Low-cost production method of shared hole pattern of channel steel and I-shaped steel

A production method and technology of I-beam, applied in metal rolling and other directions, can solve the problems of high cost of rolls and tooling, long time for product replacement, and high production cost, and achieve the goal of reducing the amount of spare rolls, improving service life and increasing output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

[0011] Because the rolling mill capacity of the profile rolling mill implemented by the present invention is relatively small, the square billet of 150 * 150mm is selected to be rolled in the billet size that the factory can provide.

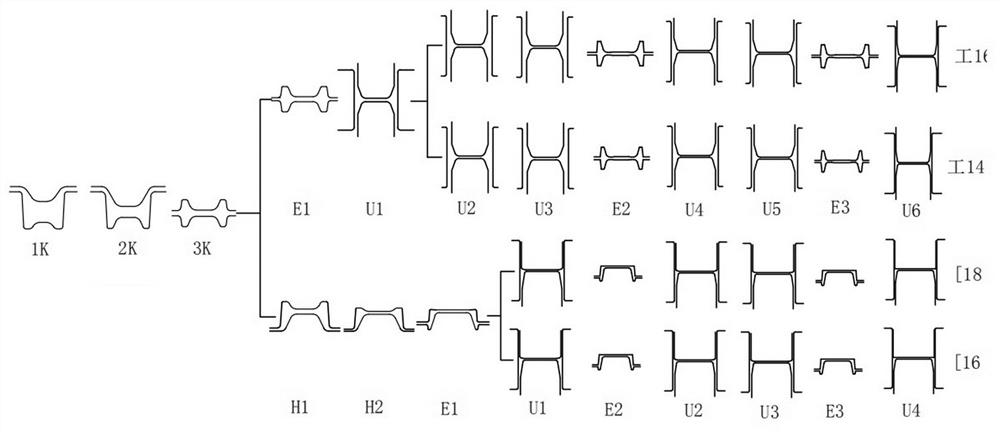

[0012] Attached figure 1 As shown, the BD mill adopts three-pass reciprocating rolling, and the waist extension coefficient is less than 1.8. The purpose is to shorten the rolling time of the BD mill and improve the rolling rhythm under the premise of ensuring the normal biting of the rolled piece.

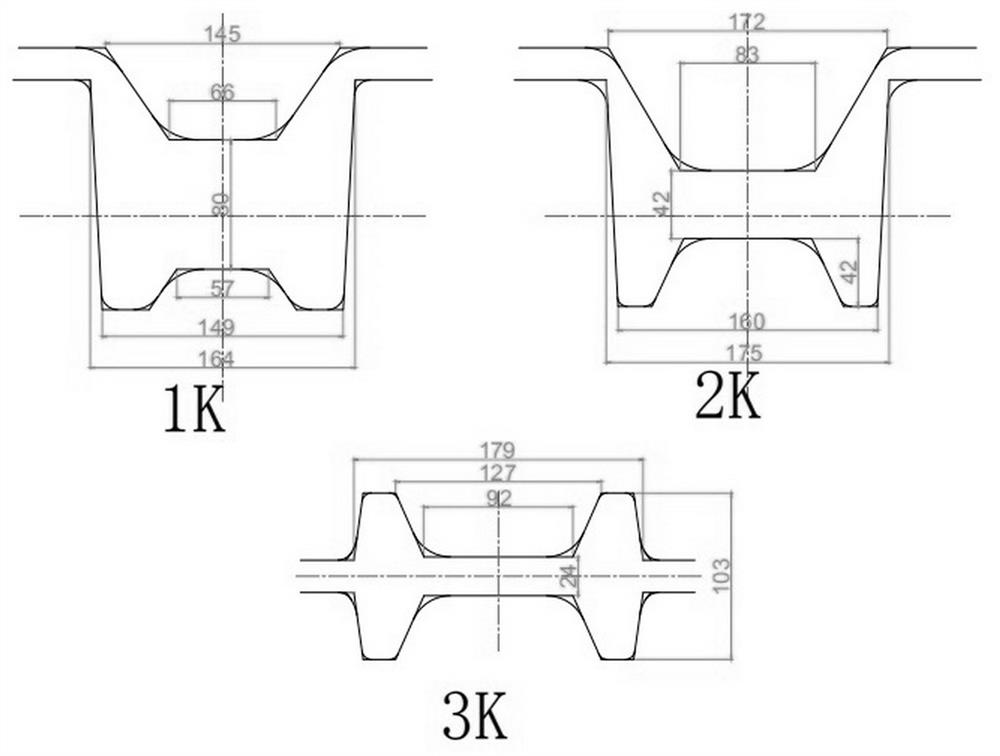

[0013] as attached figure 2 As shown, the purpose of adopting closed pass + closed pass + control pass in the BD mill is to control the width of the final rolling material shape of the BD rolling mill, so as to avoid the excessive waist width of the material shape from rolling small-size products.

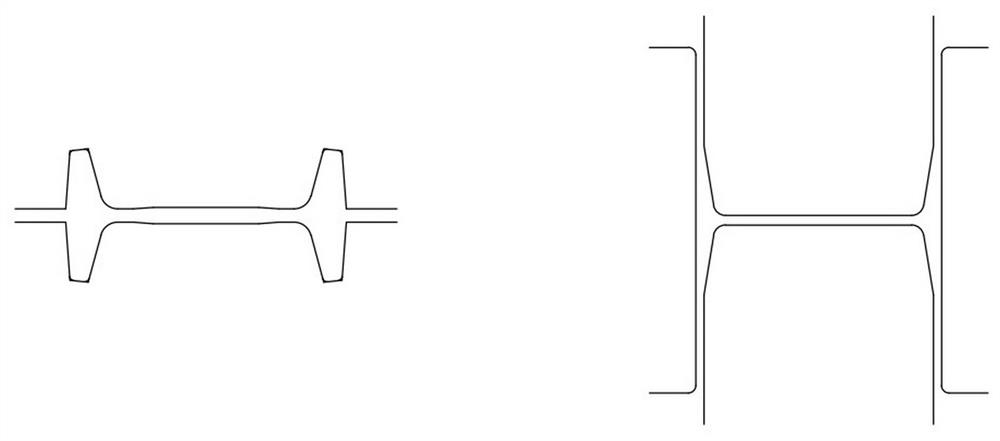

[0014] Each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com