Automobile part machining automatic conveying device

A technology for automatic conveying devices and auto parts, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy injury, harsh production environment for workers, low production efficiency, etc., to improve safety, reduce Manpower, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

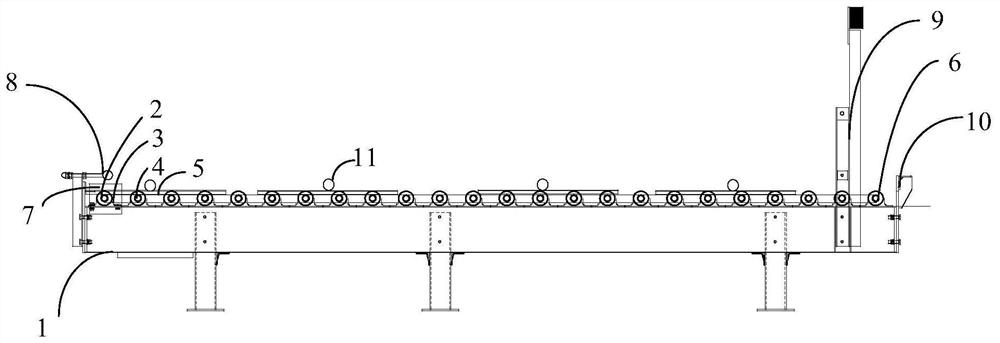

[0015] The present invention proposes an automatic conveying device for auto parts processing, referring to figure 1 , the automatic conveying device for auto parts processing, including: a bracket 1, a transmission mechanism 7, an automatic induction mechanism 8 and a tray pushing mechanism 9, and the bracket 1 is used to provide a fixed support position; in this embodiment, the The support 1 adopts angle steel welding and forming, which has low cost and high stability; the transmission mechanism 7 includes a driving roller 2 arranged at one end of the support 1, a driven roller 6 arranged at the other end of the support 1, a set A plurality of flat rollers 4 between the driving roller 2 and the driven roller 6 and the endless conveyor belt 3 arranged on the driving roller 2 and the driven roller 6; The conveyor belt 3 is wound around the outer circumference of the driving roller 2 and the driven roller 6; the endless conveyor belt 3 rotates along the rotation direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com