Mechanical production device and process for non-liner down-proof fabric

A technology for fleece-proof fabrics and production equipment, applied in the direction of lamination equipment, layered products, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

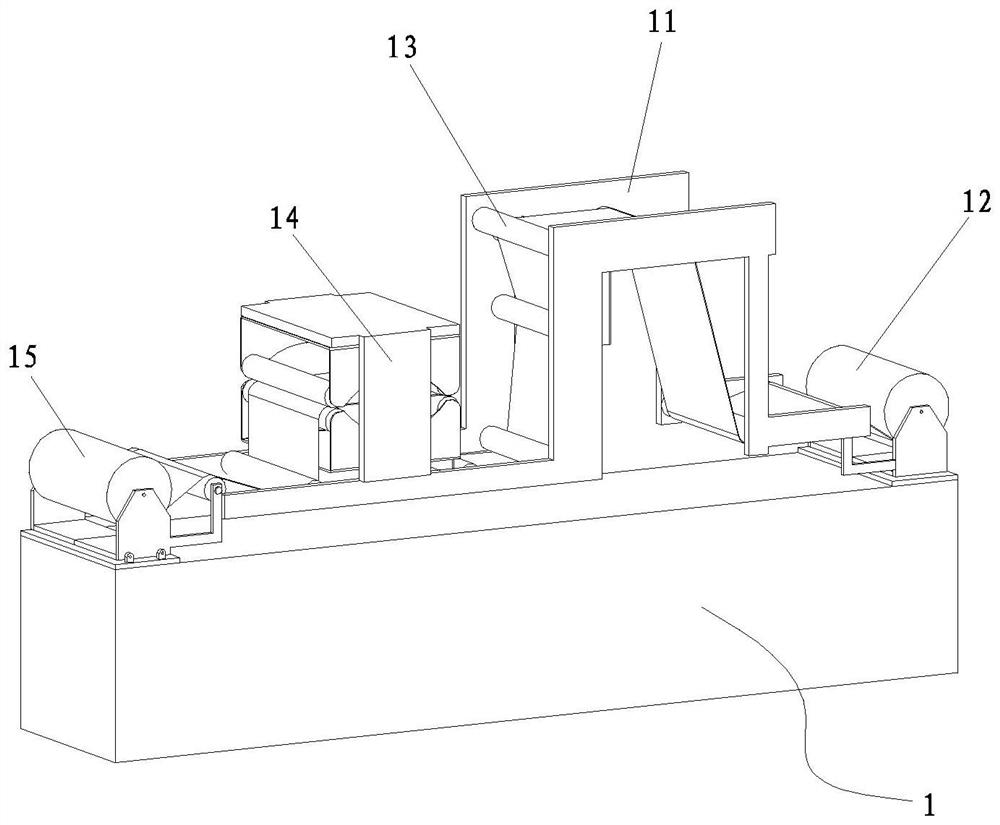

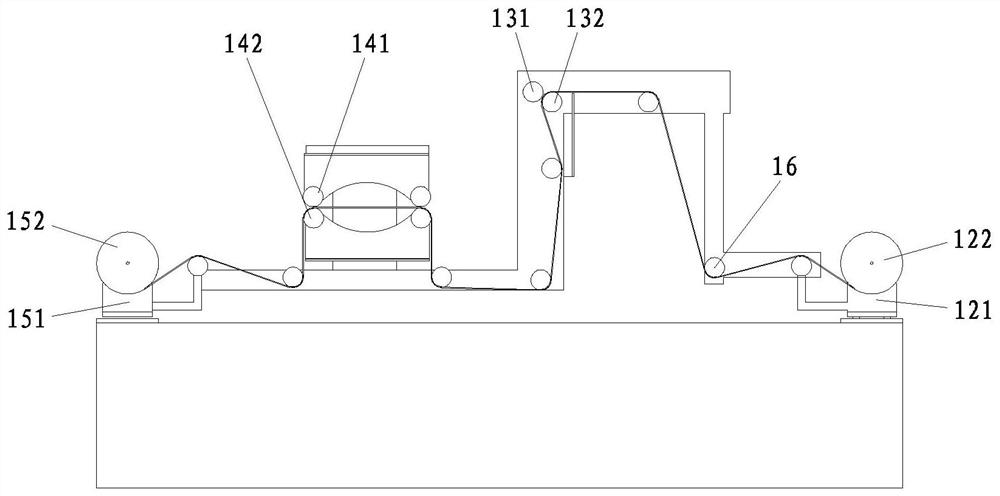

[0041] Such as Figure 1-8 As shown, a mechanized production device for a gutless fleece-proof fabric, which includes a fabric hot-pressing device 1 and a fabric sewing device 2, the fabric hot-pressing device 1 includes a hot-pressing frame 11, and the hot-pressing frame 11 is sequentially provided with Unwinding mechanism 12, pressure roller mechanism 13, heat roller mechanism 14 and first winding mechanism 15, heat roller mechanism 14 comprises heat insulation roller 141 and heating roller 142 that are arranged up and down, heat insulation roller 141 and heating roller 142 and hot pressing The frame 11 is rotatably connected, and the thermal insulation roller 141 and the heating roller 142 can be driven to rotate by driving motors respectively.

[0042] After adopting the above structure, when working, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com