Locking and fixing device facilitating submarine pipeline transportation

A technology for fixing devices and subsea pipelines, applied in the directions of pipes/pipe joints/fittings, sleeve/socket connections, through components, etc., can solve the problems of lack of availability, and achieve the effect of convenient transportation, rapid installation and disassembly, and convenient laying out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

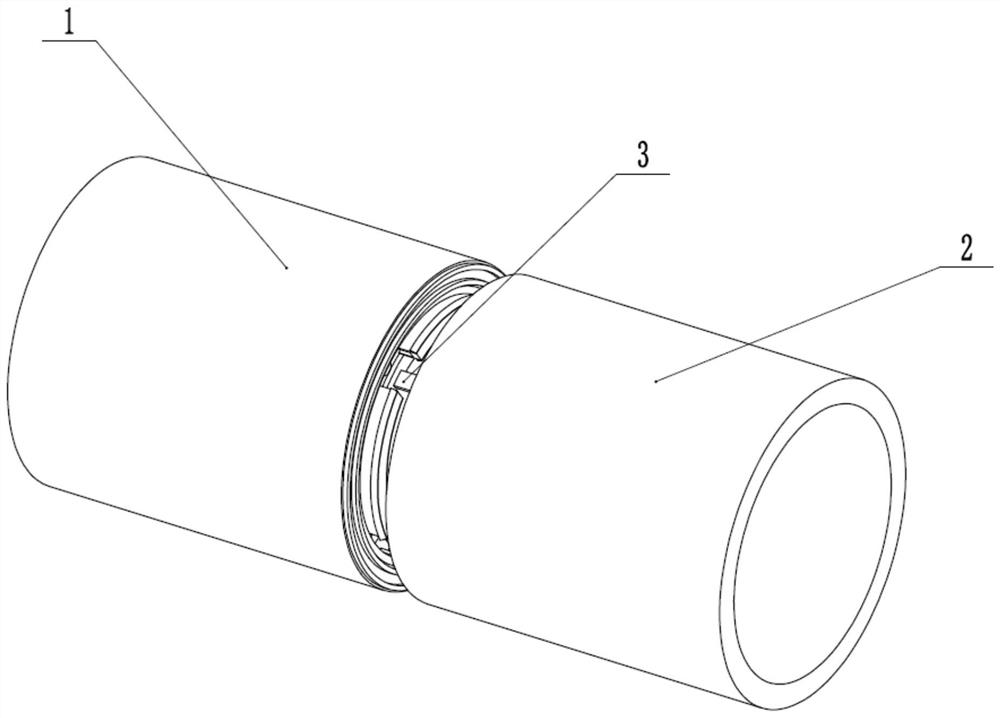

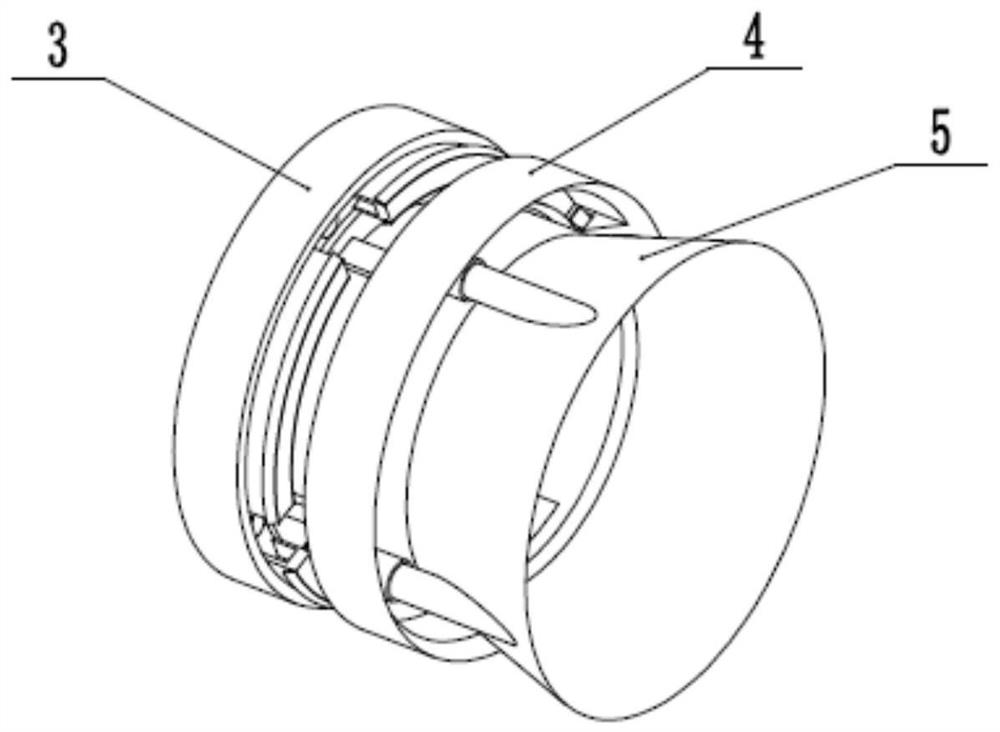

[0029] Such as Figure 1 to Figure 9 As shown, a locking and fixing device for submarine pipeline transportation is convenient, including an inner sealing pipe 1, an outer connecting pipe 2, an inner pipe fixing and connecting variable diameter seat 3, an outer pipe connecting variable diameter locking seat 4 and a variable diameter outer locking seat 5. The inner tube is fixedly connected to the variable diameter seat 3 and is fixedly connected to the outer end of the inner closed tube 1, the outer tube is connected to the variable diameter locking seat 4 and is fixedly connected to the inner end of the outer connecting tube 2, and the inner tube is fixedly connected to the variable diameter seat 3 and the outer tube connecting variable diameter locking seat 4 are in clearance fit with each other, and the variable diameter outer locking seat 5 is inserted into the outer tube connecting variable diameter locking seat 4, and the variable diameter outer locking seat 5 is fixedly ...

specific Embodiment approach 2

