Heating pump assembly and washing device

A heat pump and component technology, which is applied in the direction of washing devices, household cleaning devices, tableware washing machines/rinsing machines, etc., can solve the problems of poor safety, low heating efficiency of heat pumps, and high costs, and achieve power-off protection and improve The effect of heating efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

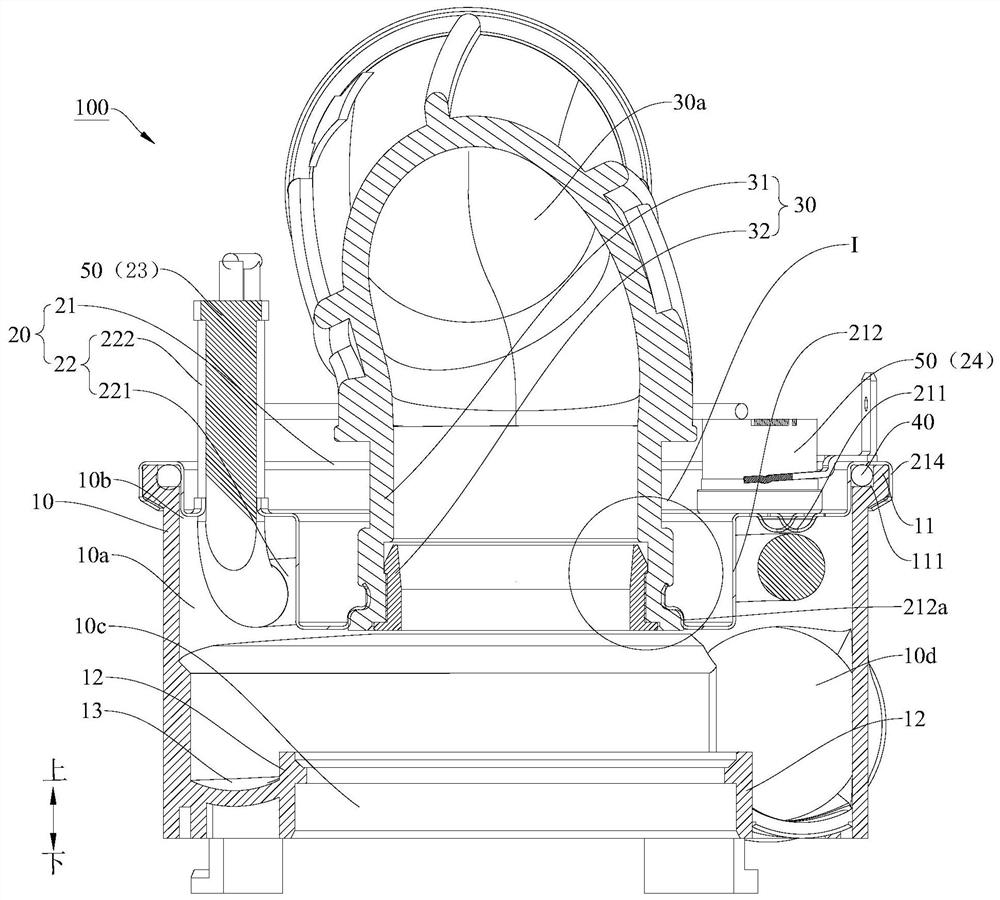

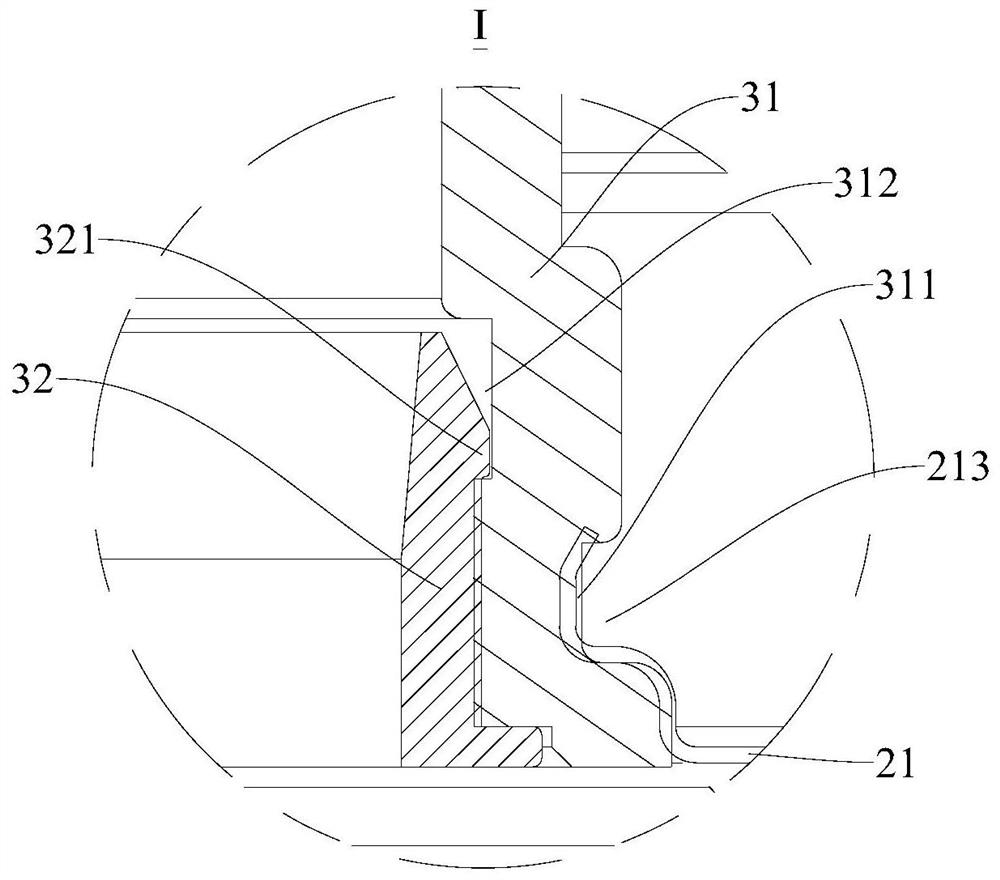

[0086] Such as Figure 1 to Figure 7 As shown, a heat pump assembly 100 includes a pump casing 10 , a pump cover assembly 20 , a water inlet assembly 30 , and a seal 40 .

