Steel bar diameter measuring device

A technology for diameter measurement and steel bars, which is applied in the field of steel bar diameter measurement devices, can solve problems such as cumbersome operation and affecting measurement efficiency, and achieve the effect of improving efficiency and increasing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

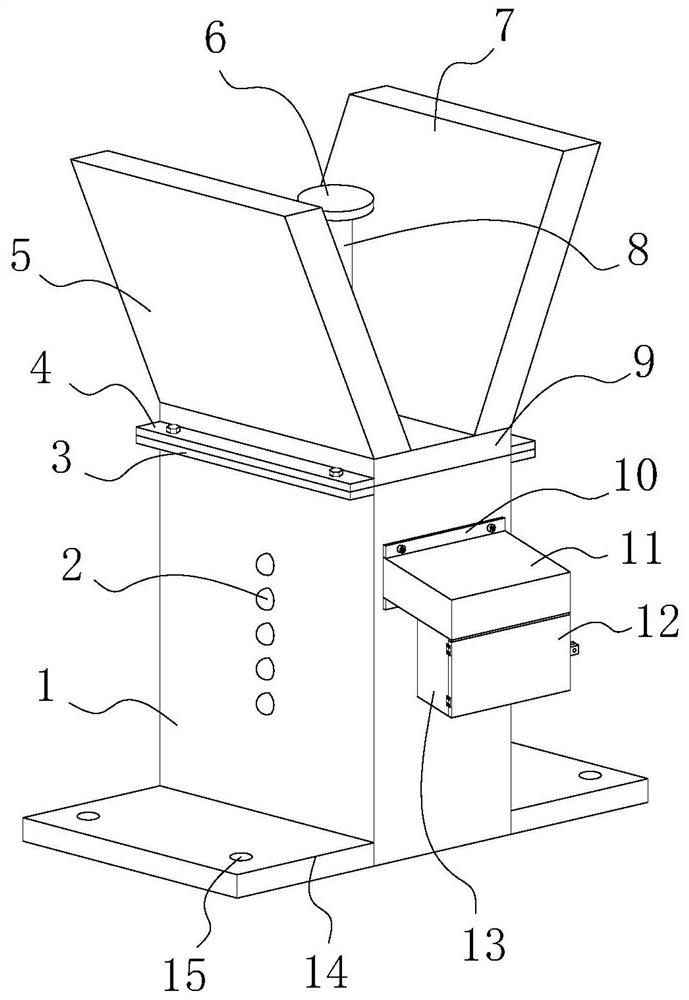

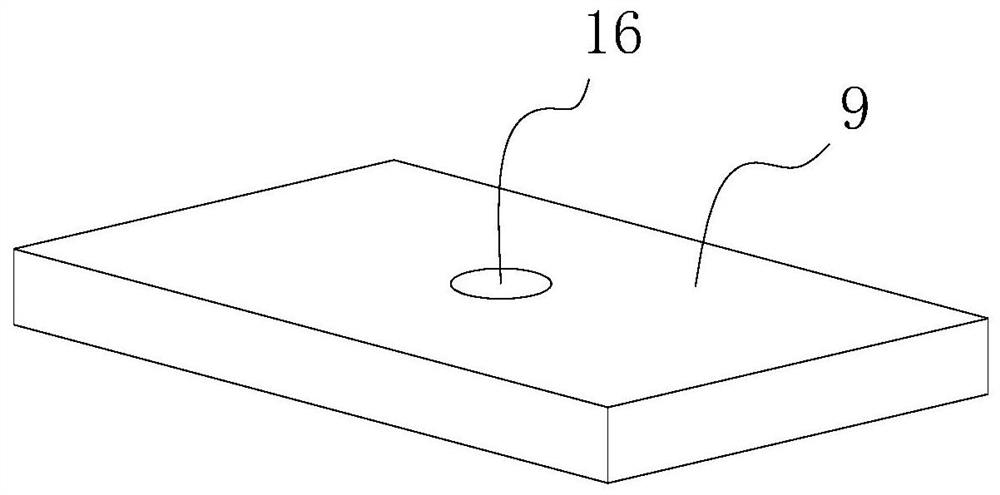

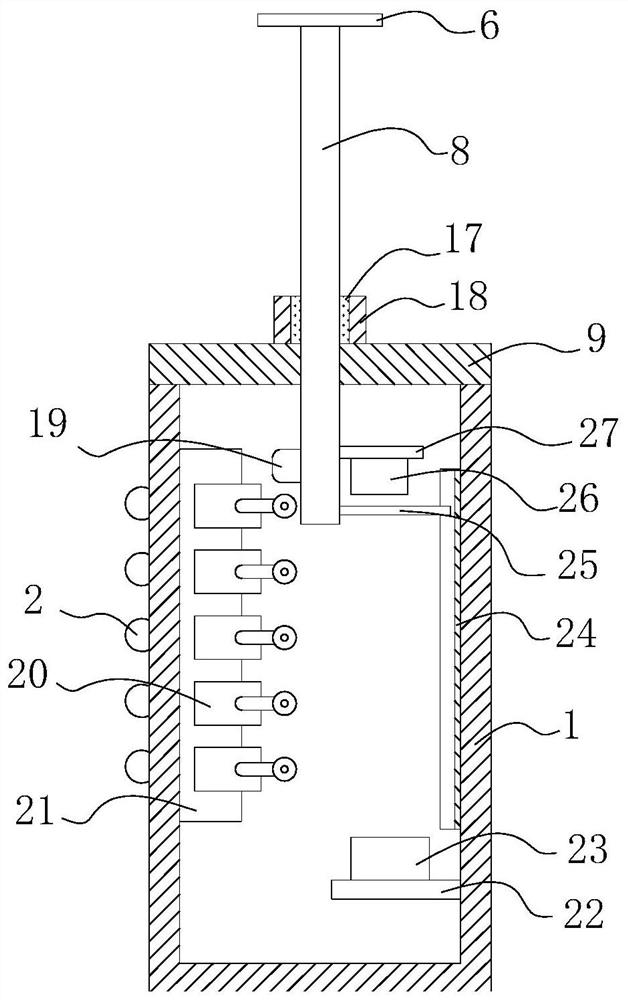

[0044] The specific embodiment: according to the diameter of different steel bars, several travel switches 20 are arranged on the carrier plate 21, so that after a steel bar of one size is placed between the first baffle plate 5 and the second baffle plate 7, the pressure rod 8 is placed between the steel bars. Squeeze down to drive the briquetting block 19 to move downward, and make the briquetting block 19 squeeze the corresponding travel switch 20, because the first baffle plate 5 and the second baffle plate 7 jointly form a V-shaped structure that limits the position of the steel bar, and then the steel bar When placed horizontally between the first baffle plate 5 and the second baffle plate 7, the pressure rod 8 slides down along the rubber sleeve 17 under the extrusion of the steel bar, so that the pressure block 19 moves to the position corresponding to the steel bar of the corresponding size. Squeeze the travel switch 20 at the travel switch 20, the rest of the travel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com