Method for reducing hardening of raw ore vibrating screen

A vibrating screen, raw ore technology, applied in chemical instruments and methods, sieves, solid separation and other directions, can solve the problems of high raw ore sludge powder content, high labor intensity, increase blast furnace pressure difference, etc. Reduce labor intensity and reduce the effect of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

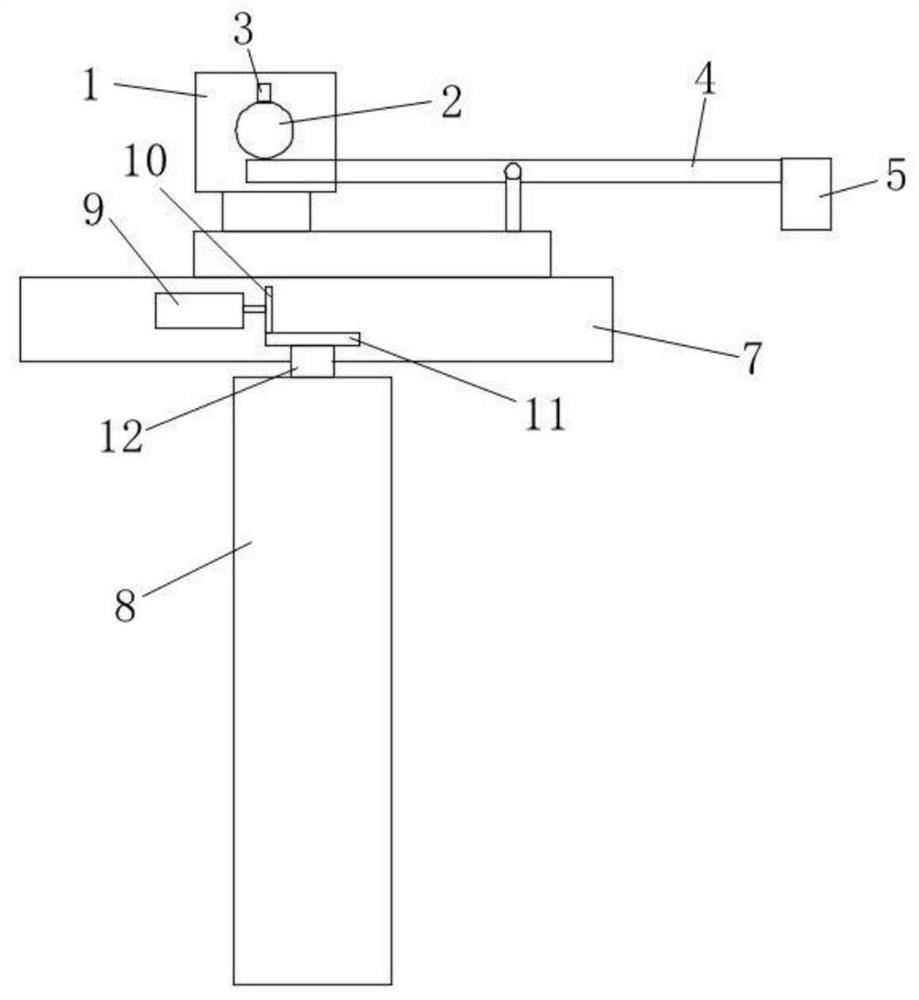

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

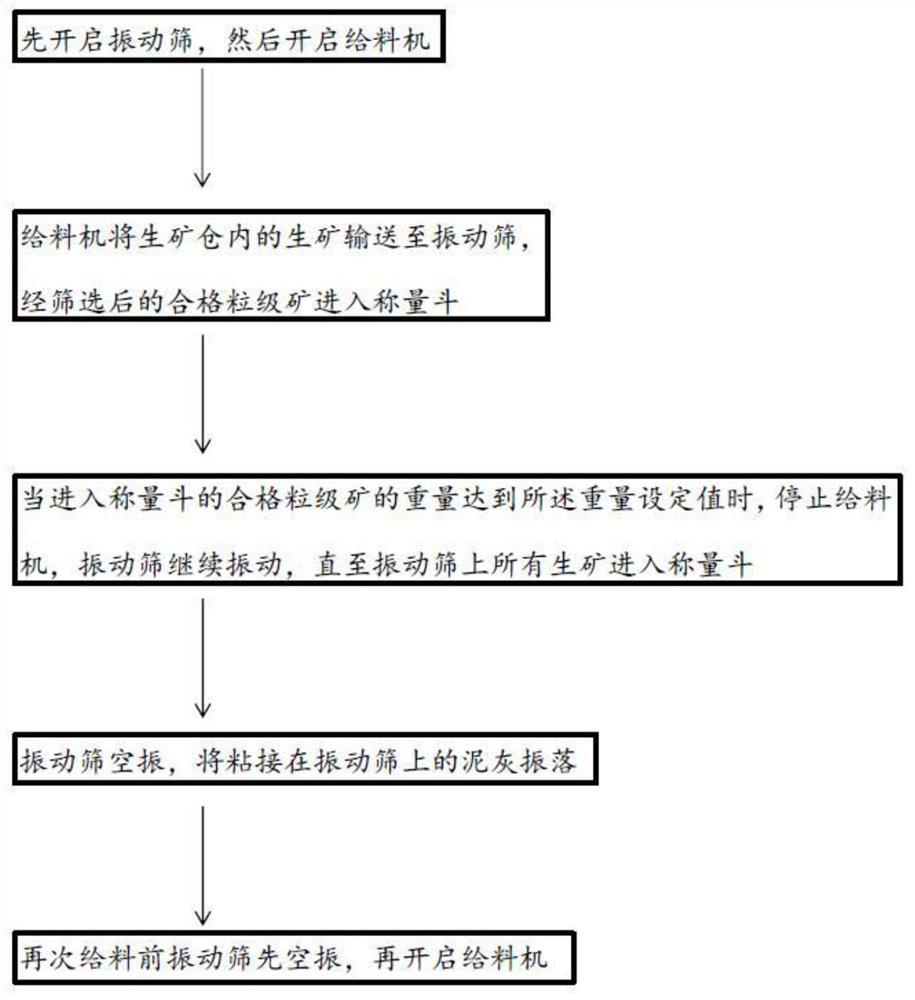

[0035] The screening process of the raw ore in the prior art is that the feeder transports the raw ore in the raw ore bin to the vibrating screen, and the screen of the vibrating screen screens out the fine-grained ore and mud powder in a vibrating state. The raw ore left on the screen is the qualified ore, and then the qualified ore enters the weighing hopper. When the weight in the weighing hopper reaches the set weight, the feeder and the vibrating screen stop immediately to achieve weighing. bucket accurate weighing. However, because the raw ore is unprocessed, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com