[0087] The pump casing 10 has a cavity 10a inside, and the pump casing 10 is provided with an installation port 10b communicating with the cavity 10a, an impeller inlet hole 10c and a water outlet 10d.

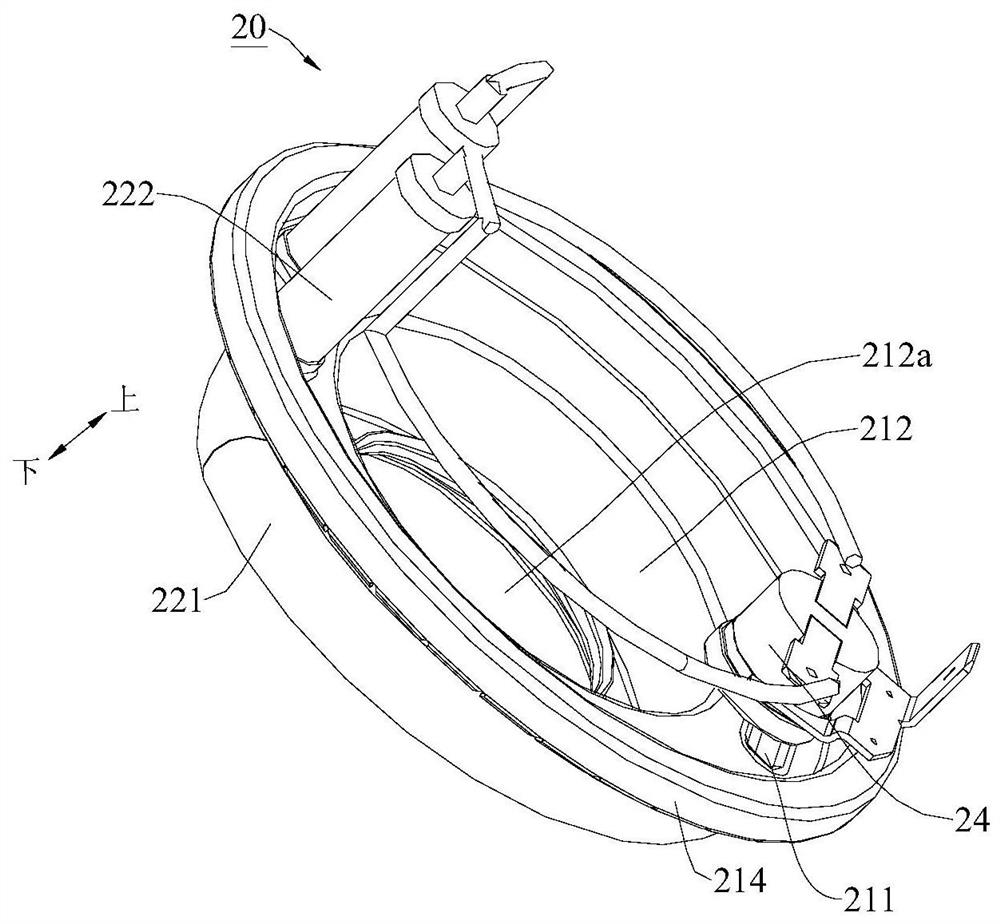

[0088] The pump cover assembly 20 includes a heat conduction cover plate 21 , a heating pipe 22 , an anti-boiling protector 23 , and an anti-boiling protector 24 .

[0089] The heat-conducting cover plate 21 fits on the installation port 10b to seal the installation port 10b. The heating tube 22 is arranged on the heat-conducting cover plate 21 and is located in the cavity 10a. The heating tube 22 includes an arc-shaped heating portion 221 and a connecting portion 222. The heating portion 221 is arc-shaped, and the connecting portion 222 is linear. There are two connecting portions 222 connected to both en...

Embodiment 2

[0096] Such as Figure 8 and Figure 9 As shown, the structure of the heating assembly 100 in the second embodiment is substantially the same as that of the heating assembly 100 in the first embodiment, and the same parts will not be repeated here.

[0097] The difference is that in the second embodiment, the anti-boiling protector 23 and the anti-boiling protector 24 are arranged close to the connection part 222, and the temperature-sensing surfaces of the anti-boiling protector 23 and the anti-boiling protector 24 are attached to the heat conducting The side of the cover plate 21 located outside the cavity 10a.

Embodiment 3

[0099] Such as figure 1 As shown, the structure of the heating assembly 100 in the third embodiment is substantially the same as the structure of the heating assembly 100 in the first embodiment, and the same parts will not be repeated here.

[0100] The difference is that in the third embodiment, the anti-boiling protector 23 is arranged close to the connection part 222 (not shown in the figure), and the temperature-sensing surface of the anti-boiling protector 24 is attached to the heat-conducting cover plate 21, and the anti-boiling The protector 24 is arranged corresponding to the convex portion 211 or the heat conduction block (see figure 1 ).

[0101] A washing device (not shown in the figure) according to an embodiment of the present invention includes the heating assembly 100 as mentioned above.

[0102] According to the washing device of the embodiment of the present invention, the heating assembly 100 can realize the immersion heating of the liquid inside the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com