A high-precision chamfering processing mold and method

A technology for processing molds and high precision, applied in the field of high-precision chamfering molds, can solve the problems of high positioning and coordination requirements, low chamfering efficiency, low precision, etc., and achieve the effect of simple and efficient processing control and elimination of errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

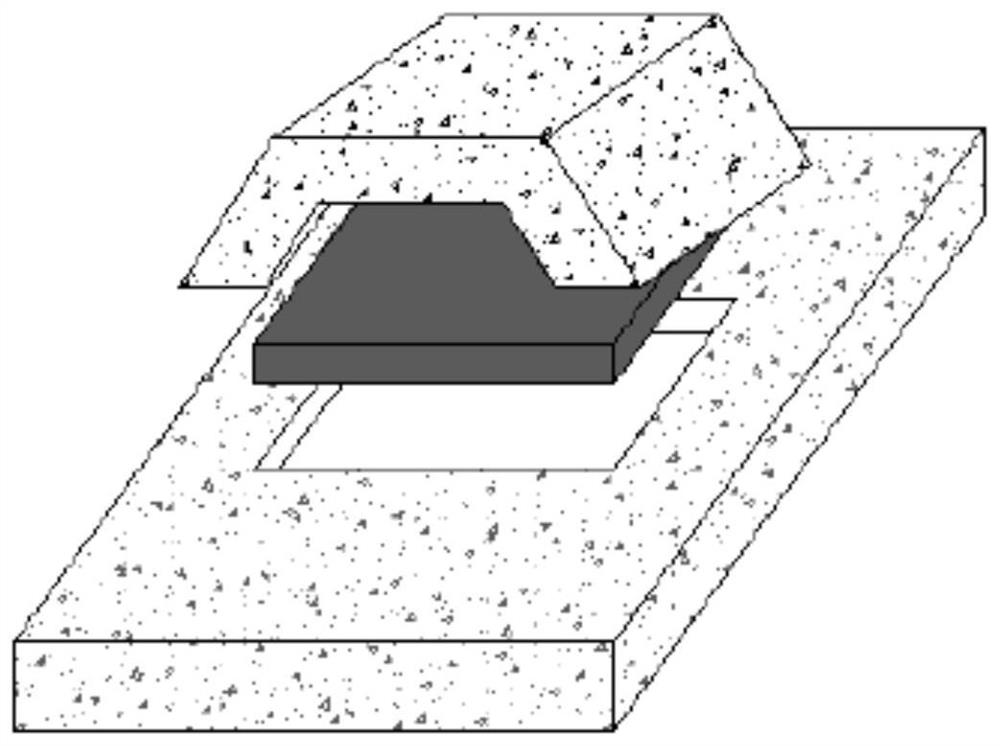

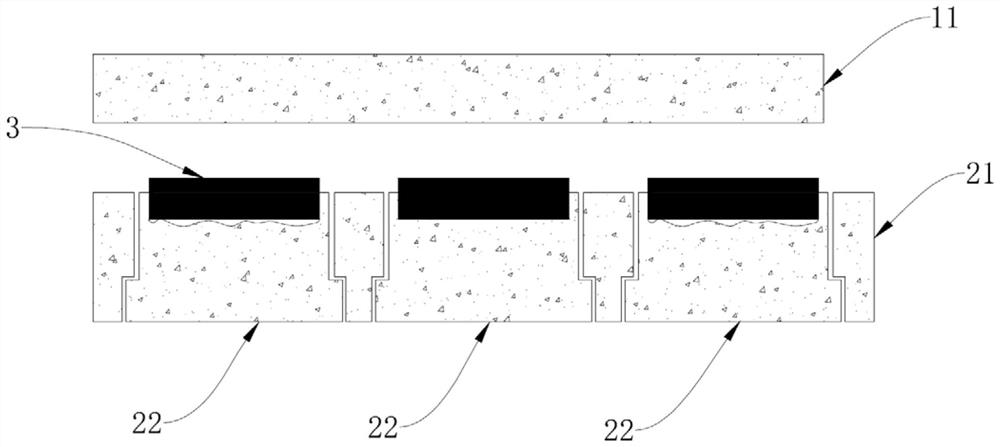

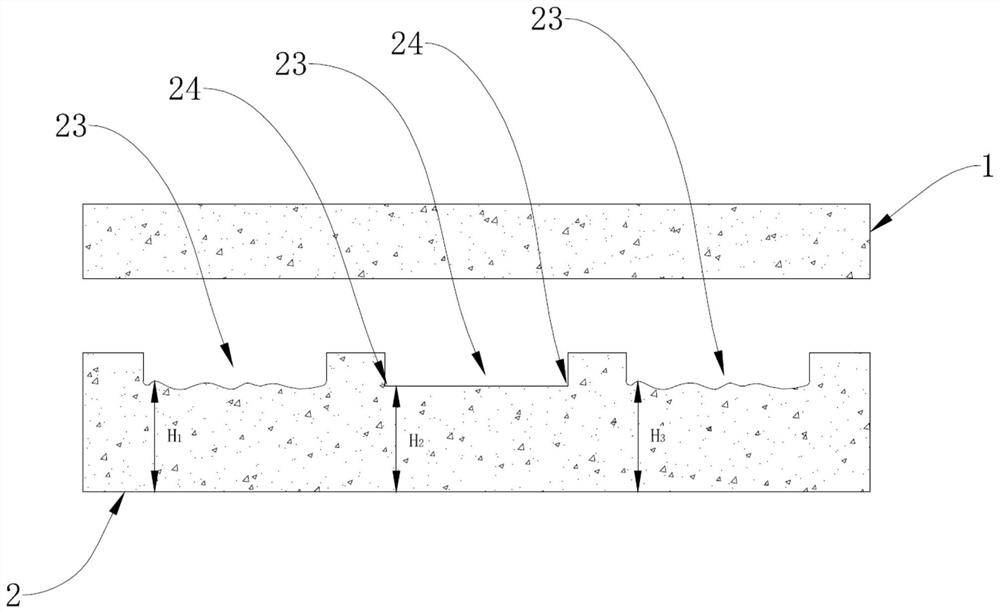

[0033] refer to Figure 2 to Figure 4 , the present embodiment provides a high-precision chamfering processing mold for forming chamfers on the reinforcing plate 3, including an upper mold 1 and a lower mold 2, the upper mold 1 includes a pressed flat plate 11, and the lower mold 2 includes at least one The concave molding cavity 23 is provided with a chamfering area 24 in the molding cavity 23, the molding cavity 23 is used for fixing and positioning the reinforcing plate 3, and the chamfering area 24 is used for pressing and positioning the pressing plate 11 in the molding cavity 23 When the reinforcing plate 3 is formed, chamfers are formed at the edges of the reinforcing plate 3 .

[0034] It should be noted that at least one molding cavity 23 is provided in the form of indentation on the upper surface of the lower mold 2, and a chamfering area 24 is processed in the molding cavity 23 by means of a spherical milling cutter. This chamfering area 24 includes at least one R ...

Embodiment 2

[0042] refer to figure 2 , the present embodiment 2 provides a method applied to high-precision chamfering processing molds in embodiment 1, comprising the following steps:

[0043] S1: Fix several inserts 22 to the lower mold base 21 respectively;

[0044] S2: Put the reinforcing plate 3 in the forming cavity 23 of the insert 22, align the edge of the reinforcing plate 3 to be chamfered with the chamfering area 24 in the forming cavity 23;

[0045] S3: Control the pressing flat plate 11 of the upper mold 1 to press down the reinforcing plate 3 to make the reinforcing plate 3 be chamfered and formed.

[0046] It should be noted that, in step S1, after placing several inserts 22 into the lower mold base 21, the flatness of the bottom surface of the molding cavity 23 is measured and adjusted. If the flatness of the bottom surface of each molding cavity 23 is high, no adjustment is required. If there is a difference in flatness between the molding cavities 23 between different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com