Method for producing high-toughness laminar tearing-resistant Z-direction steel with thickness of 50mm

A production method, anti-lamellar tearing technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of lamellar tearing, accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

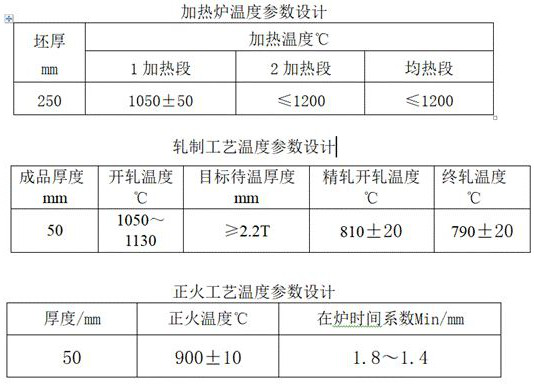

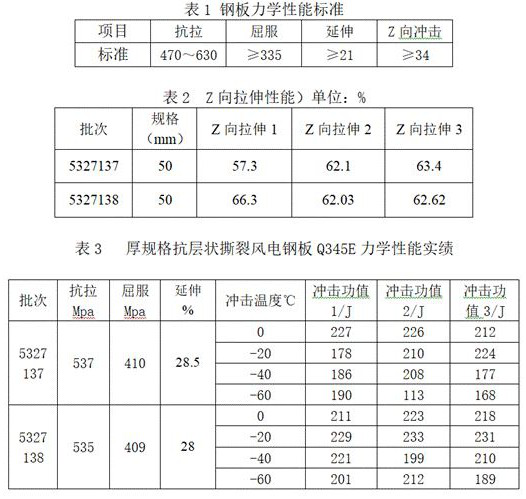

[0018] A production method of high-toughness and anti-layer tearing Z-direction steel with a thickness of 50mm, including two parts: the design of steelmaking composition process parameters and the design of steel rolling process parameters, as follows: 1) The design of steelmaking composition process parameters: thick specification Composition wt.% of wind power steel Z-direction lamellar tear resistance steel: C 0.14, Si 0.36, Mn 1.30, P 0.014, S 0.007, V 0.016, Nb0.018, Als 0.033, Ti 0.022, Ca 0.002; 2) rolled steel Design of process parameters:

[0019] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com