Sealing device for processing bottle opening

A sealing device and charging technology, applied in packaging, applications, closures, etc., can solve the problems of high work intensity, slow speed, and many manpower, and achieve the effect of convenient sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

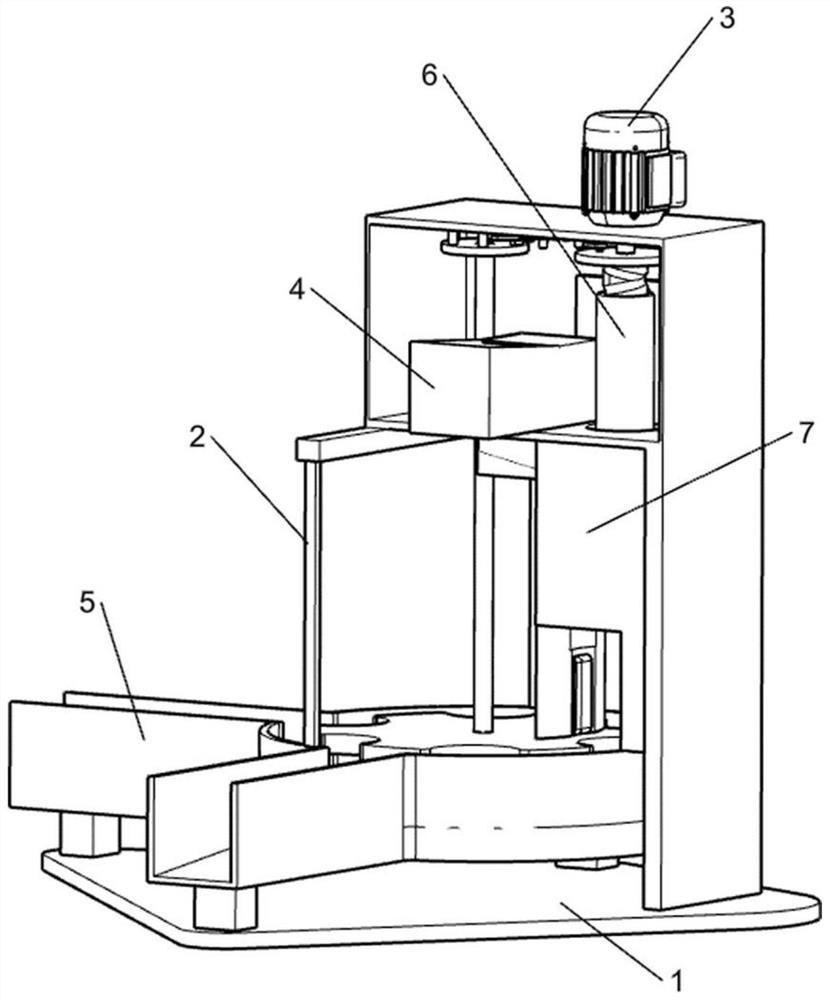

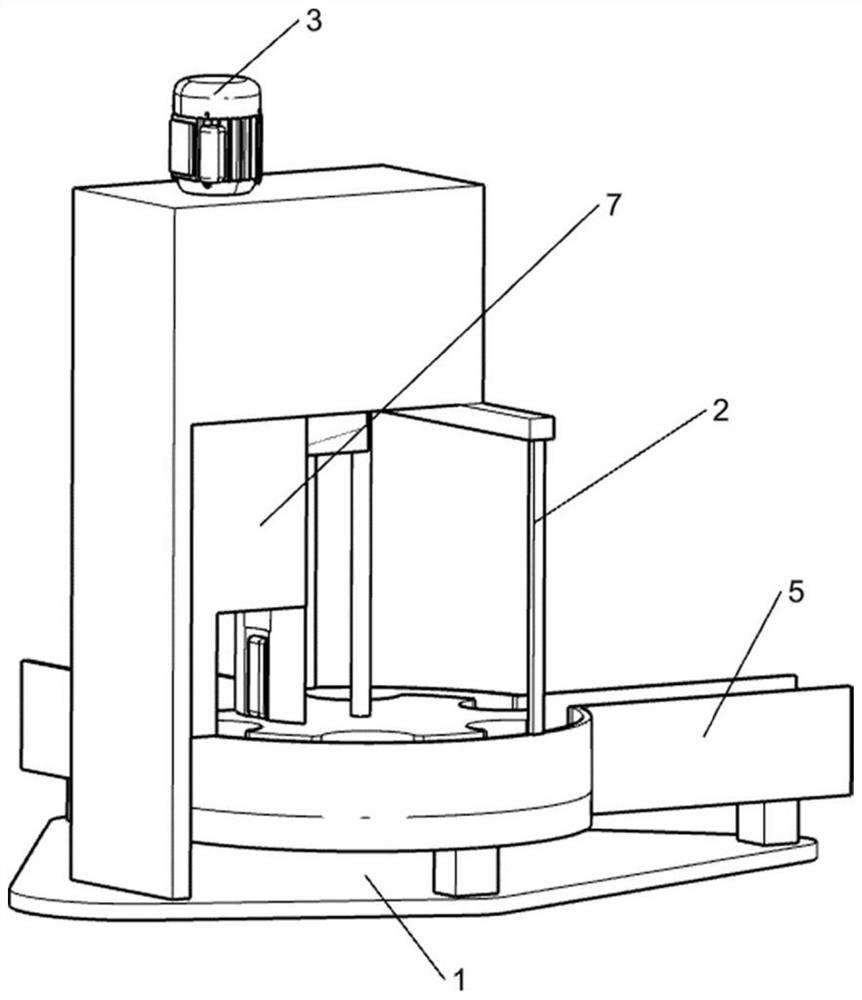

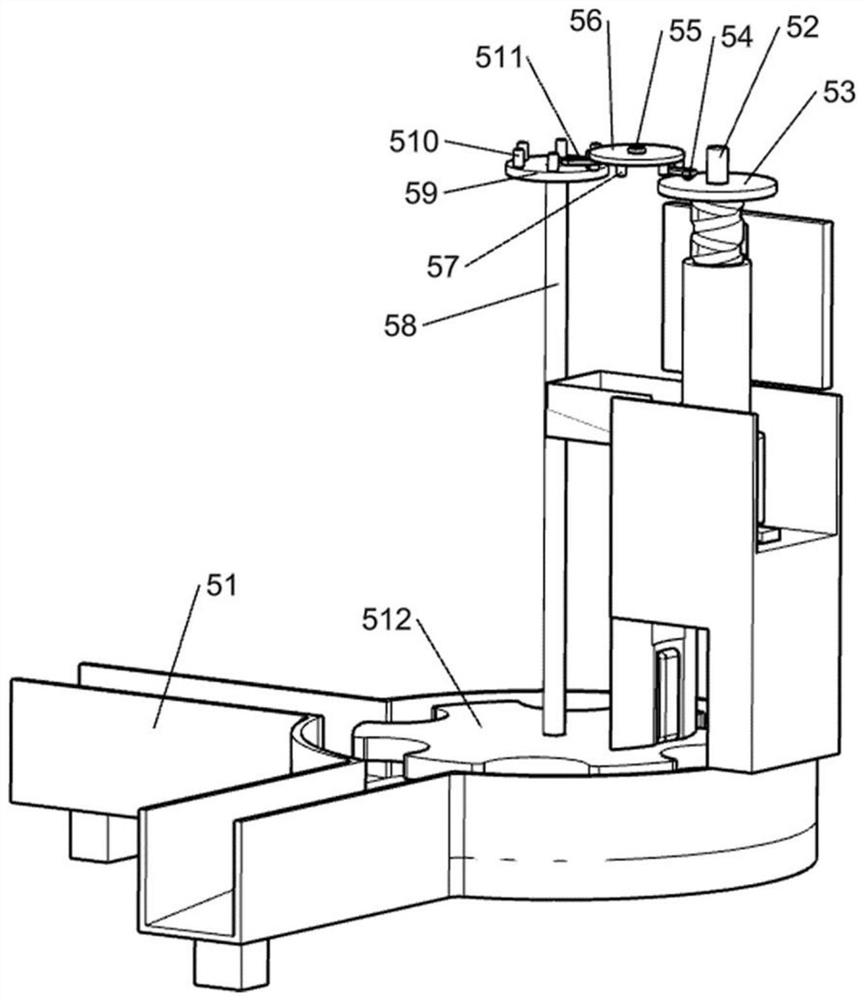

[0024] A sealing device for processing bottle mouths, such as Figure 1-7 As shown, it includes a base support 1, a support frame 2, a drive motor 3, a cover frame 4, a feeding mechanism 5, a sealing mechanism 6 and a clamping mechanism 7, and a pair of support frames 2 are fixedly connected to the bottom of one side of the base support 1. The motor 3 is installed on the top of the base support 1, the driving motor 3 is used to drive the first power shaft 52 and the upper device to rotate forward, the cover frame 4 is fixed on the top of the base support 1, and the cover frame 4 is used to hold the bottle cap. The feeding mechanism 5 is set on the base bracket 1, and through the mutual cooperation between the base bracket 1 and its upper device and the feeding mechanism 5, the bottle to be sealed can be transported and the sealed bottle can slide away from the device. The sealing mechanism 6 is set on the feeding mechanism 5. On the mechanism 5, through the mutual cooperation ...

Embodiment 2

[0030] On the basis of Example 1, such as Figure 7 As shown, an extruding block 8 is also included, and the middle part of the movable sleeve 67 is symmetrically slid to be provided with an extruding block 8, and the extruding block 8 is used to squeeze the two wedge-shaped blocks 73 and the upper clamping block 72 toward the direction of approaching each other. Move, through the mutual cooperation of the clamping mechanism 7 and the extrusion block 8, the bottle can be clamped to prevent the bottle from turning arbitrarily when screwing the bottle cap, and then the effect of screwing the bottle cap will not be affected. The extrusion block 8 and the fixed The bracket 71 is slidably fitted.

[0031] Because the fixed support 71 can clamp the extruding block 8, so the extruding block 8 can move up and down with the movable circular sleeve 67, but can not rotate with the movable circular sleeve 67, when the extruding block 8 moves along with the movable circular sleeve 67 When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com