Screening mechanism

A technology for extracting fans and driving motors, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of manual screening, low work efficiency, etc. The effect of high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

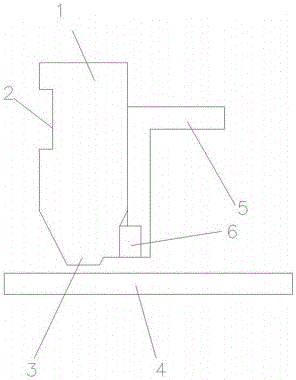

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

[0010] As shown in Figure 1, a kind of screening mechanism comprises feed hopper 1, and described feed hopper 1 comprises feed inlet 2 and discharge outlet 3, and the below of described feed hopper 1 is provided with conveyer belt 4, and described The lower part of the feed hopper 1 is provided with an exhaust fan 6 and a feeding pipe 5 , the exhaust fan 6 is arranged above the discharge port 3 and communicates with the feed hopper 1 , and the feed pipe 5 communicates with the exhaust fan 6 .

[0011] The material enters the feed hopper 1 through the feed port 2, and the exhaust fan 6 starts to work to suck out the light impurities in the material and send them out through the feed pipe 5, and the screened materials pass through the discharge port 3 and fall into the conveying Belt 4 does not affect the original work flow, the transformation cost is low, the screening effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com