Fabricated building system

A building system and prefabricated technology, applied in construction, building materials, building components, etc., can solve the problems of insufficient connection strength and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

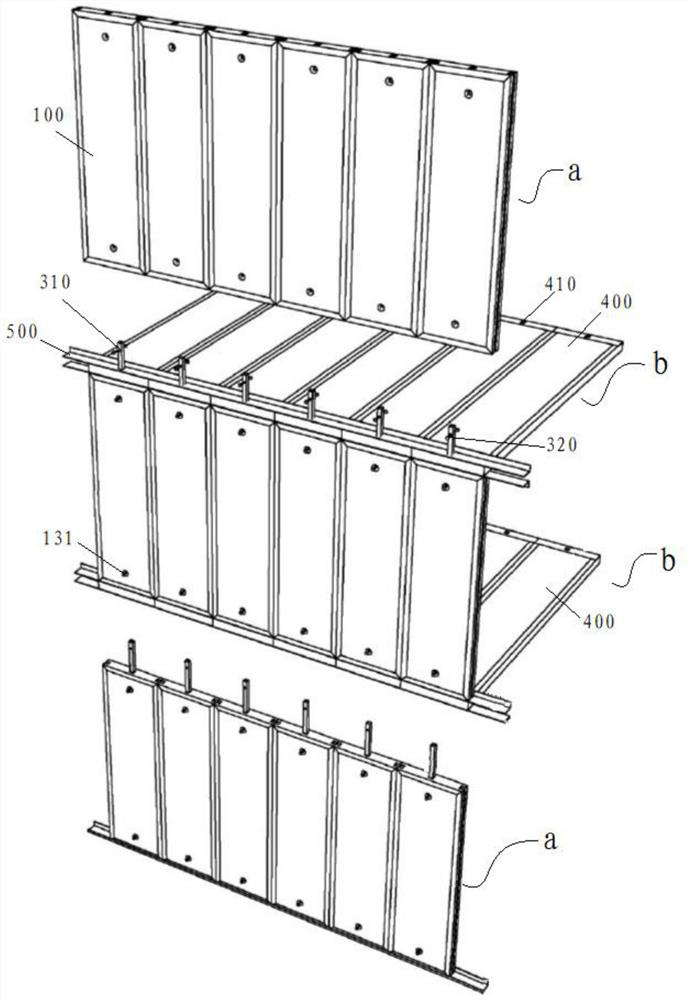

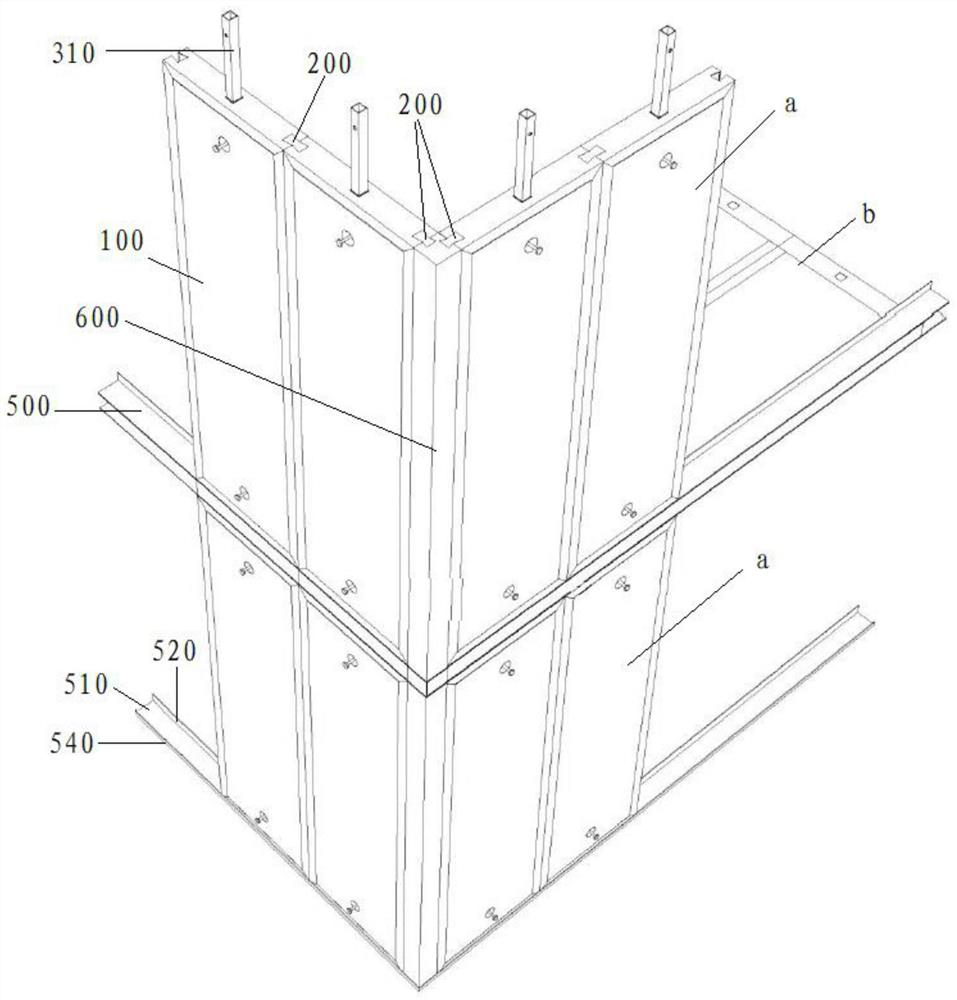

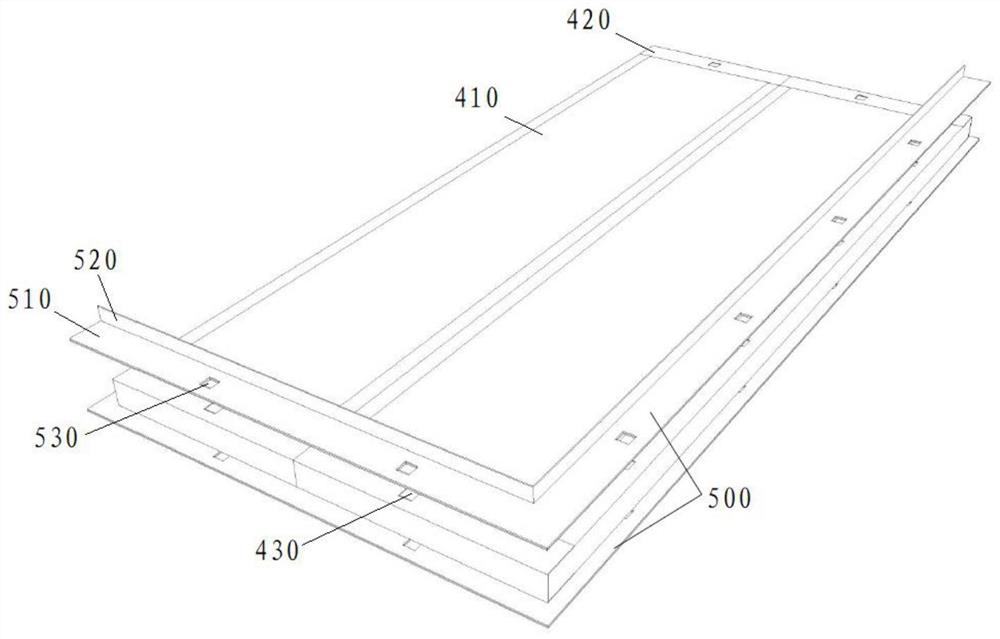

[0052] The embodiment of the present application provides a prefabricated building system, which solves the technical problem of poor overall stability of the prefabricated building in the prior art due to insufficient connection strength between wall panels and floor slabs.

[0053] In order to solve the above technical problems, the general idea of the technical solution provided by the application is as follows:

[0054] The floor layer and the wall layers adjacent to the floor layer up and down are locked together by setting a vertical connecting piece that runs through the floor layer in the middle and can be inserted into and locked at both ends of the upper and lower wall layers. The two ends of the connecting piece can extend to a deeper position in the partition wall, and have a longer overlapping length. After being fixedly connected with the partition wall, it can firmly connect the floor and the upper and lower sides of the floor. Adjacent wallboard layers are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com