Precision seeding device for beans

A technology of precision seeding and beans, applied in the direction of single-seed seeder, sowing seeder, planter parts, etc., can solve the problems of not being able to achieve precise single-grain on-demand seeding, limiting the working efficiency of precision seeders, and high pressure on seeds, etc. It achieves the effects of good maintenance, good seeding effect and high seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

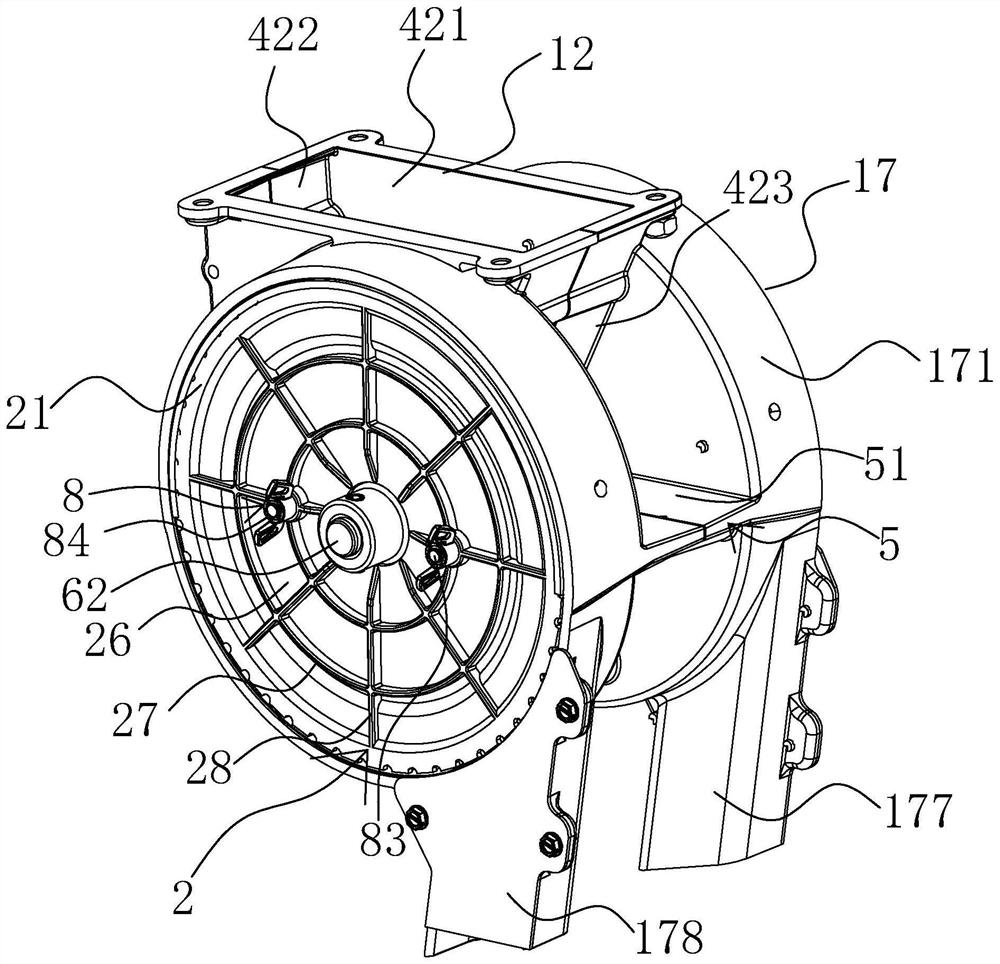

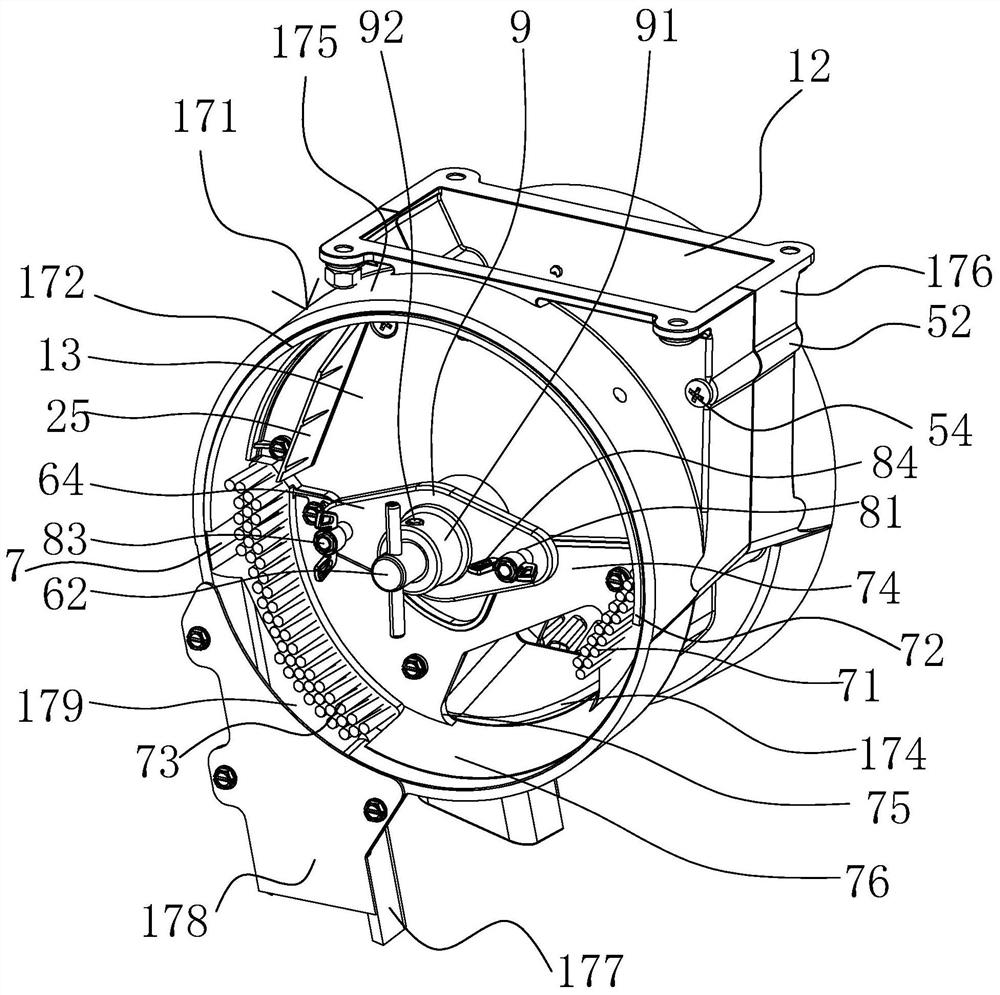

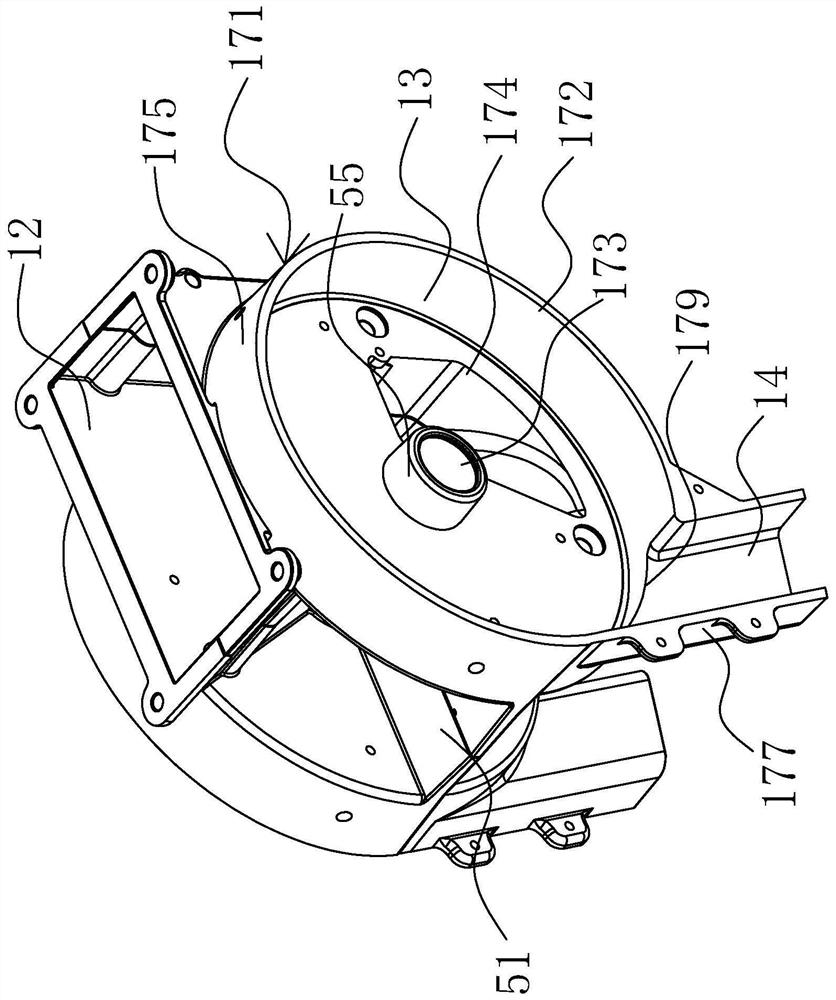

[0034] like Figure 1-11 As shown, the bean precision sowing device includes a sower main body 1 installed on the sowing single group 11, a seed inlet 12 is provided at the upper end of the sower main body 1, and the two sides of the sower main body 1 are respectively rotated to be provided with sowers arranged correspondingly. The disc assembly 2 has two sowing bins 13 located inside the sowing disc assembly 2 and connected to the seed inlet 12 in the seeder main body 1, and two sowing bins 13 are respectively connected to the seeding bins 13 at the lower end of the seeder main body 1 Tong's seed outlet 14. By setting the sowing bins 13 corresponding to the sowing disc assemblies 2 on both sides of the seeder main body 1, the bean seeds passing through the seed inlet 12 can enter the different sowing bins 13 on both sides, thereby r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com