Processing technology of black tea

A processing technology, black tea technology, applied in the field of black tea processing technology, can solve the problems of poor black tea quality, inability to fully exert the effect of black tea, roughness, etc., and achieve the effect of improving soup color, reducing tea greenness and astringency, and improving aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

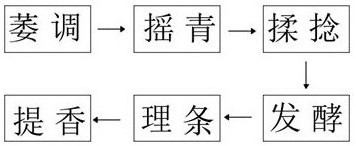

Image

Examples

Embodiment 1

[0022] Embodiment one: a kind of processing technology of black tea is characterized in that comprising the steps:

[0023] 1) Withering: spread the fresh tea evenly on the withering tank at a temperature of 20 degrees Celsius, and let it stand for 13 hours. The thickness of the tea spread on the withering tank is 18 cm. During the withering period, it needs to be turned every 20 minutes. To make the withering uniform, the next process can be carried out when the color of the tea green leaves turns dark green, the surface luster disappears, and the hand feels soft and even;

[0024] 2) Shaking: After the withering is over, transfer the fresh tea leaves to a green shaker for 35 minutes. The shaking speed increases from low to high, and the force gradually grows from light to light.

[0025] 3) Kneading: After shaking the green leaves, transfer the tea leaves to a kneading machine for kneading. The temperature is controlled at 25 degrees Celsius and the humidity is controlled at...

Embodiment 2

[0030] Embodiment two: a kind of processing technology of black tea is characterized in that comprising the steps:

[0031] 1) Withering: Spread the fresh tea evenly on the withering tank at a temperature of 23 degrees Celsius, and let it stand for 14 hours. The thickness of the tea spread on the withering tank is 18.5 cm. During the withering period, turn it every 25 minutes. In order to wither evenly, the next process can be carried out when the color of tea green leaves turns dark green, the surface luster disappears, and the hand feels soft and even;

[0032] 2) Shaking: After the withering is over, transfer the fresh tea leaves to the green shaking machine for 40 minutes. The shaking speed increases from low to high, and the force gradually grows from light to light.

[0033] 3) Kneading: After shaking the green leaves, transfer the tea leaves to a kneading machine for kneading. The temperature is controlled at 25 degrees Celsius and the humidity is controlled at 43%. Kne...

Embodiment 3

[0038] Embodiment three: a kind of processing technology of black tea is characterized in that comprising the steps:

[0039] 1) Withering: Spread the fresh tea evenly on the withering tank at a temperature of 22 degrees Celsius, and let it stand for 15 hours. The thickness of the tea spread on the withering tank is 19 cm. During the withering period, it needs to be turned every 30 minutes. To make the withering uniform, the next process can be carried out when the color of the tea green leaves turns dark green, the surface luster disappears, and the hand feels soft and even;

[0040] 2) Shaking green: After the withering is over, transfer the fresh tea leaves to the green shaking machine and shake the green leaves for 45 minutes. The speed of shaking green leaves gradually increases from low to high, and the force gradually increases from light to green.

[0041] 3) Kneading: After shaking the green leaves, transfer the tea leaves to a kneading machine for kneading. The tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com