[0031] Such as Figure 1 to Figure 9 As shown, this embodiment further explains Embodiment 1. The outer wall of the inner closed pipe 1 is provided with a plurality of sealing grooves, and the inner wall of the outer connecting pipe 2 is provided with a plurality of sealing grooves. The inner sealing pipe 1 and the outer connecting pipe 2 are provided with a plurality of sealing rings. After locking the inner closed pipe 1 and the outer connecting pipe 2, multiple sealing rings are used to prevent leakage.

specific Embodiment approach 3

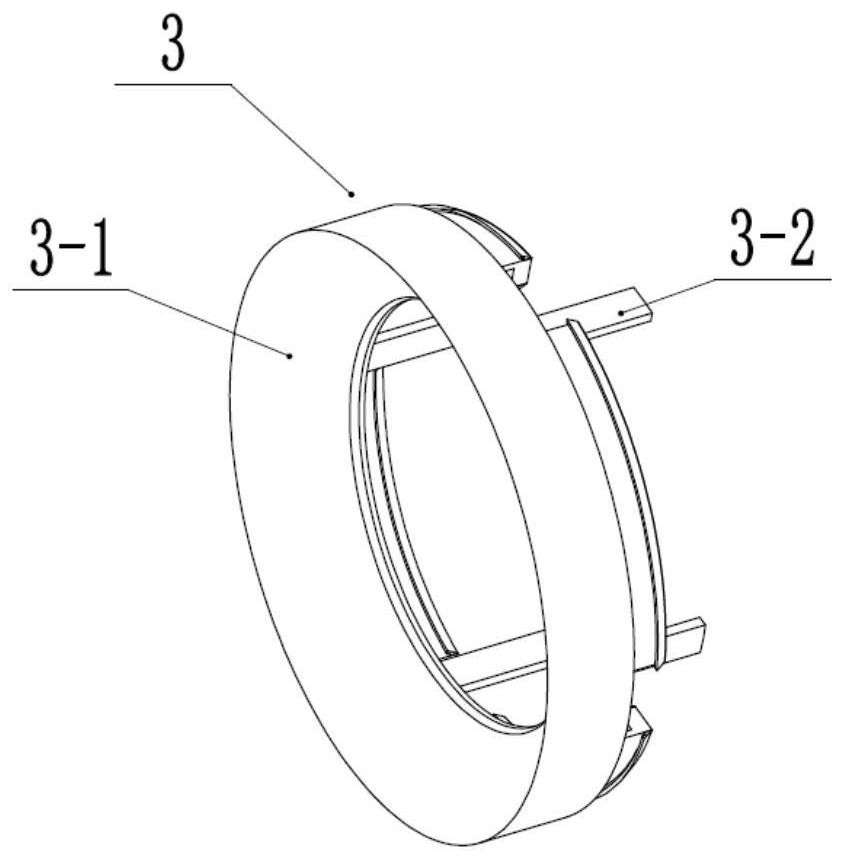

[0033] Such as Figure 1 to Figure 9 As shown, this embodiment will further explain the second embodiment. The inner tube fixedly connected with the variable diameter seat 3 includes the internal variable diameter seat 3-1, a plurality of clearance locking helical racks 3-2, and a locking ring Groove 3-3, multiple top-tight round hole grooves 3-4, multiple locking seats 3-5 and multiple locking slope grooves 3-6, the inner reducing seat 3-1 is fixedly connected to the inner wall of the inner closed tube 1 The outer end of the outer end, a plurality of gap locking helical racks 3-2 are uniformly fixedly connected to the rear end of the inner reducer 3-1, and the locking ring groove 3-3 is arranged at the rear end of the inner reducer 3-1 , a plurality of top tight round hole grooves 3-4 are evenly arranged in the locking ring groove 3-3, and a plurality of locking seats 3-5 are evenly fixedly connected in the locking ring groove 3-3, and the locking seat 3 The two ends of -5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com