Sand screening cylinder automatic cleaning mechanism for sand screening machine

A technology for automatic cleaning and sieving of sand cylinders, applied in the directions of sieve, solid separation, grille, etc., can solve the problems of high cost and damage to the sieve sand cylinder, and achieve the effect of reducing energy consumption, convenient location, and reducing product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

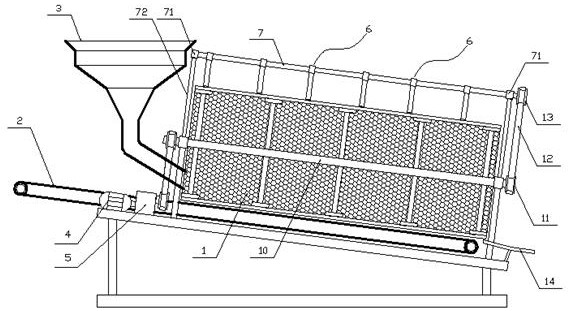

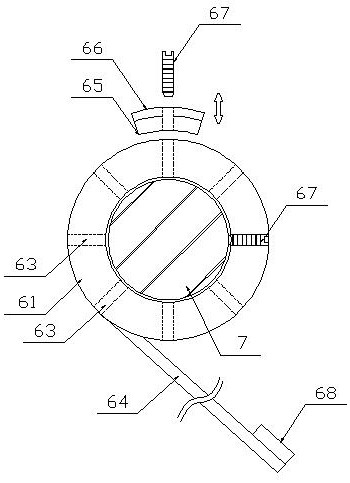

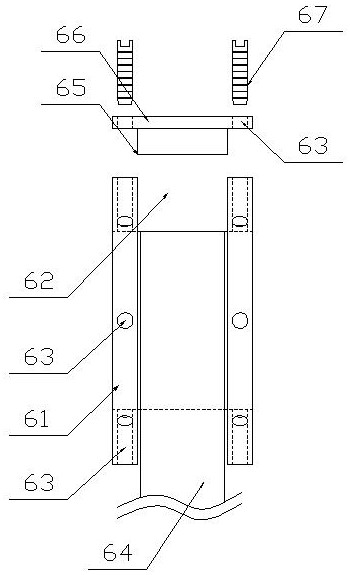

[0028] like figure 1 As shown, the present invention mainly includes a sand screening cylinder 1, a conveyor belt 2 is arranged below the sand screening cylinder 1, and the conveyor belt 2 transports the screened sand to a designated position, and the sand screening cylinder 1 is an inclined structure as a whole. One end is provided with a hopper 3, and the hopper 3 is used to add sand that has not been screened. The sand screening cylinder 1 is also driven to rotate by a reducer 5 driven by a drive motor 4. Specifically, the reducer 5 drives the first connecting shaft 10 through a belt or a chain. Rotate, the first connecting shaft 10 drives the entire sand screening cylinder 1 to rotate, so that the sand and impurities are stirred in the sand screening cylinder 1. During the turning process, the sand leaks from the sand screening cylinder 1 to the conveyor belt 2, and impurities such as stones Screened out through the material guide plate 14; in order to play a cleaning effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com