A distribution unit for milk samples comprising two separate parts

A technology of distributing unit and analyzing unit, which is applied in applications, dairy products, milking devices, etc., and can solve problems such as time-consuming and busy analyzing unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

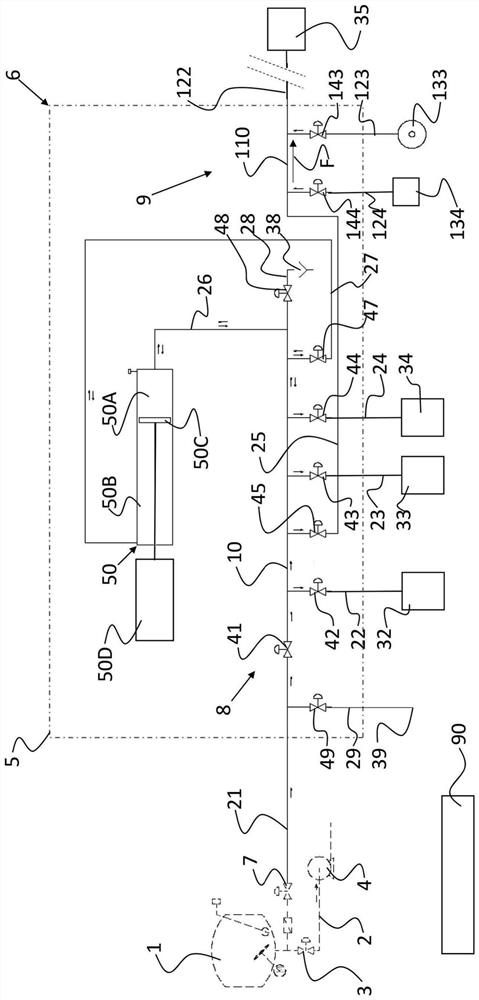

[0035] figure 1 A milk receptacle 1 is disclosed which collects milk from an animal being milked by a milking machine. The milk receiver 1 may be located at or in a local position in a milking station where the animal is milked, eg an automated robotic milking station.

[0036] The milk line 2 is connected to the bottom of the milk receiver 1 . The milk line 2 comprises a valve 3 and a milk pump 4 . When the valve 3 is in the open position and the milk pump 4 is activated, milk is pumped from the milk receiver 1 via the milk line 2 to a milk tank (not disclosed), which may be arranged to collect milk from a plurality of milk receivers 1 .

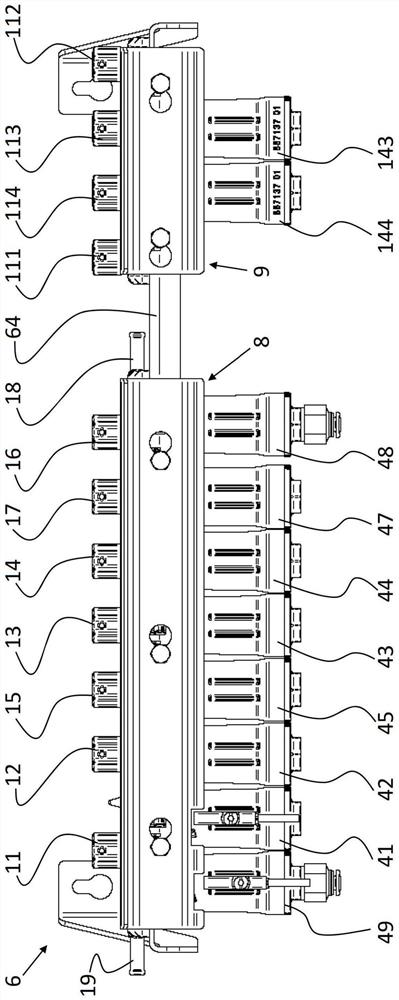

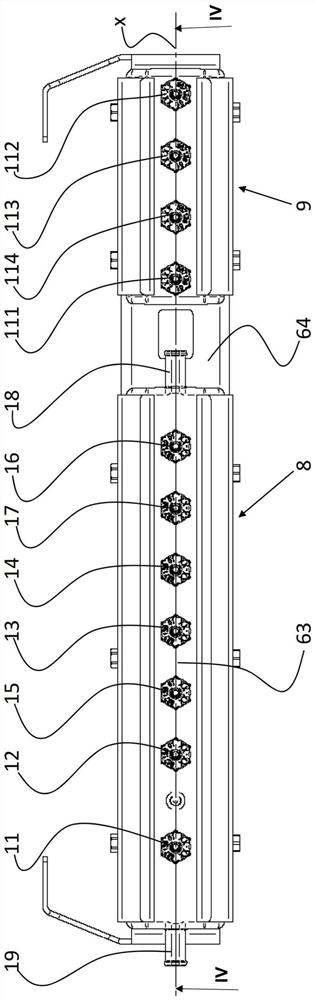

[0037] figure 1 Also disclosed is a milk sampling device 5 configured to receive a milk sample of milk from the milk receiver 1 prior to transferring the milk to a milk tank. The milk sampling device 5 comprises a dispensing unit 6, which in Figure 2-14 disclosed in more detail. A main valve 7 is provided for opening and closing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com