A kind of antenna component, electronic equipment, the manufacturing method of antenna component

A technology for antenna components and manufacturing methods, which is applied to antenna components, antennas, antenna supports/mounting devices, etc., and can solve the problems of being easily oxidized, affecting the stability of the working performance of MDA antennas, and increasing the feed point resistance of MDA antennas and other issues, to achieve the effect of stable performance and light weight, good signal transmission and reception performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

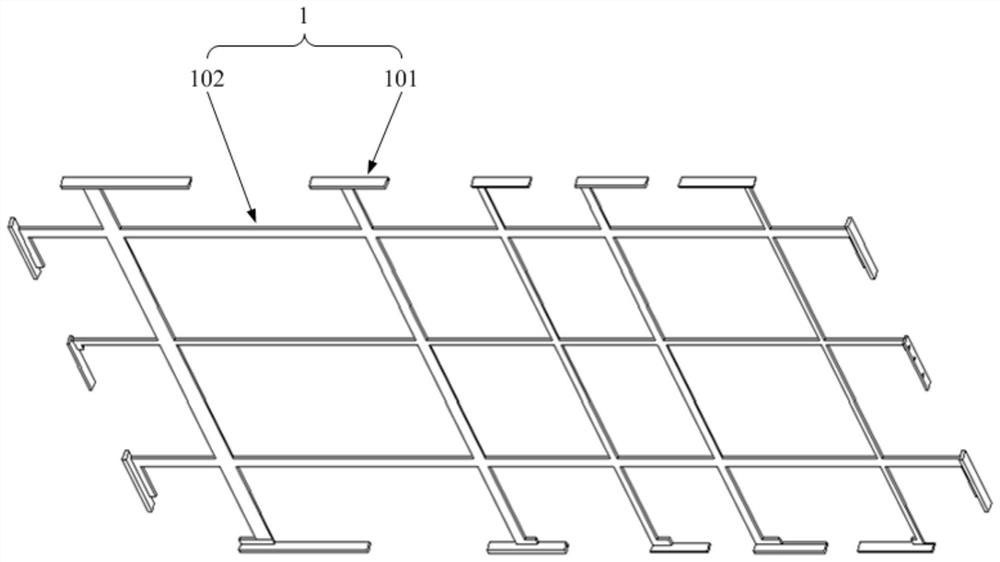

[0040] The application provides an antenna assembly, which can make the stability of its working performance obtainable under the condition of light weight.

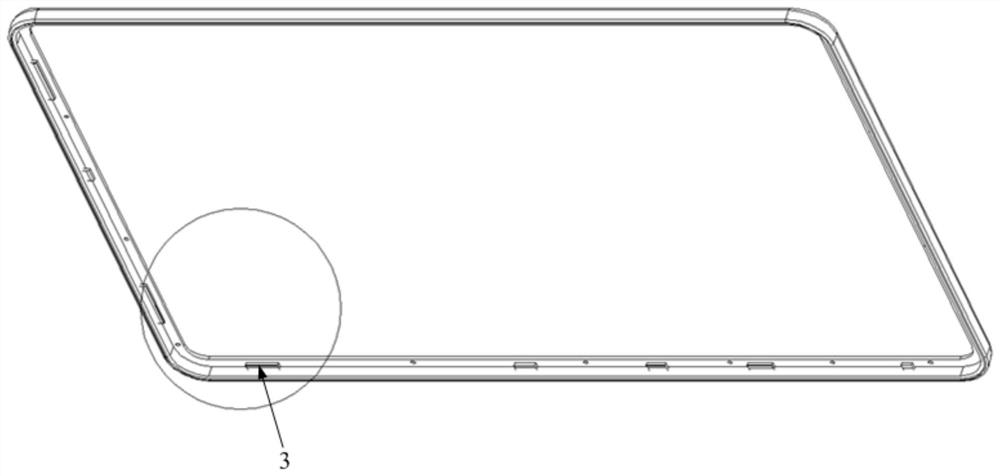

[0044] As shown in Figure 3 and Figure 4, it is also preferred that the functional part 101 is connected with a conductive member exposed to the outside of the carrier 2.

[0049] In addition, the present application also provides a method for manufacturing an antenna assembly, which is used to manufacture the aforementioned antenna assembly.

[0050] The first material is processed to obtain the antenna base, the metal activity of this first material being weaker than that of the reference material

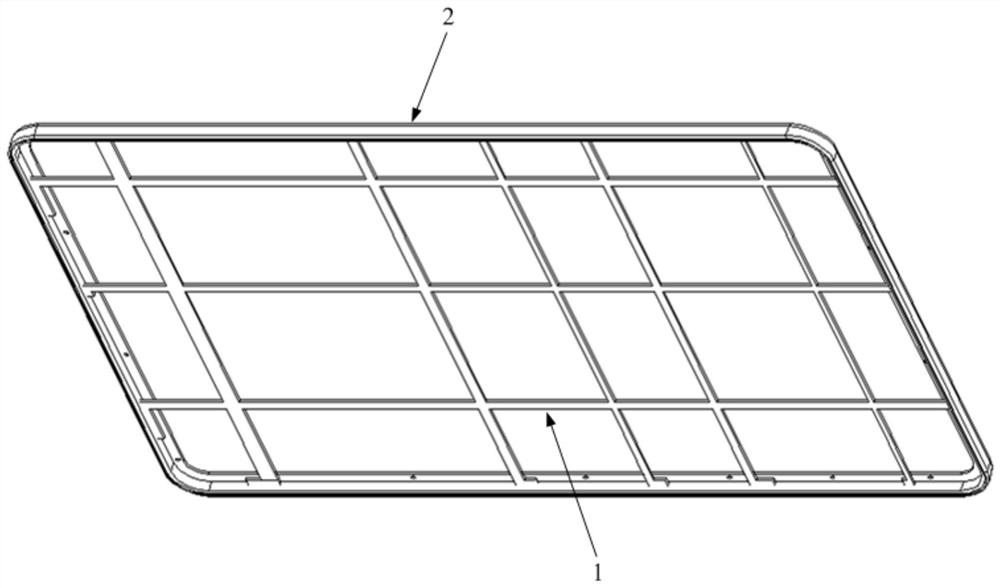

[0051] The carrier 2 is injection-molded, and the carrier 2 is injection-molded with the plurality of functional parts 101 of the antenna base to form

[0058] In the above-mentioned manufacturing method, the injection-molded connector and the mounting member 4 are preferably bonded or connected using a connector. Injection con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com