Peroxide value detection pretreatment equipment

A peroxide value and pre-treatment technology, applied in the preparation of test samples, filtration separation, chemical instruments and methods, etc., can solve the problems that impurities and water cannot be completely removed, it takes a long time, and samples are exposed to oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

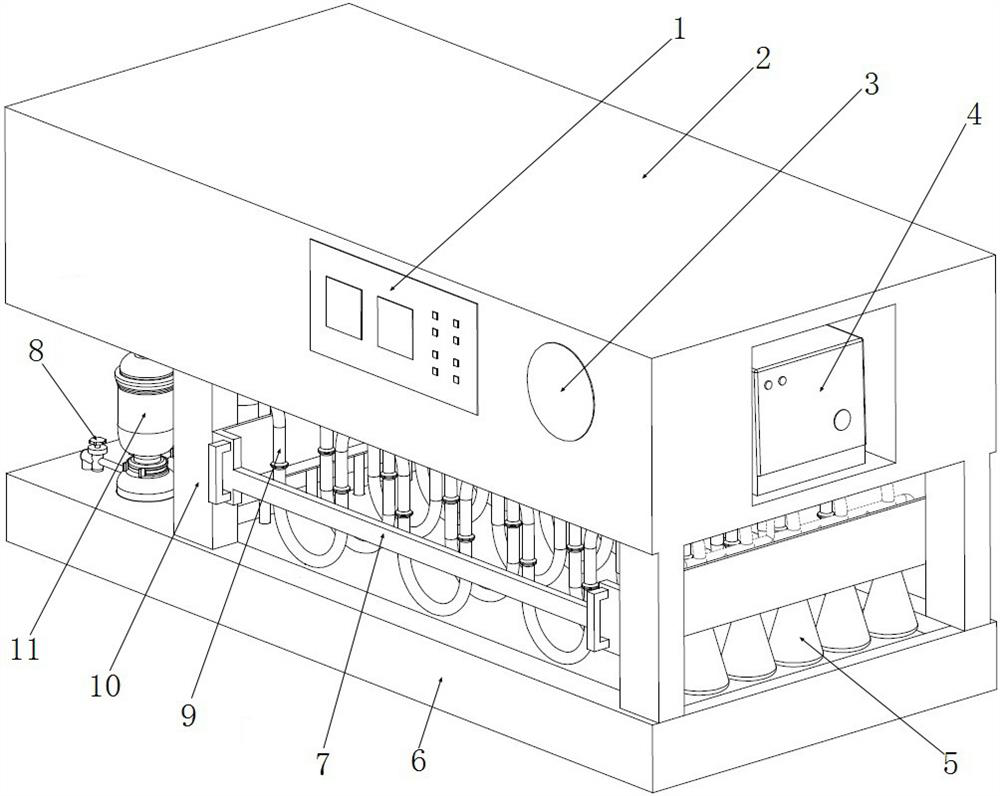

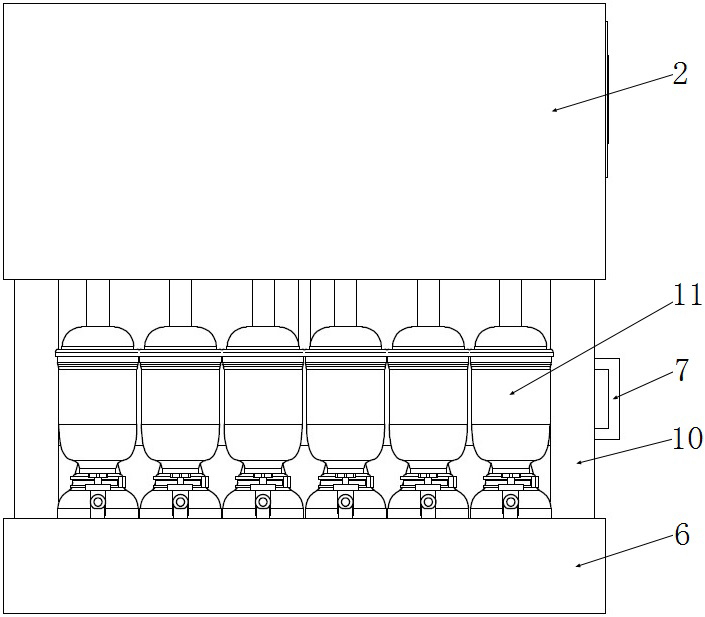

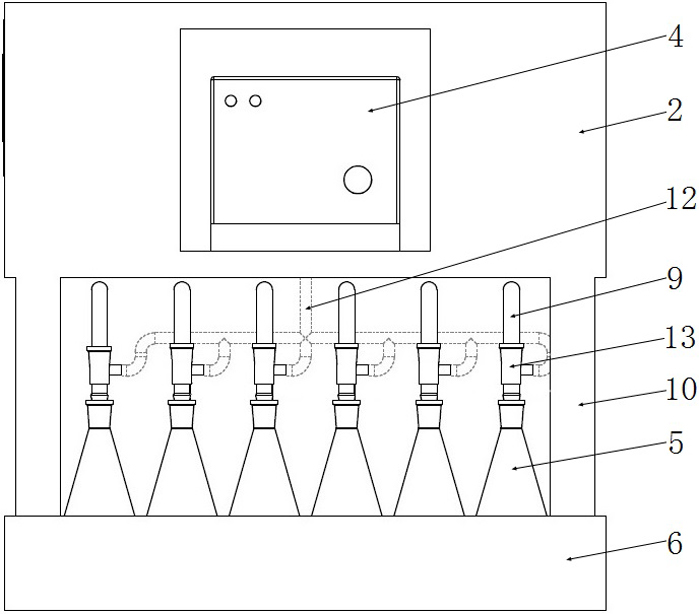

[0034] An embodiment of peroxide value detection pre-processing equipment in the present invention is as figure 1 As shown, a base is included, and the base includes a bottom plate 6 and four uprights 10 fixed on the bottom plate 6 , and the top of the uprights 10 is fixed with a housing 2 .

[0035] combine figure 2 As shown, the left end of the bottom plate 6 is provided with six liquid storage bottles 11 along the front and back direction, and the liquid storage bottles 11 are used to store samples to be filtered. The structure of liquid storage bottle 11 is as Figure 6 As shown, it includes a bottle cap 111, an upper liquid storage bottle 114, and a lower liquid storage bottle 116. The upper liquid storage bottle 114 and the lower liquid storage bottle 116 are detachably connected together through a bottle mouth clip 115, and the bottle cap 111 is installed on the upper liquid storage bottle. The top of the bottle 114 is provided with a gasket 112 at the joint position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com