A feeding device for a material tank in steel processing

A technology of feeding device and material trough, applied in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problem of low efficiency of iron ore, achieve simple principle, be beneficial to manufacturing and maintenance work, avoid iron and steel The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

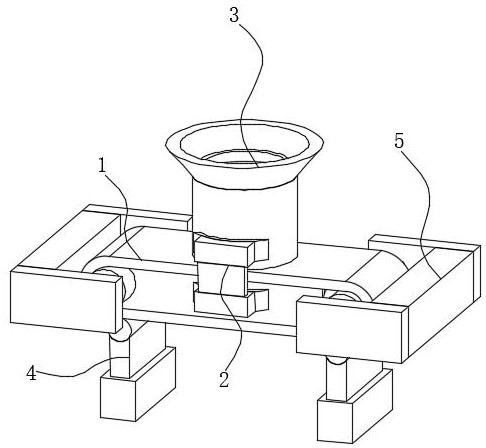

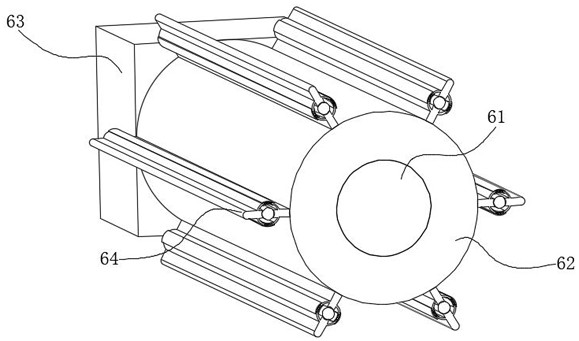

[0032] use Figure 1-Figure 6 A feeding device for a material tank in steel processing according to an embodiment of the present invention will be described below.

[0033] like Figure 1-Figure 6 As shown, a feeding device for a material trough in steel processing according to the present invention includes a feeding device 1, a feeding port is opened in the middle of the inner cavity of the feeding device 1, and the upper surface of the feeding device 1 passes through The feeding port is slidably connected with a storage barrel 3, both sides of the inner cavity of the feeding device 1 are fixedly connected with connecting arms 2, and both ends of the feeding device 1 are rotatably connected with a power device 5. A support base 4 is slidably connected to the lower surface;

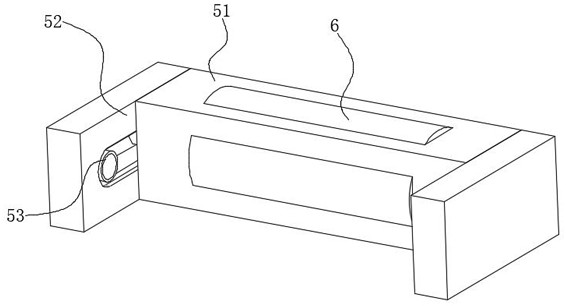

[0034] The power device 5 includes a hollow connecting rod 51 , an auxiliary rotating rod 6 is arranged inside the hollow connecting rod 51 , and a transmission guide plate 52 is fixedly connected to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com