Flame thermal cutting groove head mechanism device

A mechanism device and flame heating technology, applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, inability to adapt to the needs of the thermal cutting industry, and inability to cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

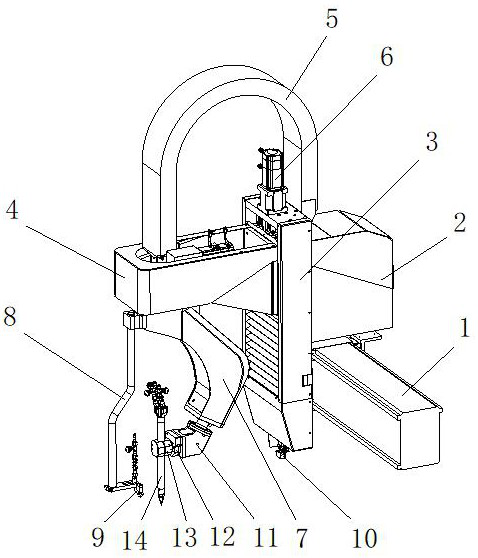

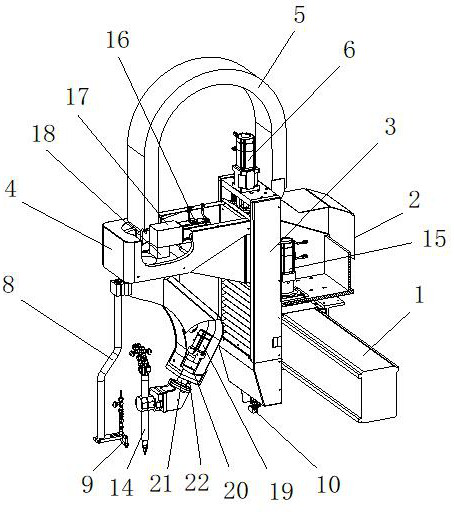

[0031] Specific embodiment one, please refer to Figure 1-2 , a flame thermal cutting bevel head mechanism device, comprising a gantry beam 1, a transverse drive body 2 is installed on the gantry beam 1, and a transverse movement servo motor 15 is arranged inside the transverse drive body 2, and the transverse movement The servo motor 15 can drive the horizontal driving body 2 to reciprocate along the gantry beam 1. The vertical driving body 2 is fixed with an up and down lifting body 3, and the top of the up and down lifting body 3 is fixed with a servo motor 6 for moving up and down. The up and down moving servo motor 6 can drive the up and down lift case 4 to reciprocate in the vertical direction in the up and down lift body 3 through a screw rod, and the up and down lift case 4 is provided with a C-axis servo motor 16, a first-stage precision deceleration motor 17 and two-stage precision deceleration toothed disc 18, and the C-axis servo motor 16 can drive the C-axis rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap