Discharging car hopper structure of constructional engineering cart

A technology for construction engineering and unloading trucks, which is applied in the direction of trolleys, multi-axis trolleys, trolley accessories, etc., and can solve the problems of reducing the convenience of cleaning residual materials in the bucket, unloading residues, and the size of the bucket cannot be adjusted, etc., to improve The effect of convenience and flexible adjustment of length and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

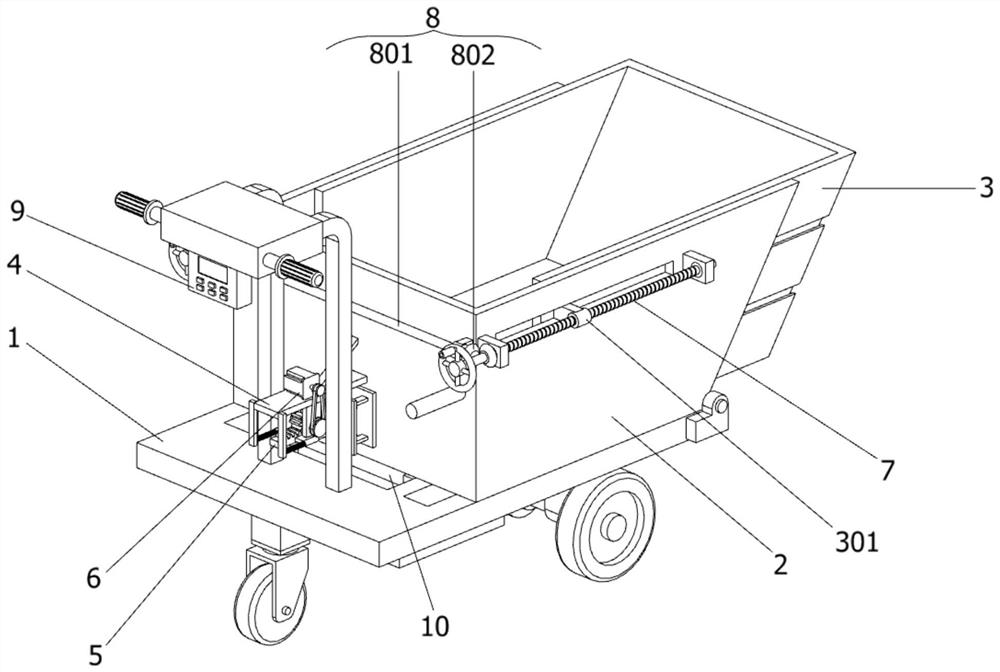

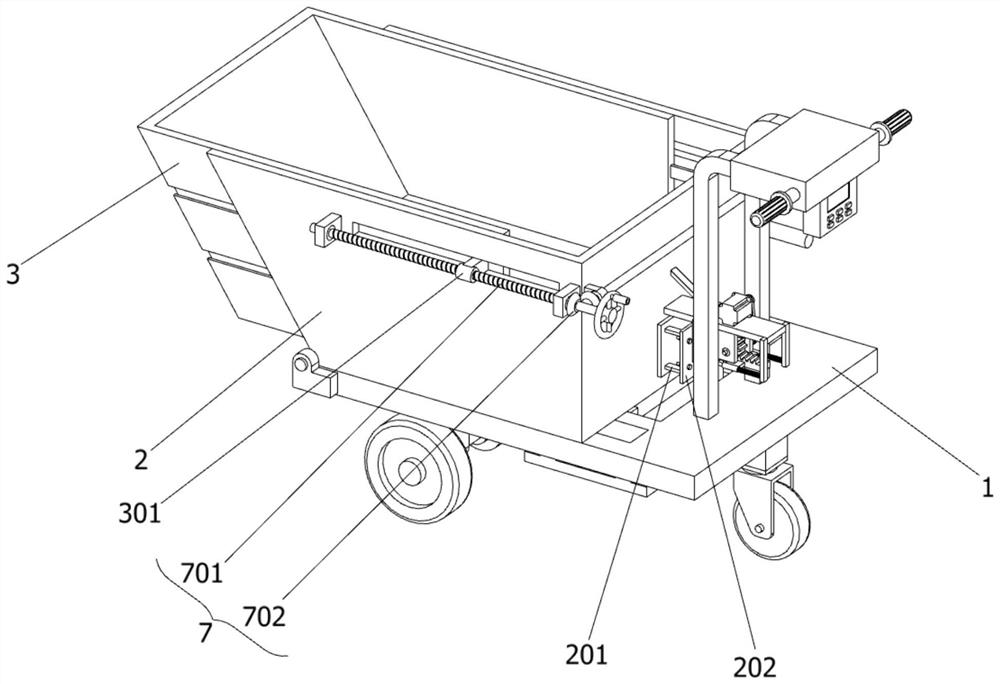

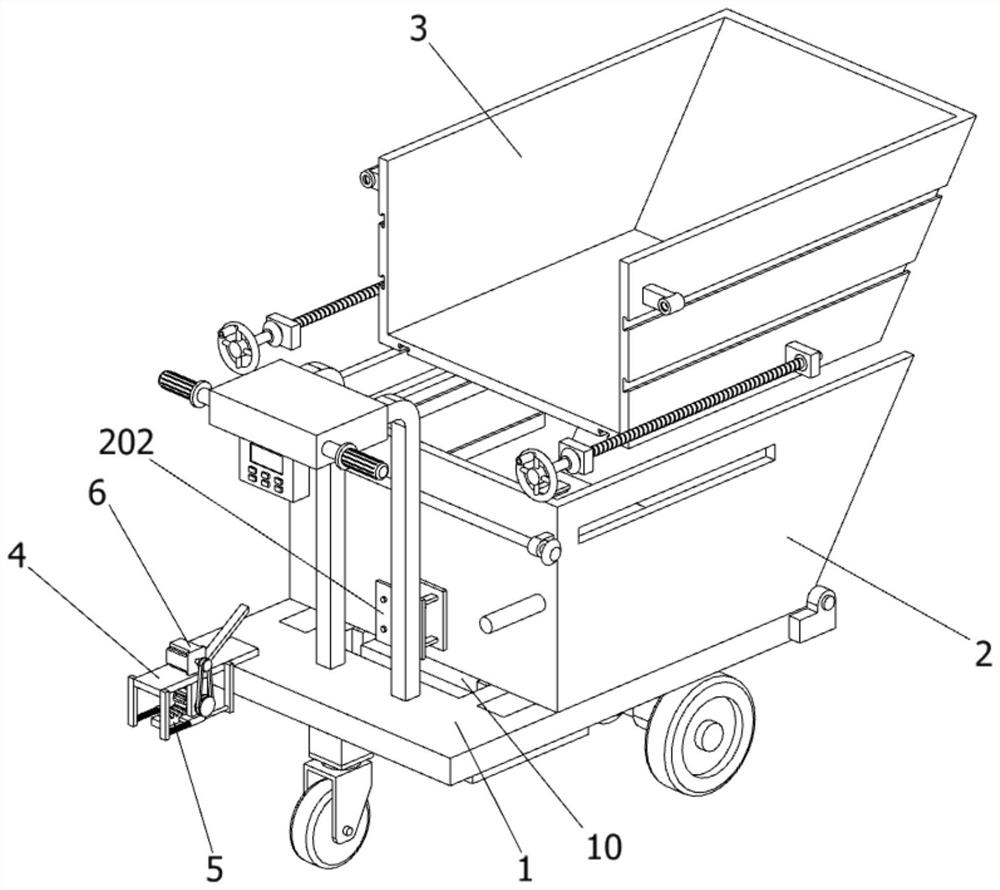

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032]The invention provides an unloading bucket structure of a construction engineering trolley, which includes: a car body 1, a hopper 2 connected to the rear side of the upper end surface of the car body 1 frame through a rotating shaft, and the hopper 2 includes a U-shaped support frame 201 and a vibrating Plate 202, a strip-shaped opening is opened on the left and right ends of the hopper 2, and the lower part of the front end of the hopper 2 is fixedly connected with two square plates. There is a vibrating plate 202, and two T-shaped sliding bars are provided on the bottom end surface and the left and right sides of the hopper 2; the rear side of the hopper 2 is slidingly connected with an extension bucket 3; the extension bucket 3 includes a drive nut 301, and the extension bucket 3 A sliding block is provided on the upper part of the front side of the left and right ends, and a drive nut 301 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com