Power-assisted assembly clamping jaw adapting to different types of large and heavy parts

A heavy-duty part, suitable for different technologies, applied in the field of assisting assembly jaws, it can solve problems such as difficulty in meeting actual production requirements and increase the difficulty of product assembly, and achieve the effect of improving assembly flexibility, improving assembly efficiency and reducing rotational speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

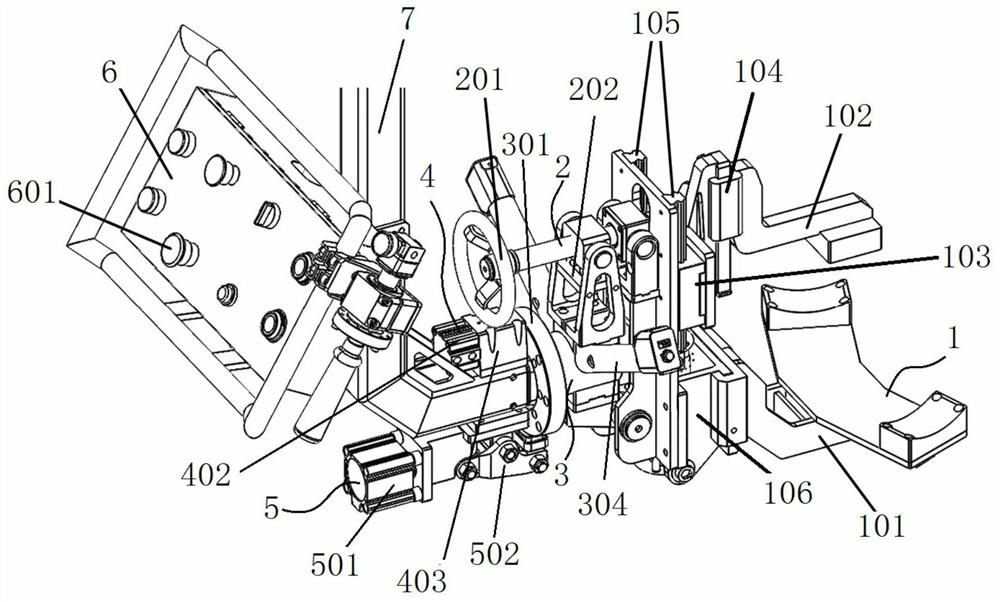

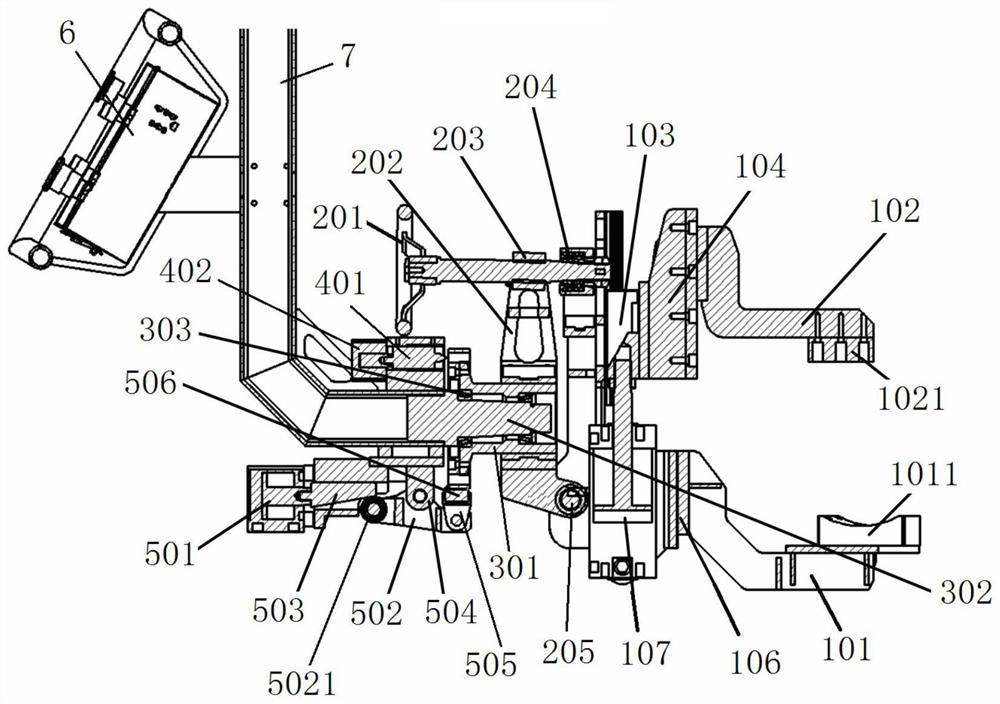

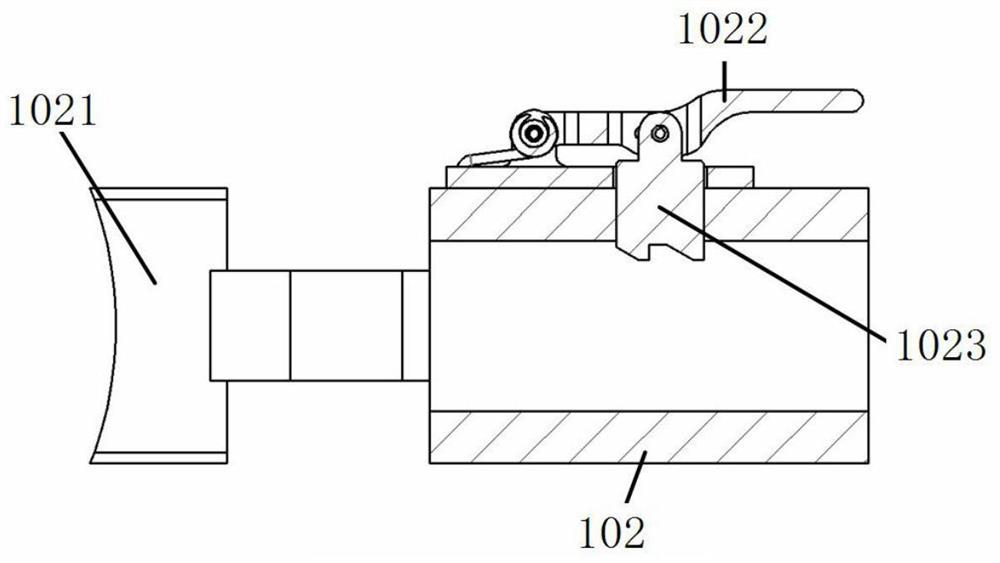

[0028] Such as Figure 1-10 As shown, the present invention includes a support column 7, a rotation mechanism 3, a clamping mechanism 1, a swing mechanism 2, a locking mechanism 4 and a rotation deceleration mechanism 5, wherein the rotation mechanism 3, the locking mechanism 4 and the rotation deceleration mechanism 5 are all arranged on the support column 7, the rotating mechanism 3 is provided with a rotating sleeve 301, and when the rotating sleeve 301 rotates, the rotating speed is reduced by the rotating deceleration mechanism 5, and after the rotation is in place, it is locked by the locking mechanism 4, and the swinging mechanism 2 Including a support frame 202, a handwheel shaft 201 and a screw nut 203, the clamping mechanism 1 is provided with a clamping mounting frame 106, wherein the support frame 202 is fixed on the rotating sleeve 301 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com