Ultra-narrow linear light-emitting surface assembly type lighting system

A technology of ultra-narrow line type and light-emitting surface, which is applied in the field of architectural decoration engineering. It can solve the problems of easy light leakage, breakpoints, and inconvenient installation on the light-emitting surface, and achieve the goals of solving splicing difficulties, facilitating assembly, and improving construction speed and construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

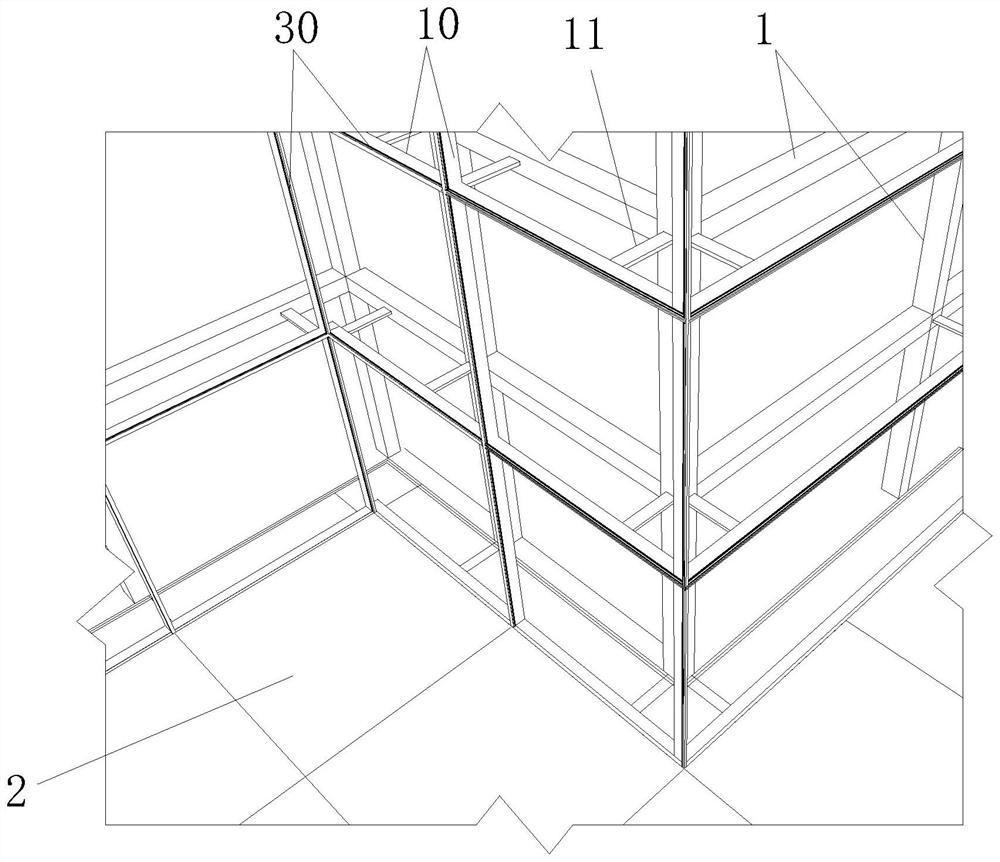

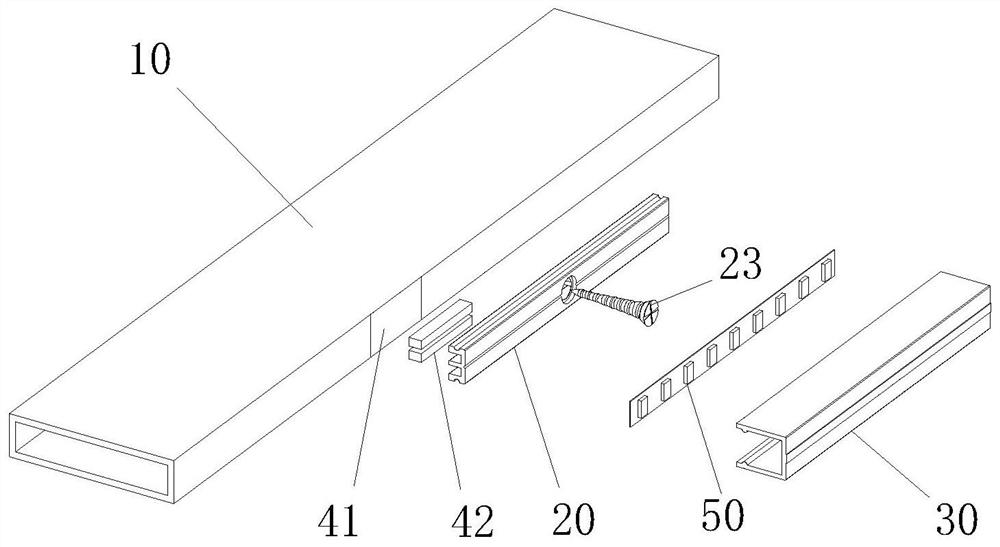

[0069] This embodiment provides an ultra-narrow line light-emitting surface lighting system, combined with figure 1 and figure 2 As shown, the lighting system includes a suspension frame 10 , a lamp holder 20 , a lampshade 30 , an iron sheet 41 , a magnet 42 and an LED light strip 50 arranged along the wall and the top.

