Decoration method for indoor pretreatment

A technology for pre-processing and mounting surfaces, applied in the direction of covering/lining, construction, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

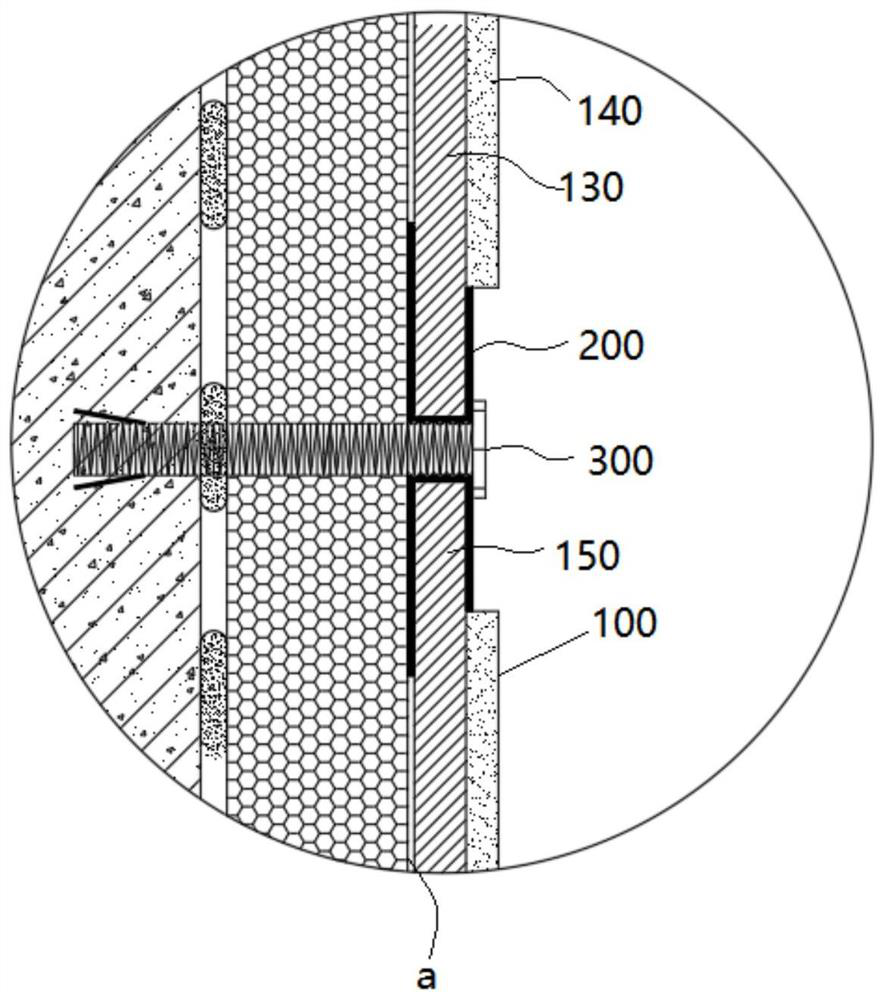

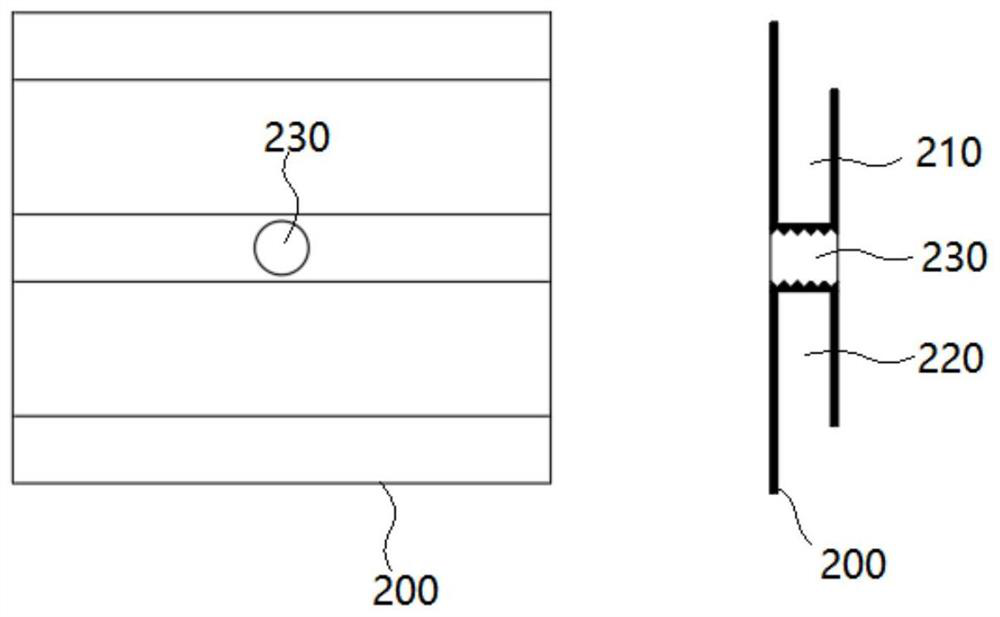

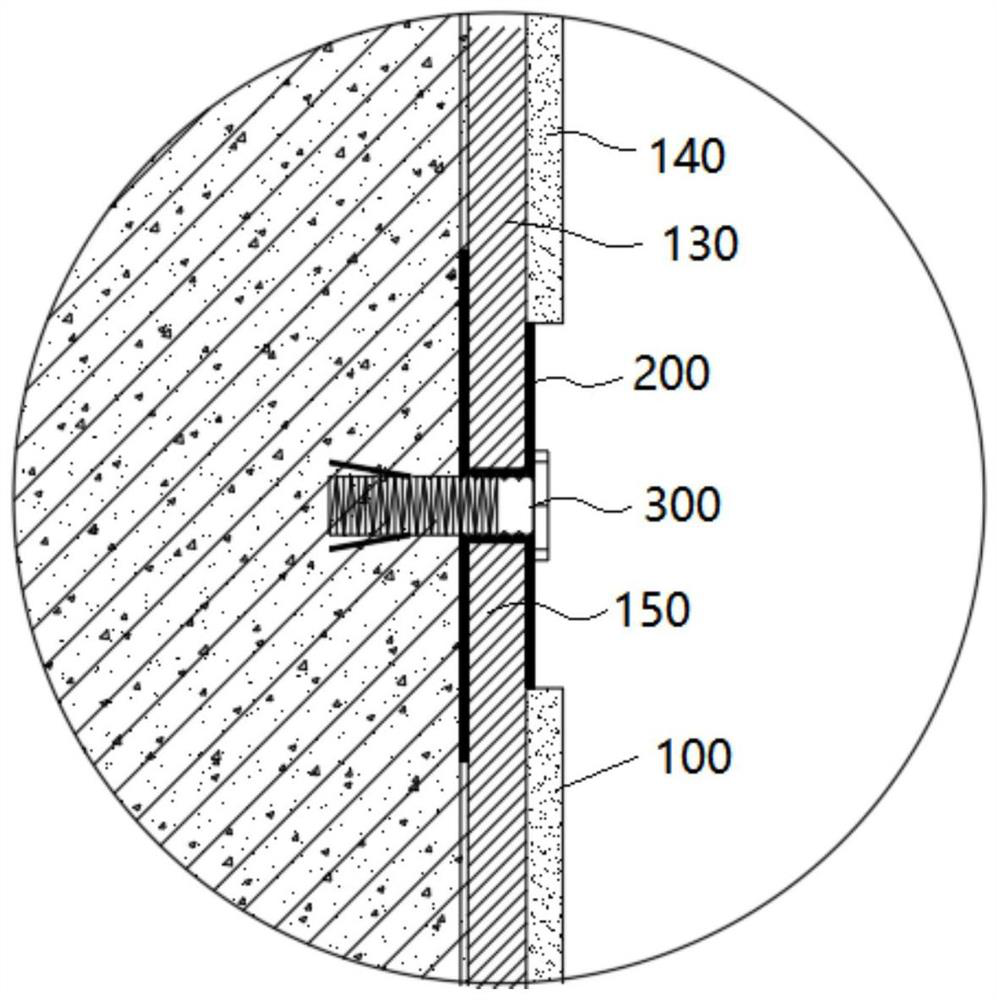

[0052] Refer to attached figure 1 - attached Figure 6 , the present embodiment provides a technical solution: a decoration method for indoor pretreatment includes the following steps:

[0053] Step 1: install the splicing board 100, splice and install the splicing board 100 sequentially on the installation surface, at least one connecting piece 200 is provided on the edge of the splicing board 100, and the connecting piece 200 is used to splice the adjacent splicing boards 100 and the adjacent splicing plate 100 is fixed on the installation surface a, the connecting piece 200 is installed on the installation surface a through the fixing piece 300; the uneven installation surface a is covered by the installation splice plate 100, which is convenient Carry out subsequent decoration processing.

[0054]Step 2: leveling the splicing panel 100, adjusting the distance between the connecting piece 200 and the installation surface a through the fixing piece 300, thereby adjusting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com