Building construction transportation hanging basket

A technology for building construction and hanging baskets, applied in the directions of construction, building structure, housing structure support, etc., can solve the problems of inability to remove, insufficient lubrication, and long time consumption of hanging baskets, so as to improve the smoothness of movement and the convenience of use. Fast, reduced shipping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

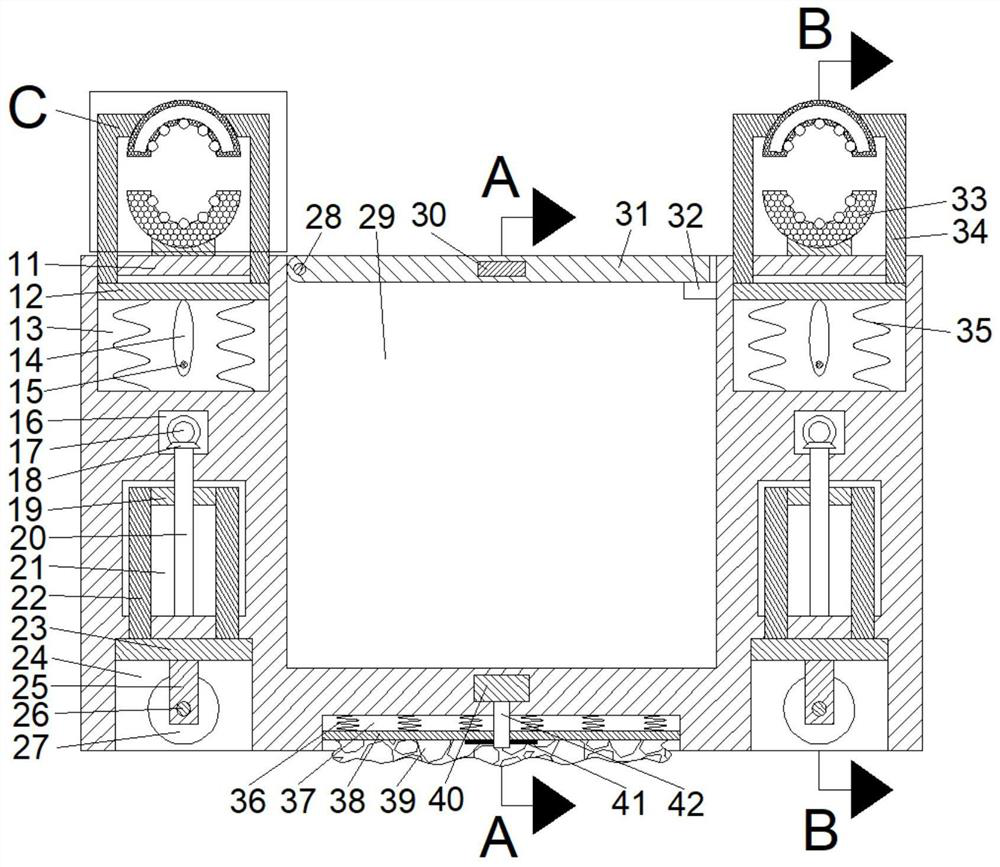

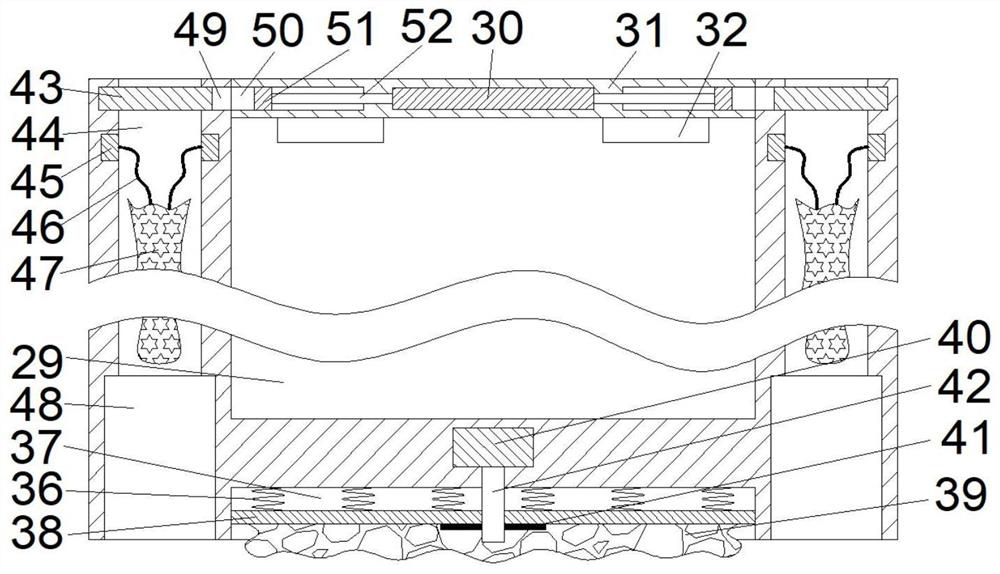

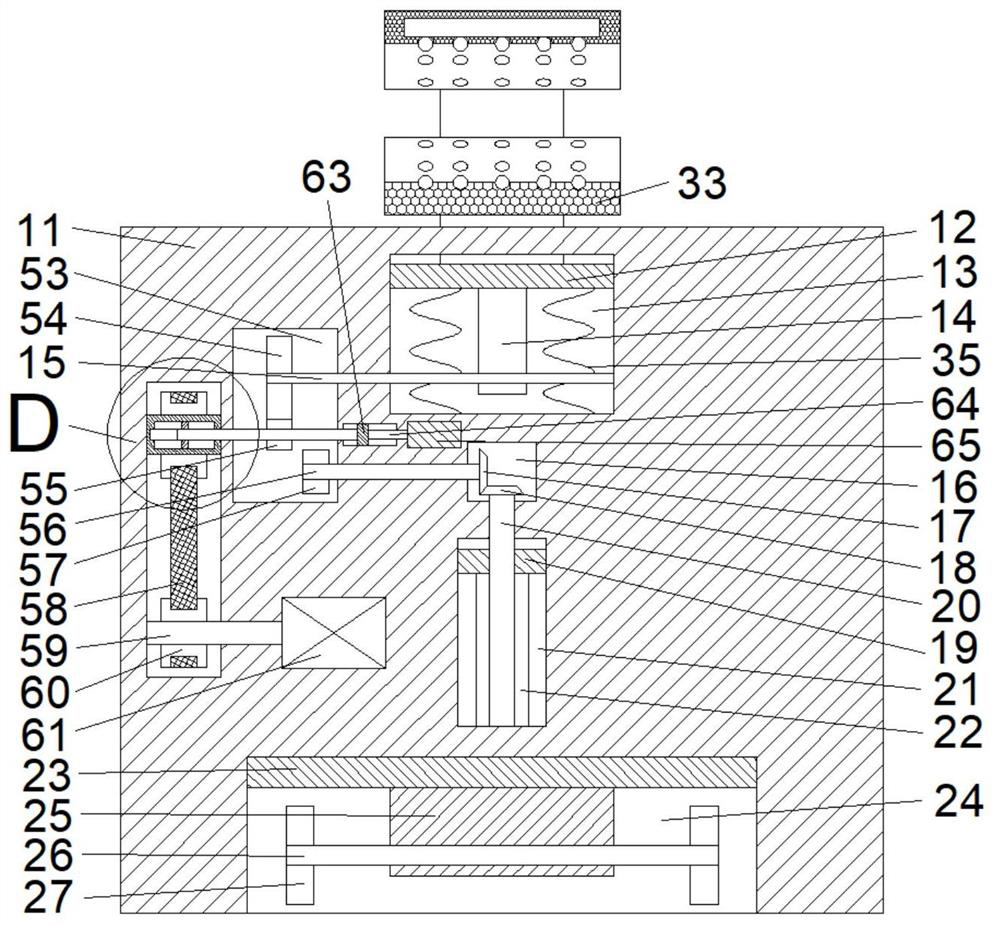

[0024] The structure of the building construction transport hanging basket of the embodiment of the present invention is as Figure 1 to Figure 5 The hanging basket main body 11 is shown in the drawing, and the hanging basket cavity 29 with the opening facing upwards is arranged in the hanging basket main body 11. Self-lubricating devices are symmetrically arranged on the left and right sides above the hanging basket cavity 29, and the self-lubricating devices include symmetrically arranged in the hanging basket cavity 29 The cam cavity 13 on the left and right sides of the top is provided with a slide plate 12 sliding up and down in the cam cavity 13, and the upper end surface of the slide plate 12 is fixedly provided with an L-shaped block 34 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com