Waste glass recovery device on float glass line

A recycling device and waste glass technology, applied in the direction of grain processing, etc., can solve the problems of low melting efficiency of melting furnaces, blockage of cullet glass, and excessive area, so as to save energy and facilitate reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

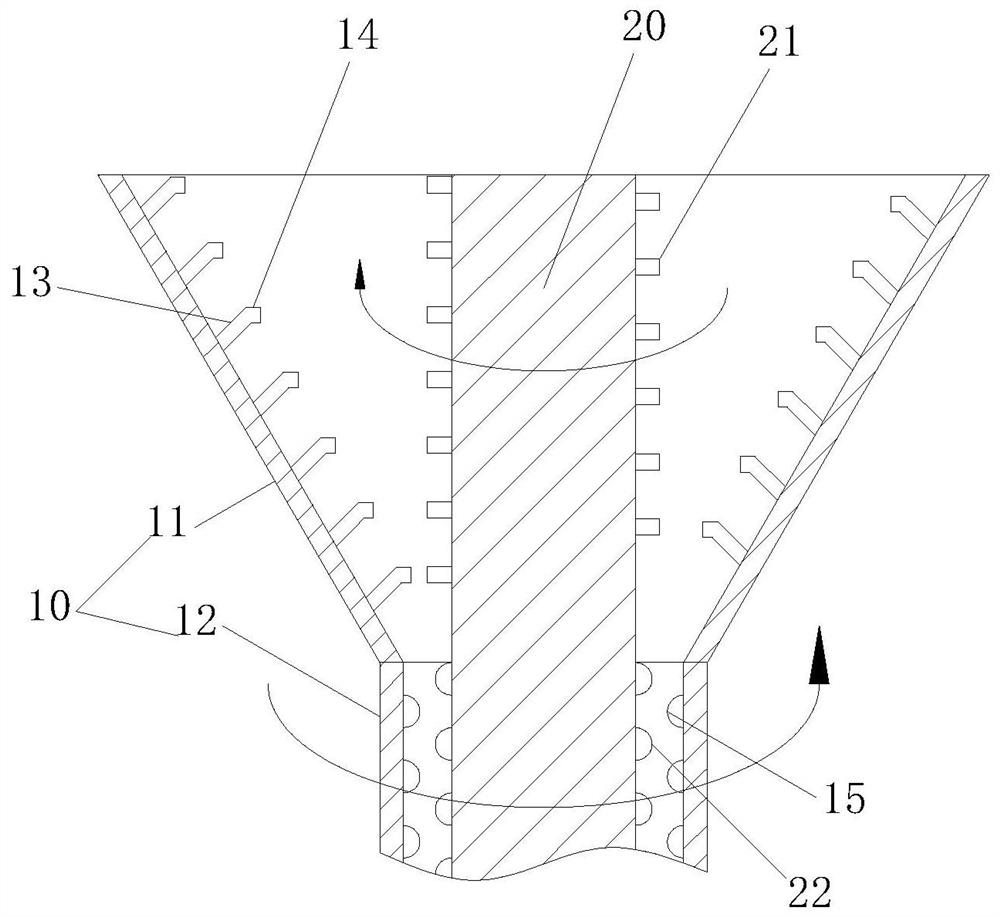

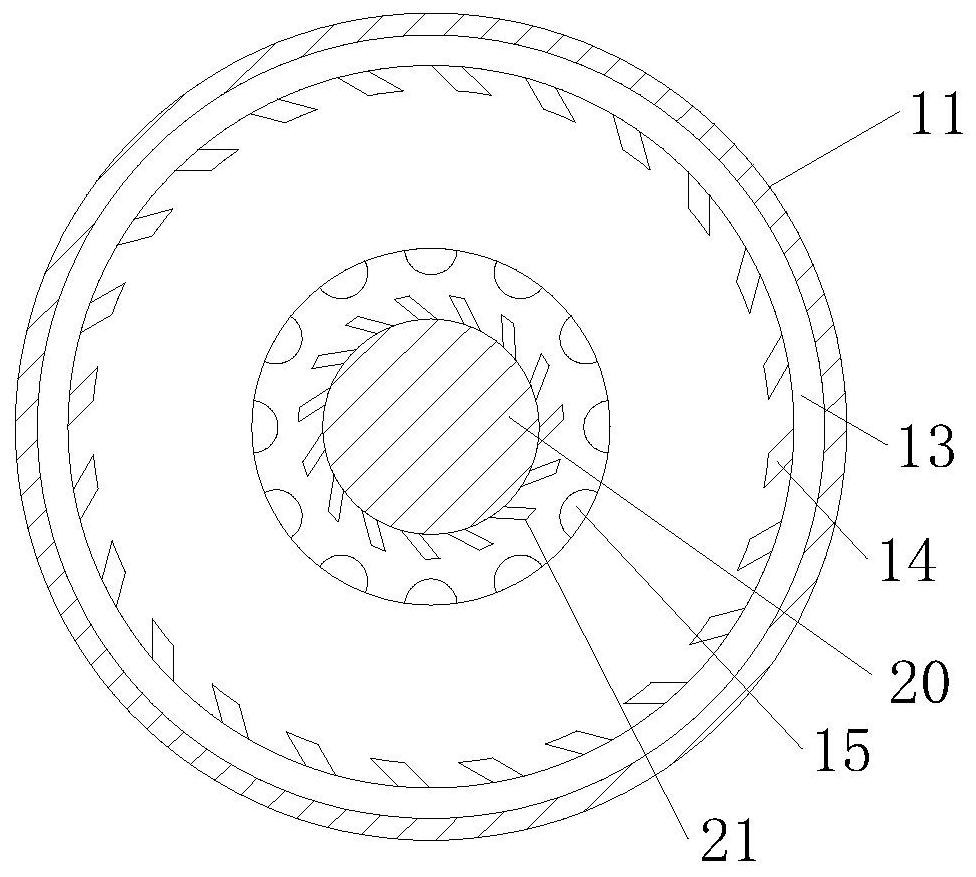

[0019] like Figure 1-2 As shown, the recovery device for waste glass on the float glass line in this embodiment includes a first conveying mechanism, a crushing mechanism and a second conveying mechanism. The waste glass is transported to the crushing mechanism through the first conveying The second conveying mechanism transports to the designated place; the crushing mechanism includes an integrated crusher and a fine crusher, and the integrated crusher includes a funnel-shaped casing 10 and a coaxially arranged crushing column 20, and the rotation direction of the casing 10 is the same as that of the crushing column. In contrast to the crushing column 20, the shell 10 includes a rounded truncated crushing section 11 and a fine crushing section 12. The inner wall of the crushing section 11 is provided with a spiral convex strip 13, and the convex strip 13 is provided with a first crushing section. Protrusion 14, the outer wall of the crushing column 20 is provided with a seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap