Drawing frame

A drawing frame and machine technology, which is used in spinning machines, textiles and papermaking, drafting equipment, etc. Good effect, reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

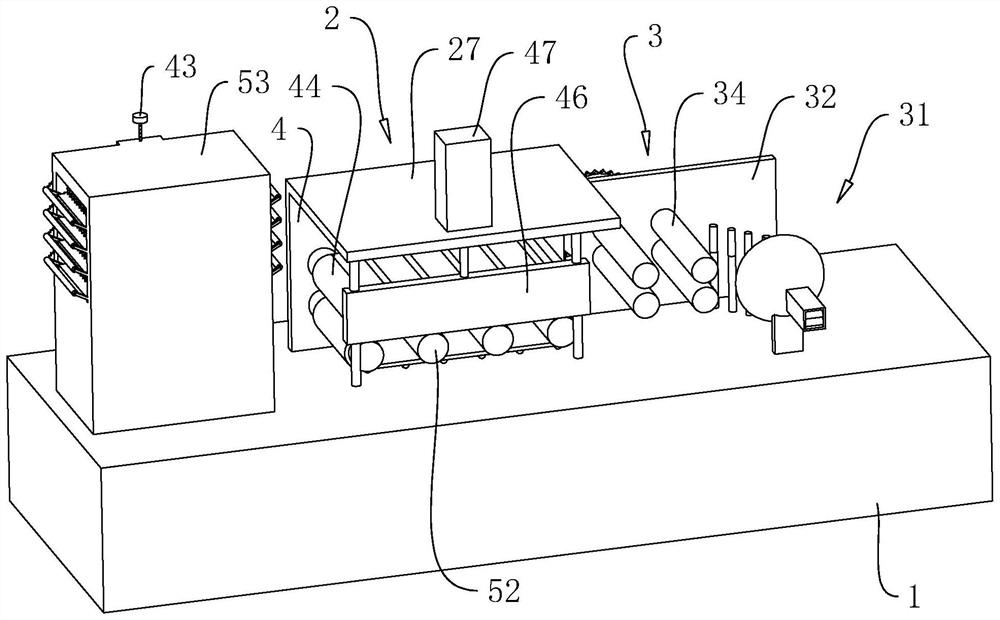

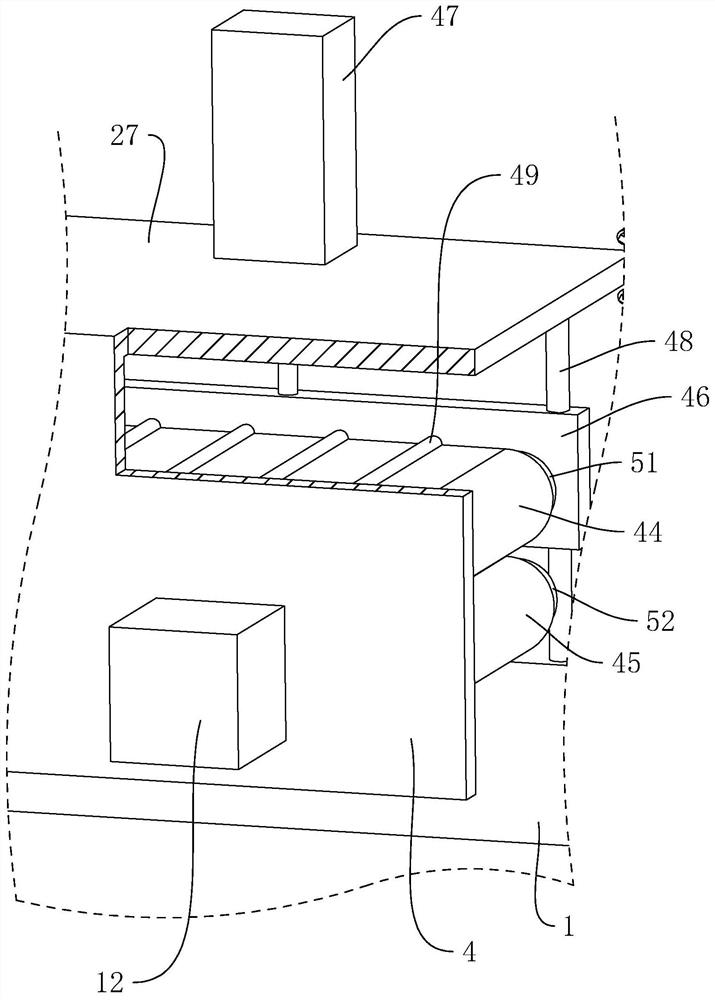

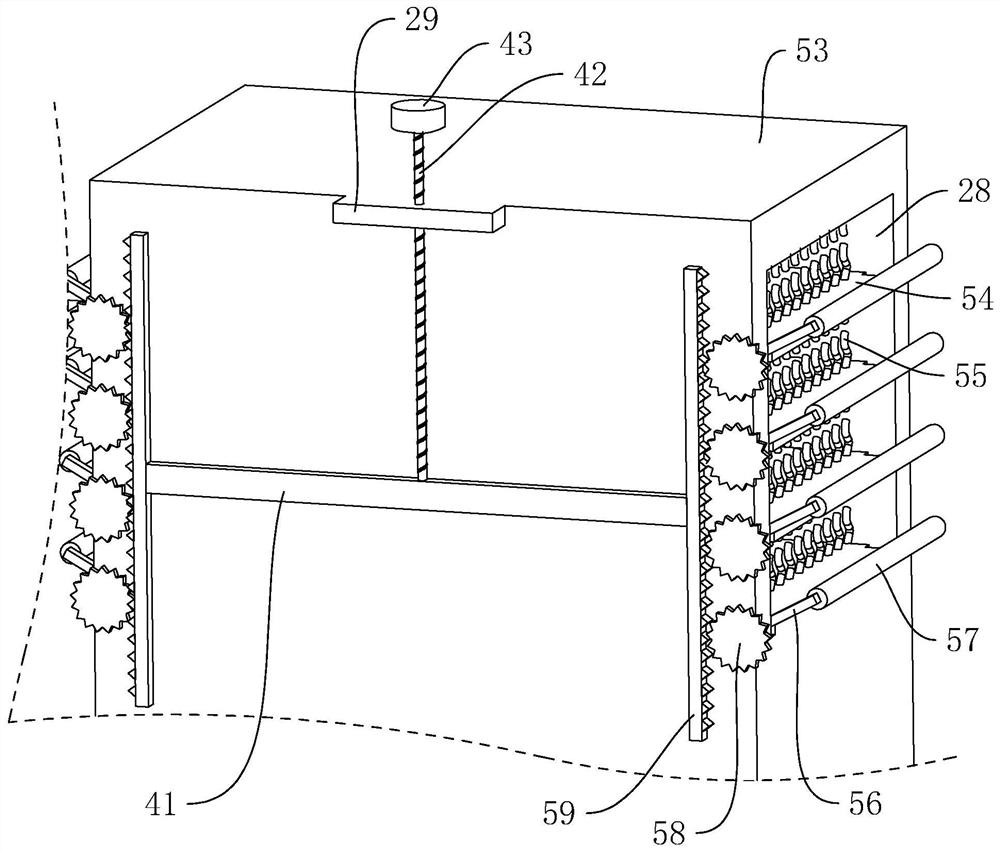

[0038] The application will be described in further detail below in conjunction with all the accompanying drawings.

[0039] The embodiment of the present application discloses a draw frame, referring to figure 1 , including a machine 1 whose length direction is parallel to the sliver transmission direction, the upper surface of the machine 1 is horizontal, and the upper surface of the machine 1 is sequentially installed along the sliver transmission direction to combine several sliver into one sliver Device 2, a drafting device that elongates and thins the completed and combined sliver 3, a merging device 31 that combines the finished sliver into one, and a coiler is provided behind the merging device 31 to process the processed cotton The sliver is placed neatly into the sliver can.

[0040] refer to figure 1 and figure 2, and the device 2 includes a roller plate 4 fixedly connected to the upper surface of the machine platform 1, the longitudinal direction of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com