A kind of prefabricated building multi-storey roof and its construction technology

A construction technology and assembly technology, applied in the direction of buildings, roofs, building components, etc., can solve problems such as fragile connections, time-consuming and labor-intensive construction, unsafe transportation, etc., and achieve the effect of enhancing strength, increasing overall strength, and avoiding inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 1-7 The application is described in further detail.

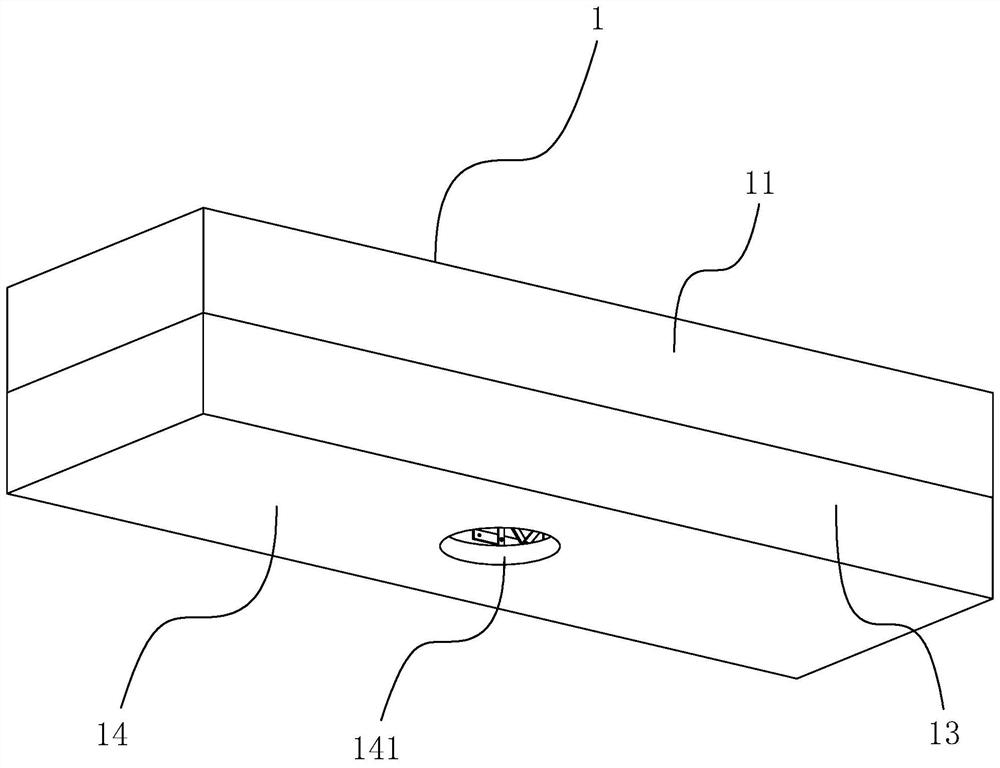

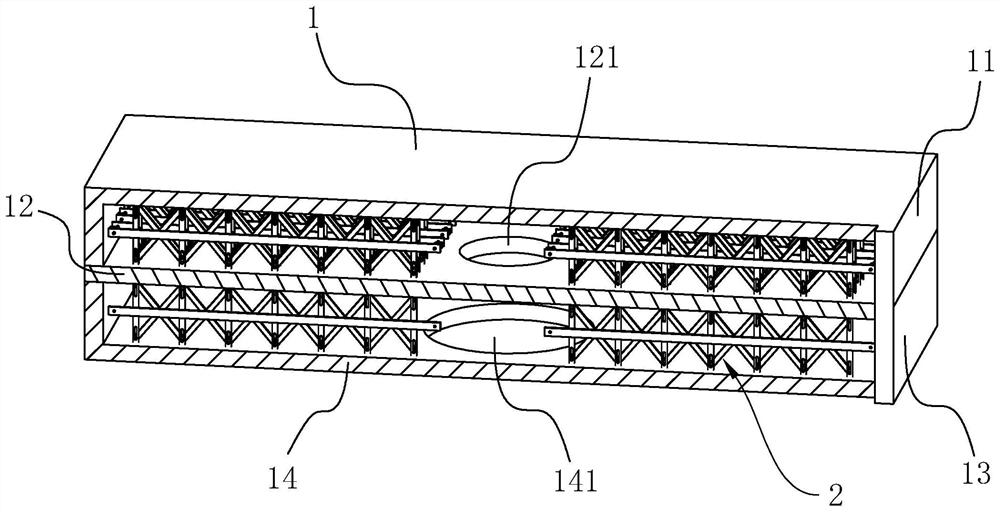

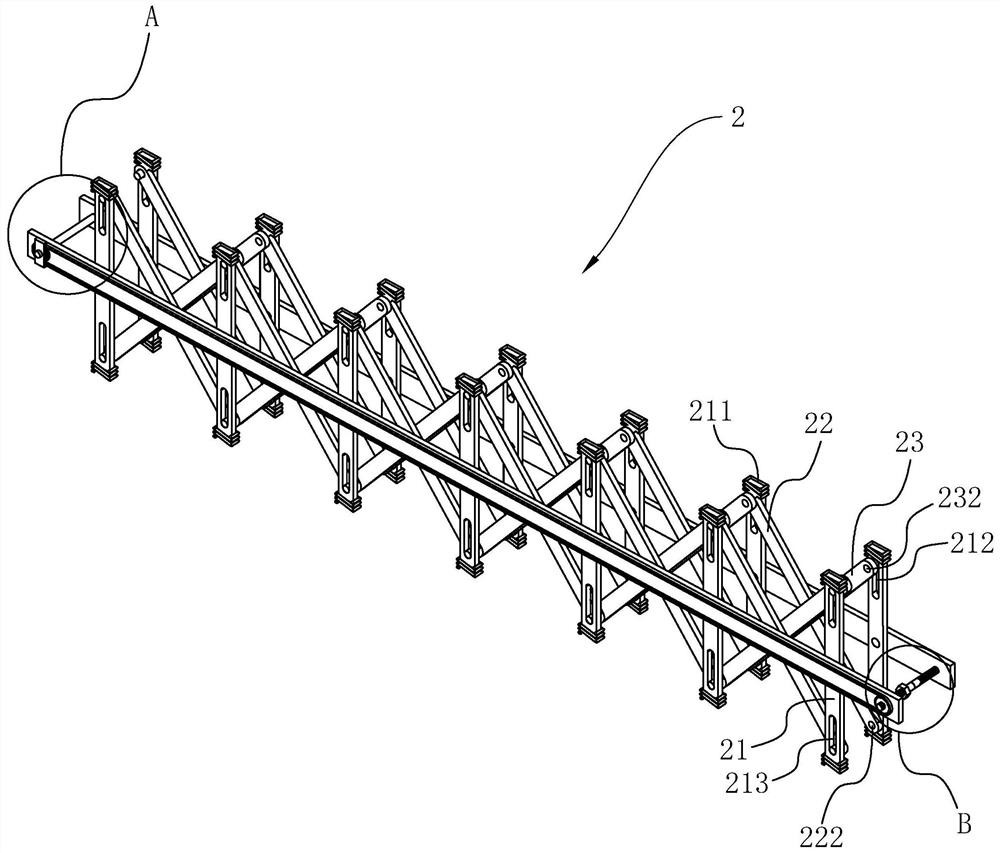

[0046] The embodiment of the present application discloses a multi-layered roof of a prefabricated building, such as figure 1 and figure 2 As shown, it includes the main top layer board 1, the edge of the main top layer board 1 is fixedly connected with the first connection frame 11 arranged perpendicular to the main top layer board 1, and the side of the first connection frame 11 away from the main top layer board 1 is fixedly connected with the first top layer board 12. The first roof panel 12 and the main roof panel 1 are parallel to each other. The first top floor board 12 is fixedly connected with the second connection frame 13 perpendicular to the first top floor board 12 on one side away from the main top floor board 12, and the second connection frame 13 is arranged along the edge of the first top floor board 12, and the second connection frame 13 is away from One side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com