Vegetable harvesting machine

A technology for harvesting machines and vegetables, which is applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inability to harvest vegetables in the soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

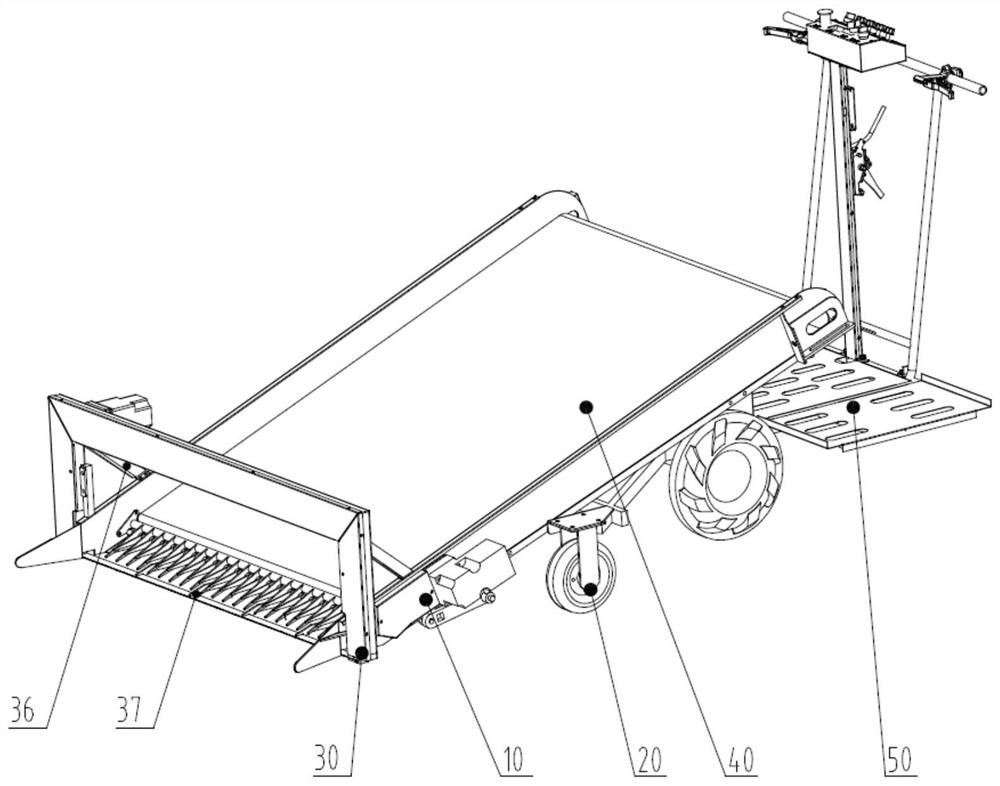

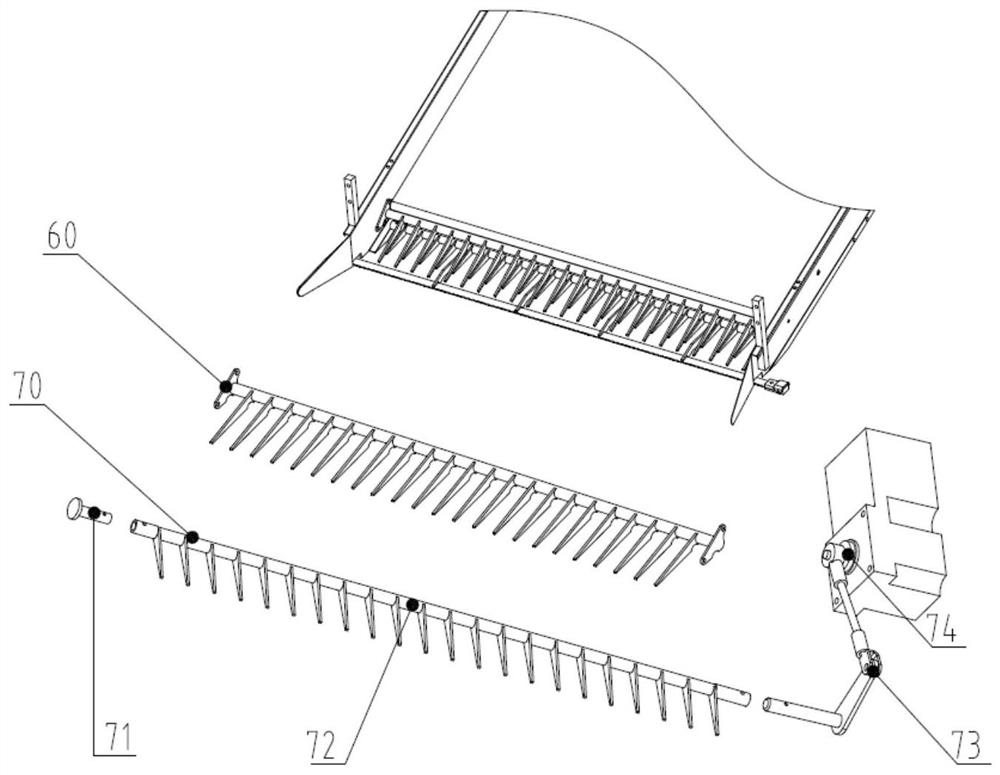

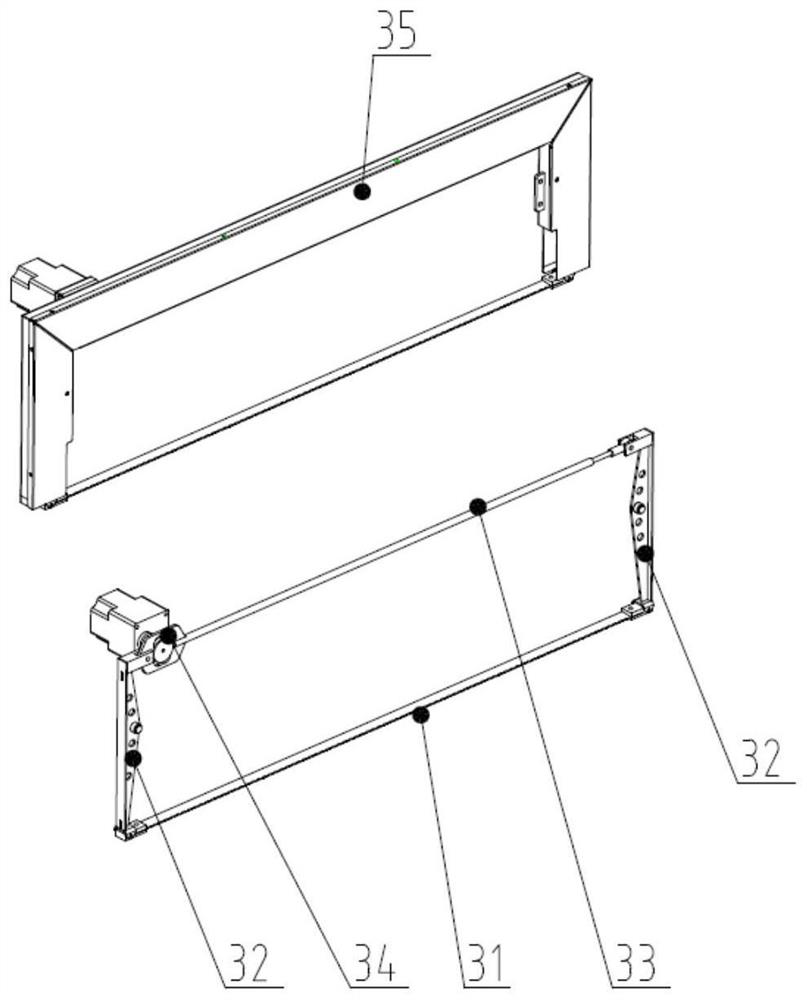

[0025] Such as Figure 1-3 As shown, the vegetable harvester is powered by a lithium iron phosphate battery, and the vegetable harvesting is realized by controlling the actions of various components through the motor. The bottom end of the chassis frame 10 is equipped with a walking mechanism 20, and the upper end is obliquely placed with a conveying device 40. The rear end of the conveying device 40 extends backward from the chassis with a collecting device 50; the front end of the conveying device 40 is fixed on the chassis frame. The guide device is composed of connecting rods and guide teeth evenly distributed on the top. The lower end of the guide device 60 is movably connected to the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com