Optical fiber color ring printing positioning device and printing device

A fiber positioning and positioning device technology, applied in printing devices, power transmission devices, printing, etc., can solve problems such as difficulties in installing optical fibers, achieve the effects of reducing tremor, extending contact area, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

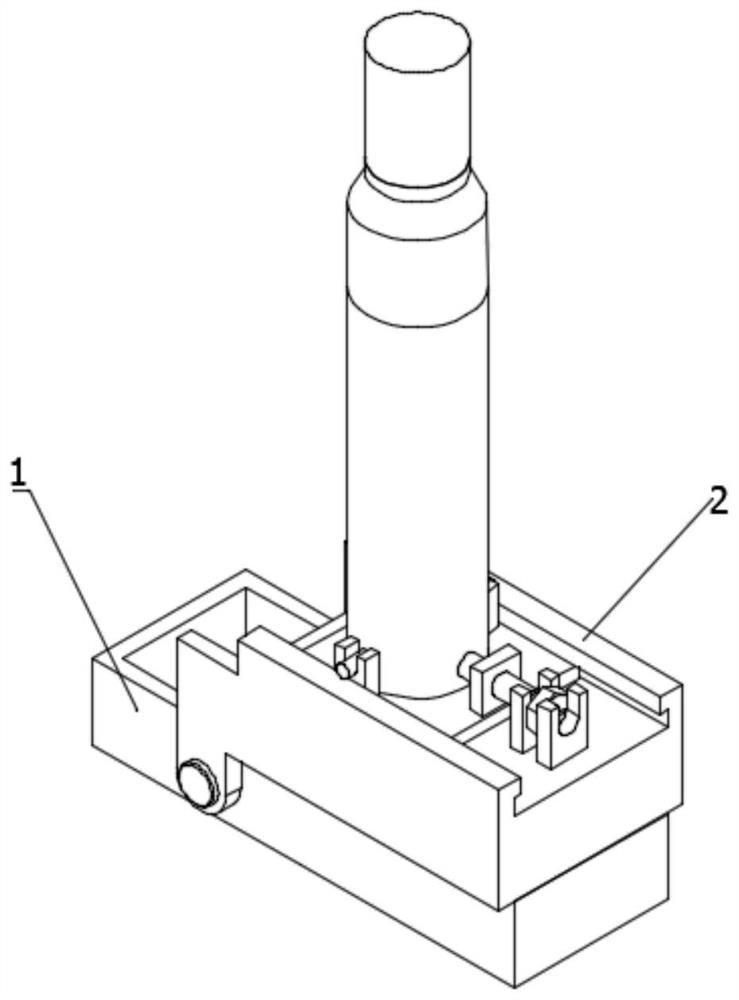

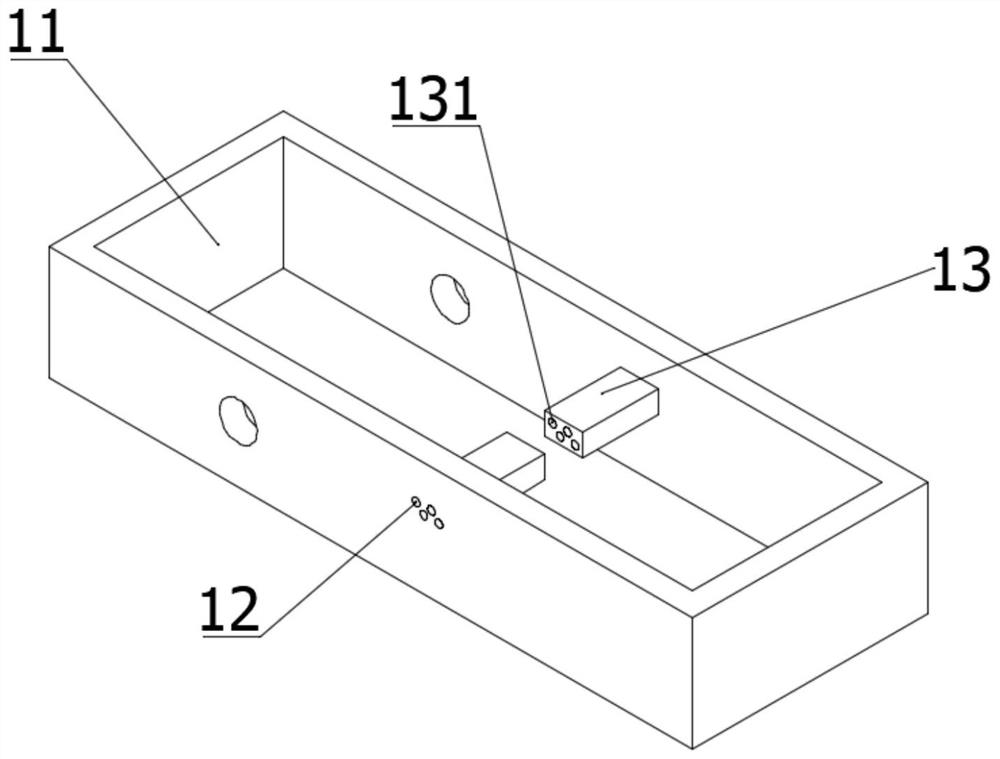

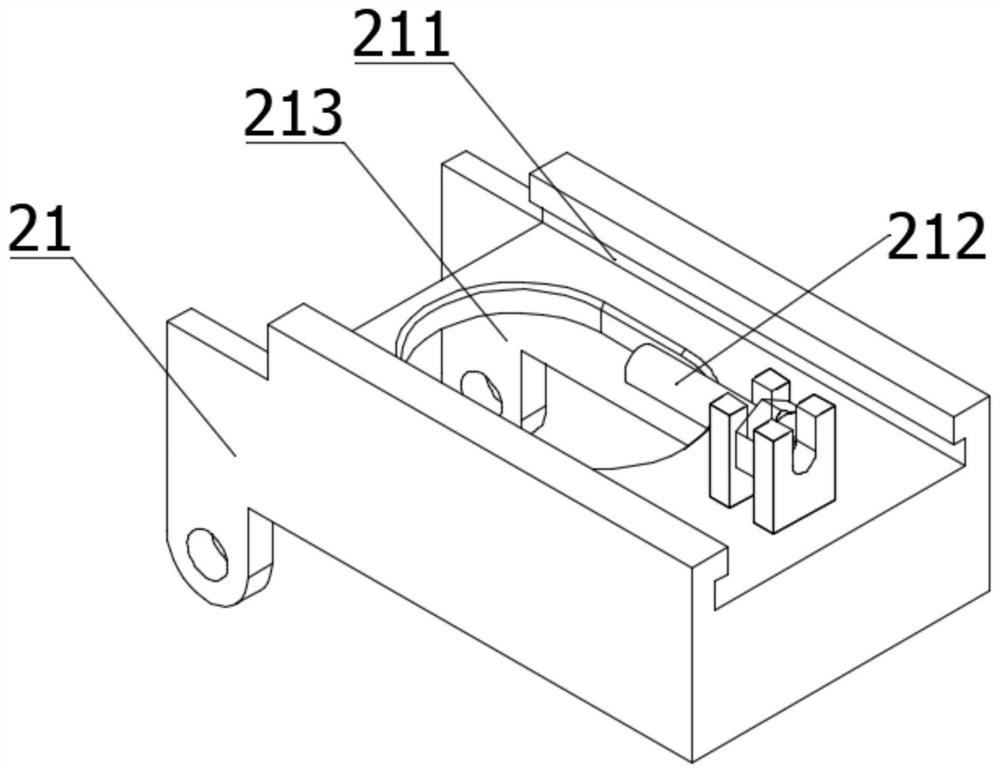

[0054] Such as Figure 1-Figure 2 As shown, the embodiment of the present application provides an optical fiber color ring printing positioning device, including an optical fiber positioning module 1 and a nozzle positioning module 2; the optical fiber positioning module 1 includes a cavity, and two The side wall is provided with a first through hole 12 for the optical fiber to pass through; the nozzle positioning module 2 is hinged to the optical fiber positioning module 1; the nozzle positioning module 2 rotates along the hinged position to realize the sealing of the cavity.

[0055] Preferably, a guide is provided on the side wall where the optical fiber enters the first through hole 12 , and the optical fiber is guided into the first through hole 12 through the guide.

[0056] Preferably, the contact surface between the guide and the pipeline is arc-shaped, and the arc-shaped structure reduces the friction between the surface of the optical fiber and the contact position w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com