Energy-saving and environmentally-friendly waste paper crushing and recycling device

An energy saving, environmental protection, recycling device technology, applied in presses, grain processing, manufacturing tools, etc., can solve the problems of low pulverization efficiency and uneven pulverization, and achieve the effect of improving pulverizing effect and pulverizing effect, pulverizing evenly, and saving electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

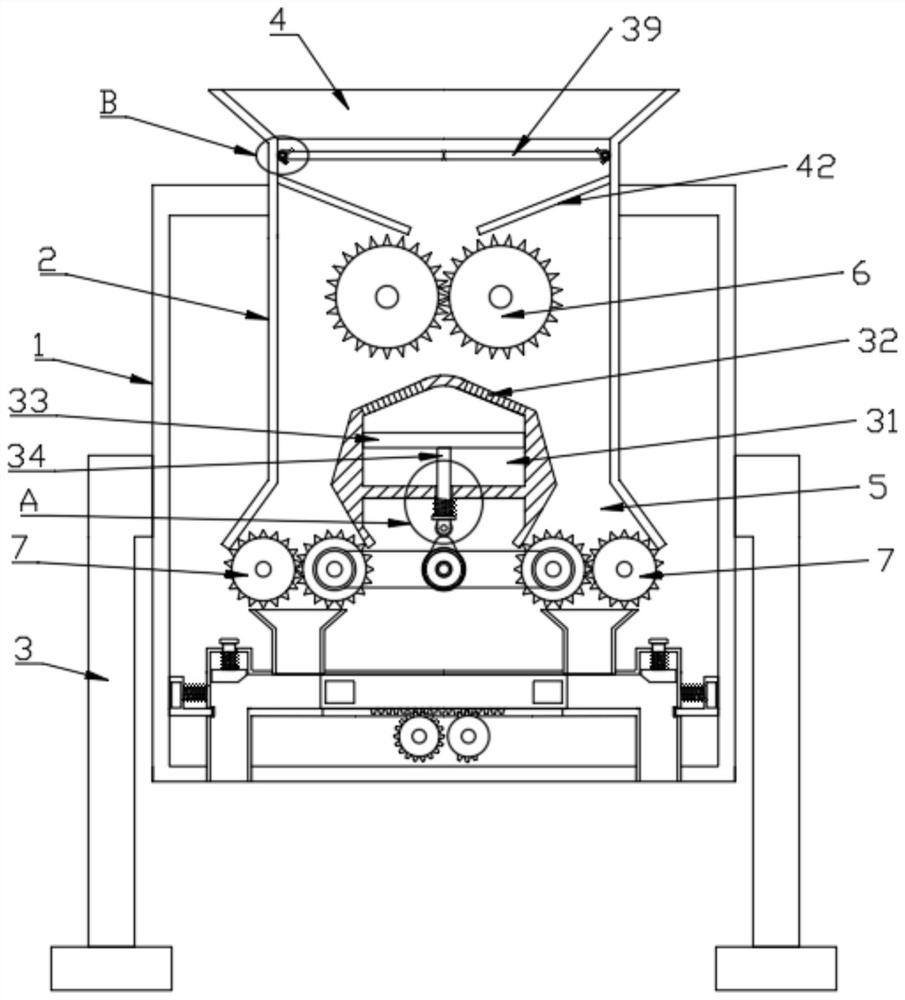

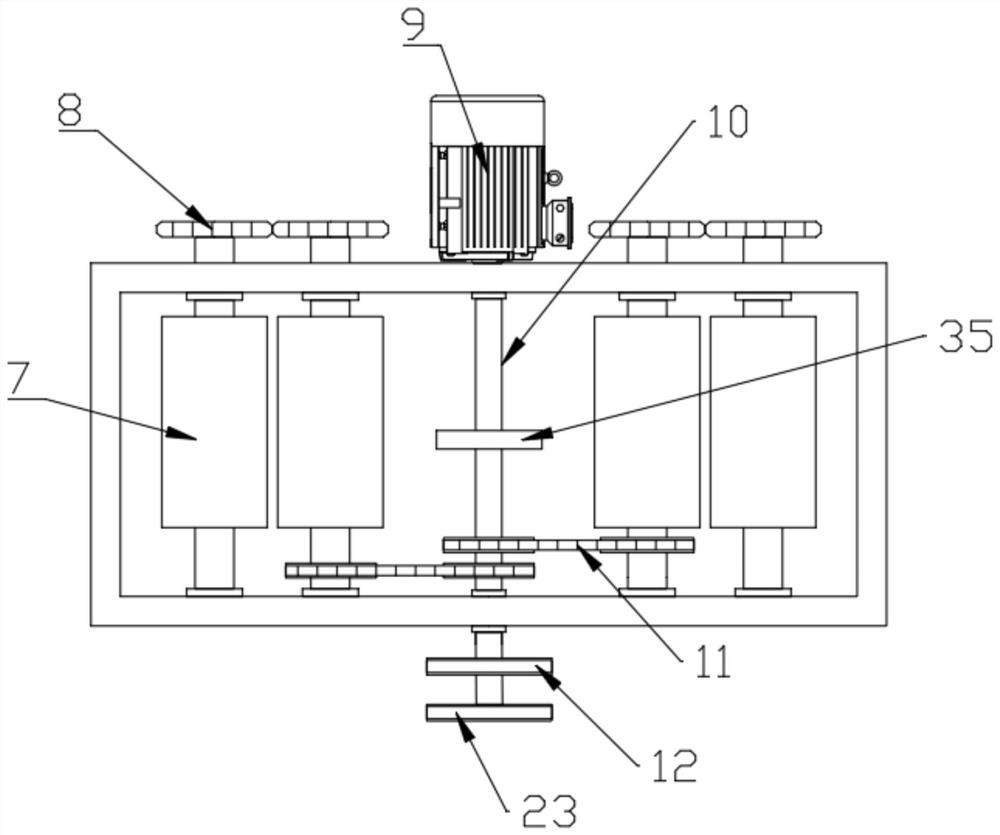

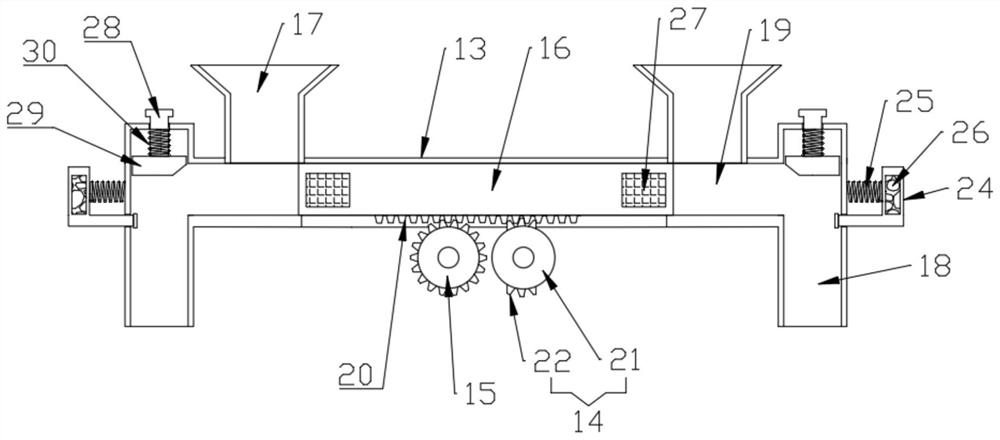

[0026] see Figure 1-6 , an energy-saving and environmentally friendly waste paper crushing and recycling device, comprising an outer shell 1 and an inner pot 2, the outer side of the outer shell 1 is fixedly provided with a bracket 3, the inner pot 2 is fixedly embedded in the outer shell 1, and the inner pot 2 is fixed. A feeding port 4 is opened at the top of the inner pot, and two discharge ports 5 are symmetrically opened at the bottom of the inner pot 2. The inner pot 2 is provided with a pre-crushing mechanism under the feeding port 4, and the outer shell 1 is located in the discharging port. A secondary crushing mechanism is provided below the port 5, and a compression mechanism is provided in the casing 1 below the secondary crushing mechanism. The pre-crushing mechanism includes two first crushing rollers 6, and both of the first crushing rollers 6 rotate. Set in the inner tank 2, the secondary pulverizing mechanism includes two pulverizing units symmetrically arrang...

Embodiment 2

[0031] This embodiment has carried out function expansion on the basis of Embodiment 1, specifically:

[0032] A cavity 31 is opened at the bottom of the inner container 2 between the two discharge ports 5, and an air outlet 32 is opened in the inner container 2 above the cavity 31, and a movable plate is sealed and slidably connected in the cavity 31. 33. A piston rod 34 is fixed on the bottom of the movable plate 33, and a cam 35 is fixed on the rod body of the driving rod 10. The outer side of the cam 35 is in contact with the end of the piston rod 34. The piston rod The end of 34 is fixed with a roller 36, and the piston rod 34 is located above the roller 36 and is fixed with a stopper 37. The rod body of the piston rod 34 located between the stopper 37 and the bottom surface of the inner pot 2 is sleeved with a third The spring 38, by setting the cam 35, the piston rod 34 and the movable plate 33, the driving motor 9 drives the pre-crushing mechanism and the secondary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com