Seamless steel pipe surrounding type intermittent processor

A seamless steel pipe, wrap-around technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low scouring force, cleaning one side alone, low rinsing efficiency, etc., and achieve strong scouring force , Cleaning effect is good, washing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

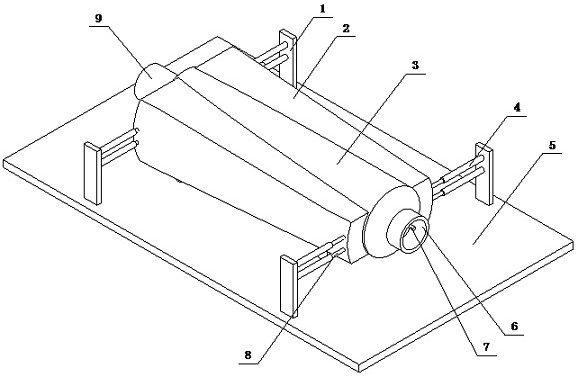

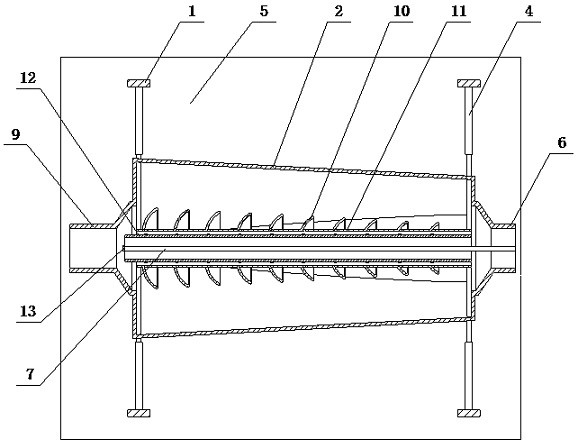

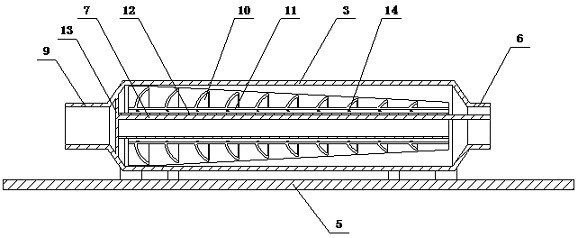

[0016] A seamless steel pipe surrounding batch processing machine of the present invention is realized in this way. It consists of a support device and a flow diversion device. The support device consists of a fixed plate (1), a storage box (2), a flushing main pipe (3), a hydraulic rod ( 4), the base (5), the water inlet pipe (6), the push rod (8) and the water outlet pipe (9), the flushing main pipe (3) is placed on the base (5) through the support seat, two storage boxes (2 ) placed on the outer wall of the flushing main pipe (3) and located on both sides of the flushing main pipe (3) respectively. The longitudinal section of the storage box (2) is arc-shaped, the arc length of one end of the storage box (2) is smaller than the arc length of the other end, and the thickness of one end of the storage box (2) is smaller than that of the other end The storage box (2) communicates with the interior of the flushing main pipe (3) to form a flushing cavity, and the water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com