[0070] Wherein, the suspension frame 10 is a rectangular steel pipe, such as a rectangular steel pipe with a cross-sectional size of 40 mm×10 mm and a thickness of 1.5 mm, and the height of the suspension frame 10 is only 10 mm. When the lamp holder 20 is located in the plane section of the suspension frame 10, the lamp holder 20 is arranged on the 10mm side of the rectangular steel pipe; on one side. The suspension frame 10 on the wall is fixedly connected to the keel 1 of the partition wall system through the connecting rod 11, and the connecting rod 11 is also a rectangular steel pipe with a cross-sectional size of 40mm×10mm and a thickness of 1.5mm. T...

Embodiment 2

[0075] This embodiment provides a construction method for an ultra-narrow line light-emitting surface lighting system, combined with Embodiment 1 and Figure 1 to Figure 19 Shown, described construction method comprises the steps:

[0076] A suspension frame 10 is arranged along the wall surface and the top, and the suspension frame 10 on the wall surface is fixedly connected with the keel 1 of the partition wall system through a connecting rod 11; And the spacing matches the decorative joints on the ground;

[0077] A plurality of iron sheets 41 are arranged at intervals on the suspension frame 10; a plurality of magnets 42 are arranged in the cavity 21 of the lamp holder 20; Be fixed on the suspension frame by screws 23;

[0078] Fix the LED light strip 50 on the lamp holder 20;

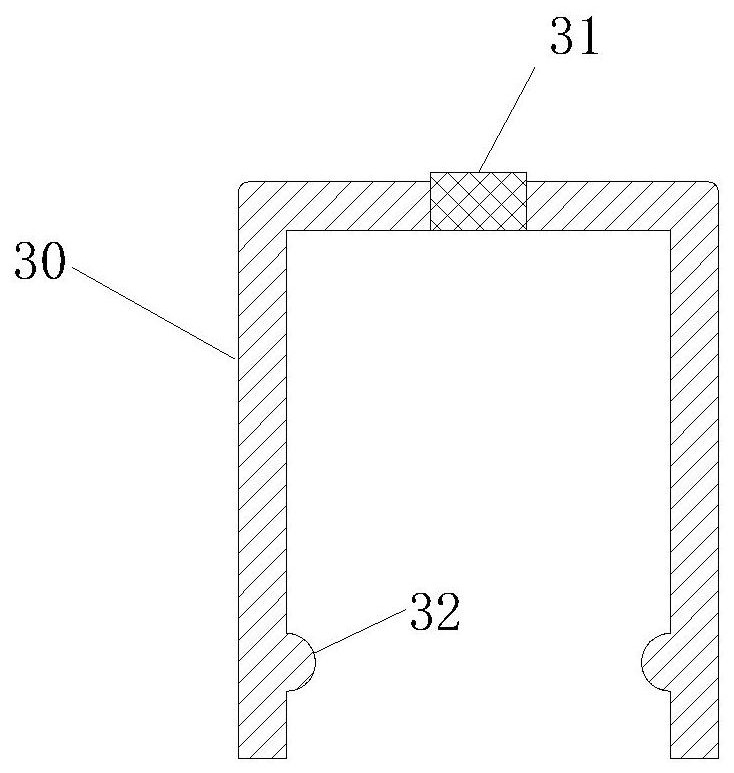

[0079] The lampshade 30 is snapped into the slot 22 on the lamp holder 20 through the clip bar 31 .

[0080] A preferred embodiment is that the lampshade 30 is made of transparent resin materia...

Embodiment 3

[0082] combine Figure 6 to Figure 19 As shown, the suspension frame 10 of the ultra-narrow-line light-emitting surface lighting system includes a plane segment suspension frame 101, a positive corner segment suspension frame 102, and a negative corner segment suspension frame 103. Therefore, the lamp holder 20 and the lampshade 30 have different cross-sectional forms . The lamp holder 20 includes a plane segment lamp holder 201 , a male corner segment lamp holder 202 , and a female corner segment lamp holder 203 .

[0083] figure 2 The suspension frame displayed is a plane section suspension frame, Figure 3 to Figure 5 The lamp holder displayed is a flat segment lamp holder, and the lampshade is a flat segment lampshade. Figure 2 to Figure 5 It has been described in Embodiment 1, and will not be repeated here.

[0084] Image 6 A schematic structural diagram of the lighting system at the cross node of the suspension frame 101 in the plane section is shown. During ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com