Cylindrical seamless warp-knitted interval protective cover and weaving method thereof

A technology of warp-knitting spacer fabrics and protective covers, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of inability to resist pressure and protect, and achieve the protection of the internal parts of the audio system, which is not easy to collapse and collapse. The effect of large initial modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

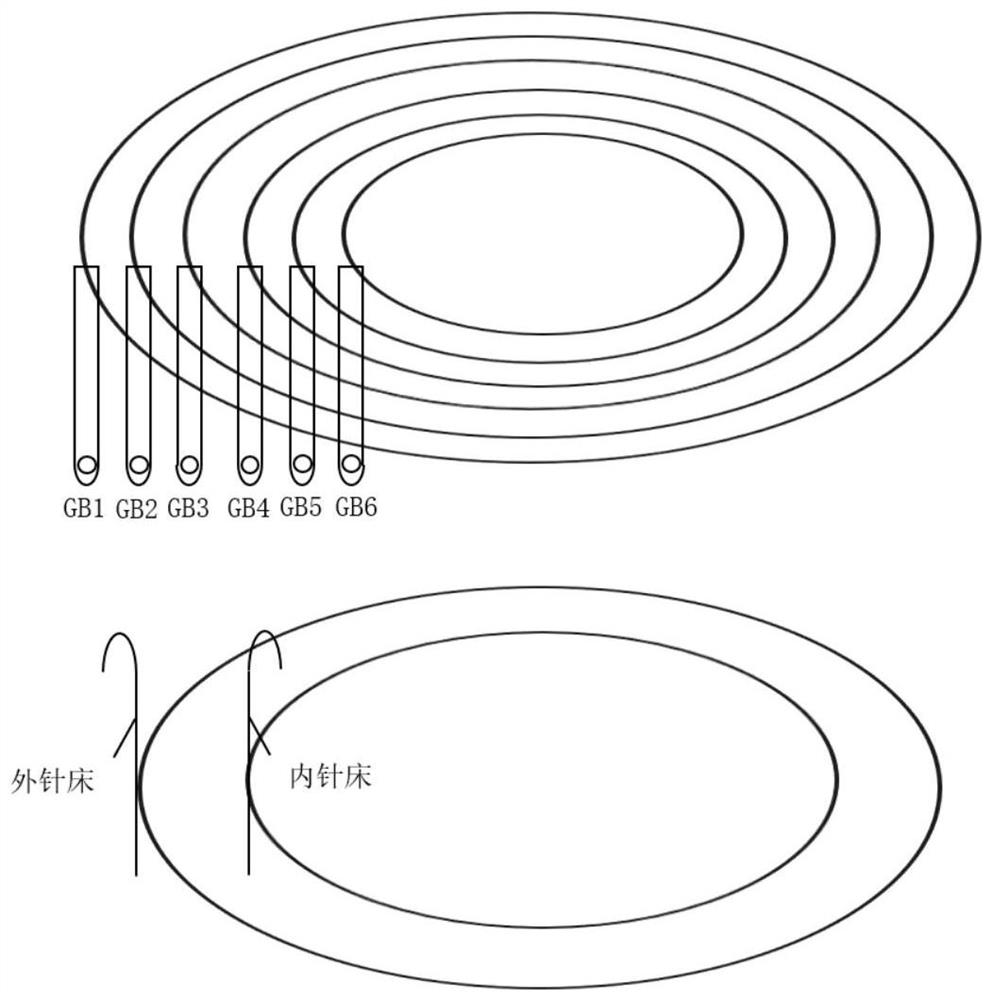

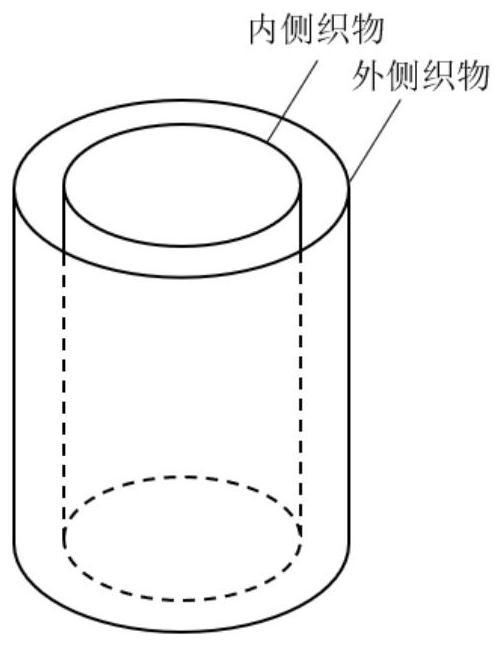

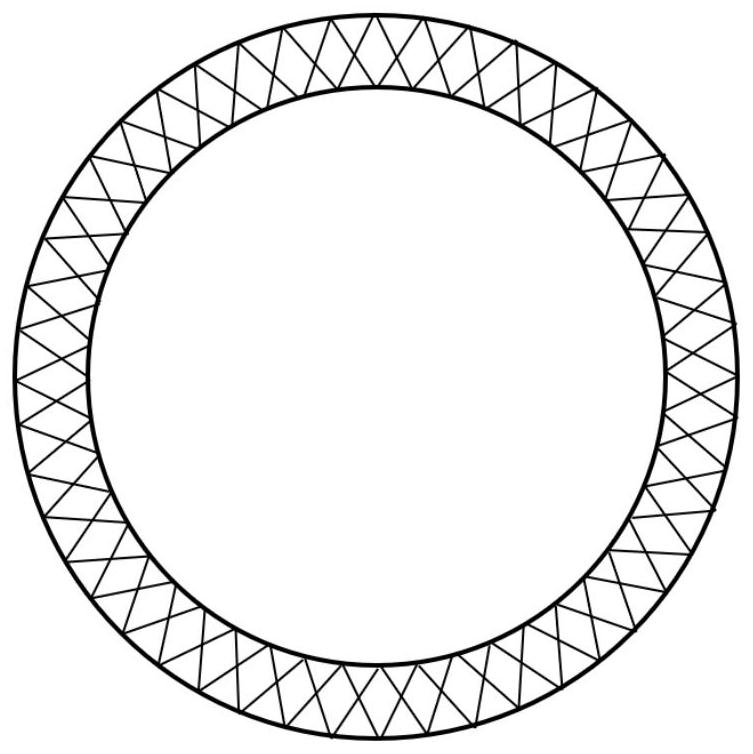

[0047] A kind of weaving method of tubular seamless warp knitting spacer shield, described method is on double-needle cylinder warp knitting machine ( figure 1 The above) weaving; the double-needle cylinder warp knitting machine includes 6 circular bars, and the 6 circular bars are arranged above the knitting needles from the outside to the inside, which are respectively the bars GB1, Bar GB2, bar GB3 and bar GB4, bar GB5, and bar GB6 located above the inner needle cylinder.

[0048] The double-cylinder warp knitting machine is composed of circular guide needles and two needle cylinders. On the basis of the single-cylinder circular warp knitting machine, a circular needle cylinder is added inside the needle cylinder, and the outer and inner needle cylinders are respectively called It is the outer needle cylinder and the inner needle cylinder; the distance between the two needle cylinders is 2-4mm; there are 6 circular combs arranged above the needle cylinder, which are GB1, GB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com