Heavy metal pollutant treatment equipment

A technology for pollutant treatment and heavy metal, applied in the field of heavy metal pollution, can solve the problems of cost and harvest not proportional, energy and time, contact neps and other problems, to reduce maintenance time and cost, strengthen the effect, increase the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

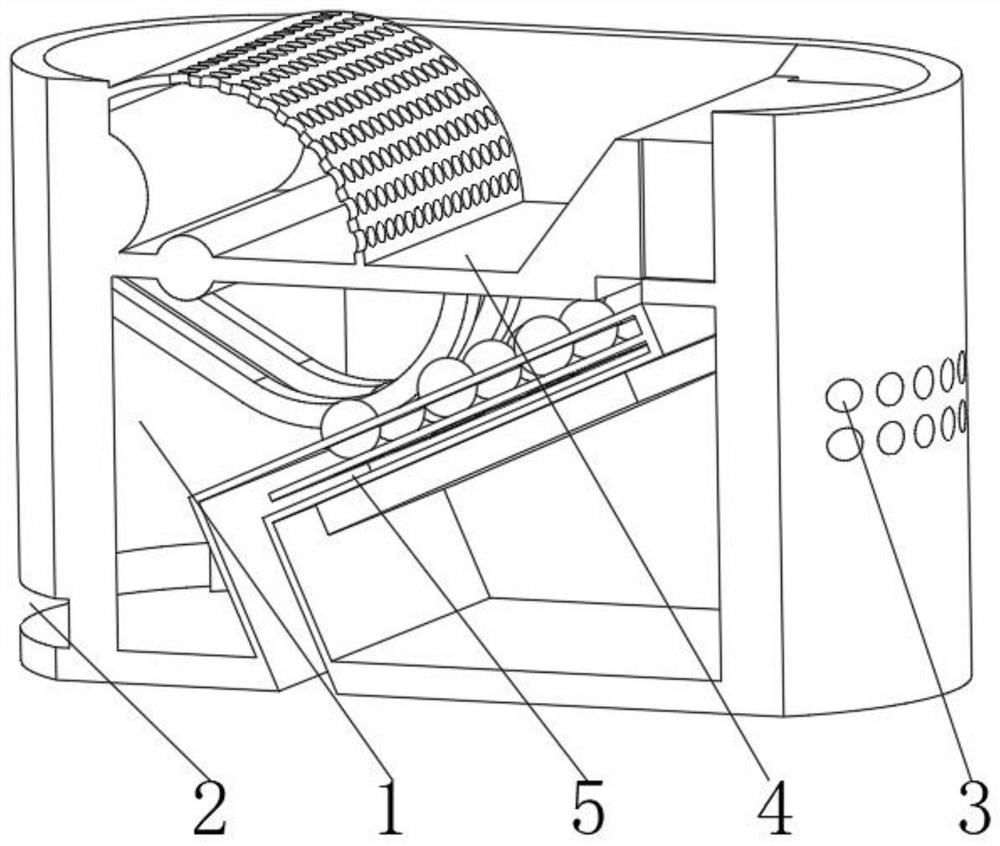

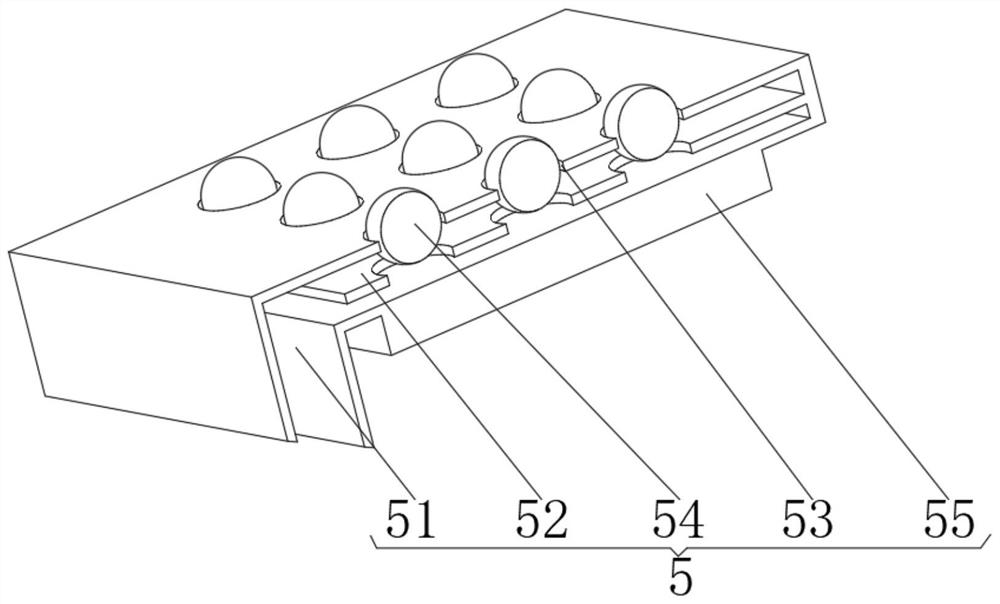

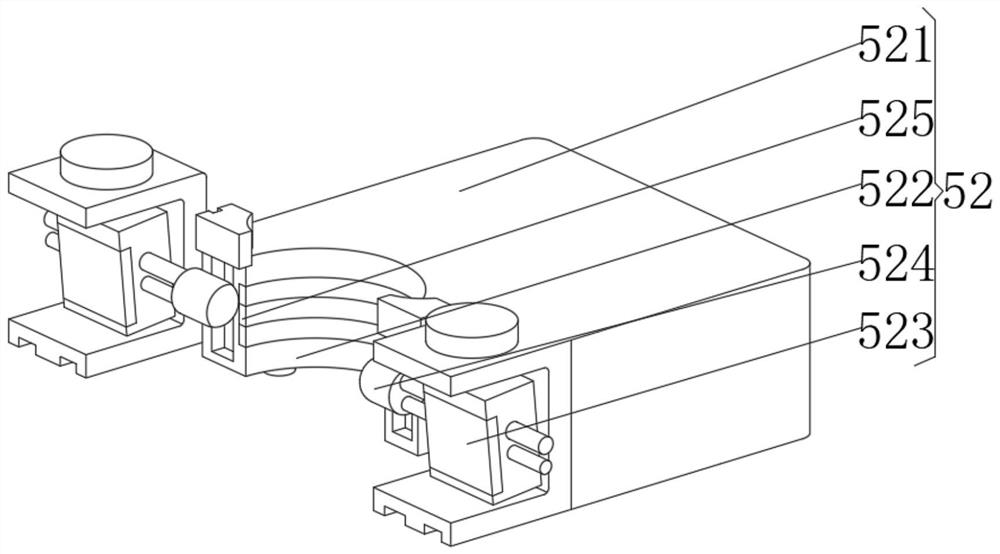

[0038] see Figure 1-3 , the present invention provides a technical solution: a heavy metal pollutant treatment equipment, specifically comprising:

[0039] Processing box 1, the processing box 1 has a loop-back box body, and an outlet 2 provided at the bottom of the left side outer wall of the loop-back box body, and a vent hole 3 provided at the middle position of the right side outer wall of the loop-back box body, and installed in the loop-back box body The primary filter device 4 on the top of the surface, and the reaction device 5 installed at the bottom of the primary filter device 4, balance the internal and external air pressure through the setting of the vent hole 3, so as to avoid the change of the internal and external air pressure caused by the reaction gas generated during the treatment process, which will affect the internal heavy metal pollution The processing process of the material ensures that the processing process is smooth and the reaction is more fully a...

Embodiment 2

[0049] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a kind of technical scheme: primary filter device 4 comprises:

[0050] End plate 41, this end plate 41 has semicircle plate body, and the positioning shaft 42 that is installed on the right side of semicircle plate body, and the winder 43 that is installed on the top of semicircle plate body, and the branch that is installed on winder 43 outer surfaces Screen plate 44, and the bearing plate 45 that is installed on the outer surface of the positioning shaft 42, and the flow hole 46 that is opened on the right side of the bearing plate 45, and the inclined plane infusion pump 47 that is installed on the top of the bearing plate 45 and is located above the flow hole 46, and The bent rod device 48 installed on the bottom of the end plate 41 . The design of the inclined plane infusion pump 47 can preliminarily precipitate the heavy metal pollutants, avoiding the blockage of the equipment by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com