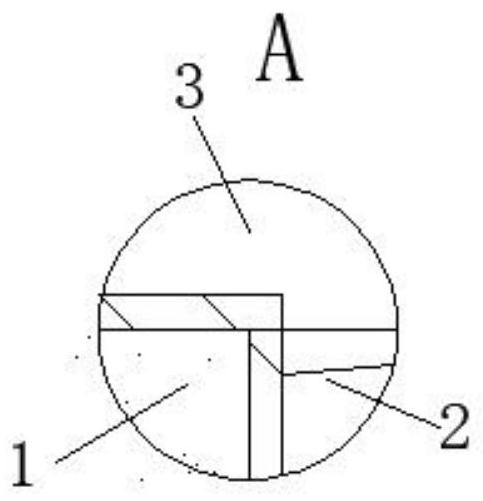

[0038] According to the pre-determined construction scope of the desert foundation 1, use steel pipes with a spacing of 2.5-3m and an embedded depth of 1-1.5m to surround the edge. After the laying of the cushion layer 3 is completed, the steel pipe will block the cushion layer 3, This can reduce the displacement of the cushion layer 3 during the rolling process, making the previously defined construction scope unclear, and then use excavators and bulldozers to backfill and level the construction scope of the desert foundation 1, and then use small-tonnage road rollers Carry out preliminary rolling within the construction range of the desert foundation 1, so that the desert foundation 1 is initially compacted, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com