Resin dissolving device capable of increasing dissolving rate and automatically manufacturing precoated sand

A technology of dissolution rate and dissolution device, which is applied in the field of coated sand, can solve problems such as low work efficiency, low resin dissolution rate, and insufficient automation, and achieve the effects of improving work efficiency, accelerating resin dissolution rate, and automation function work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

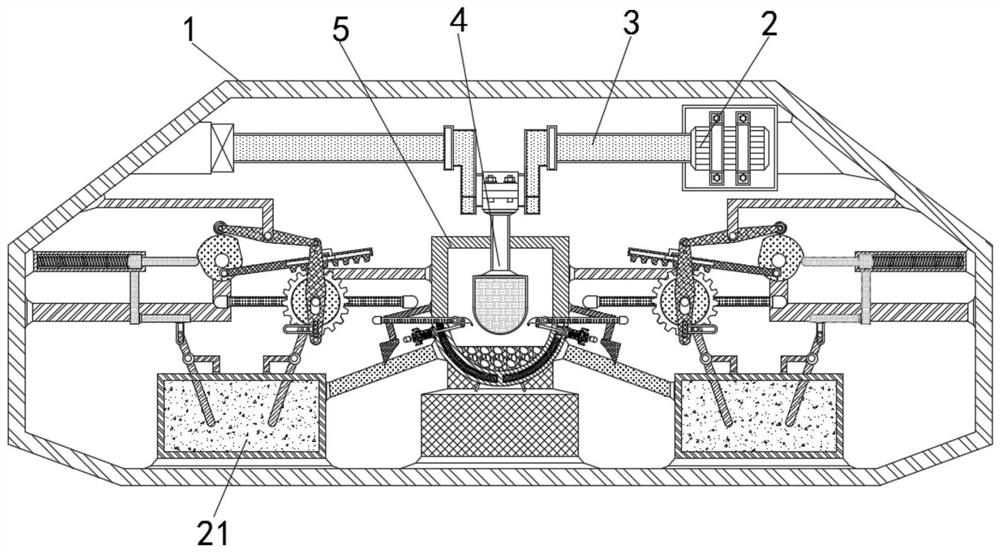

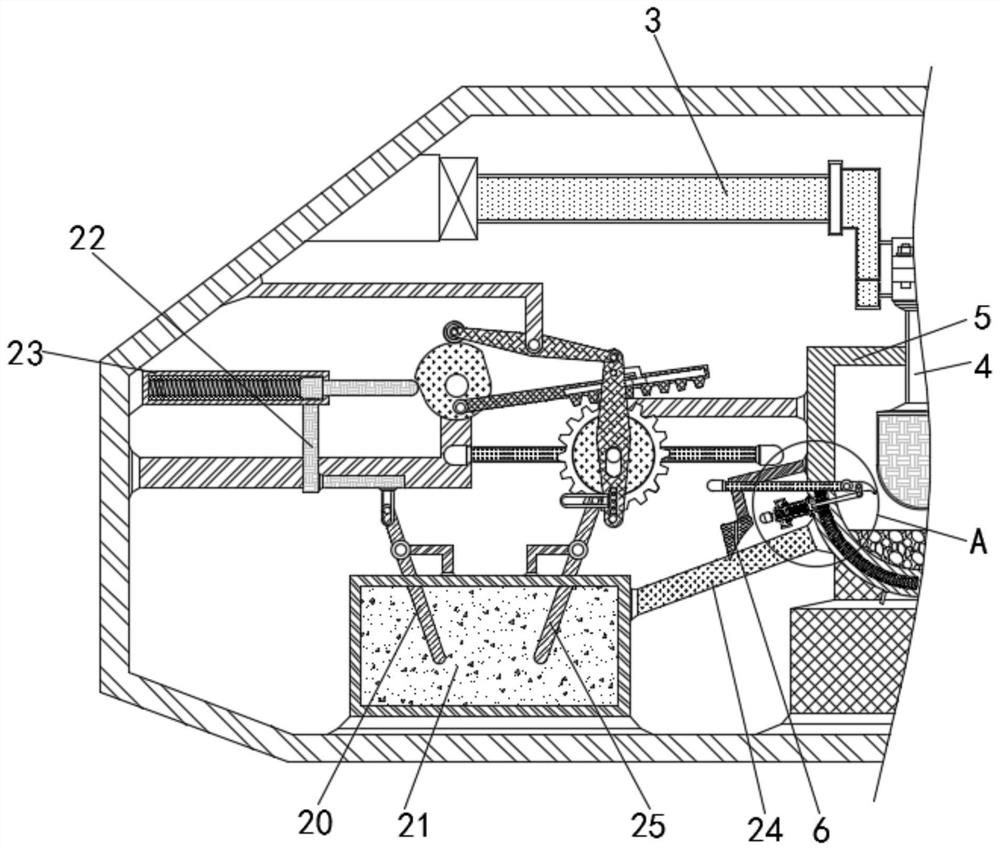

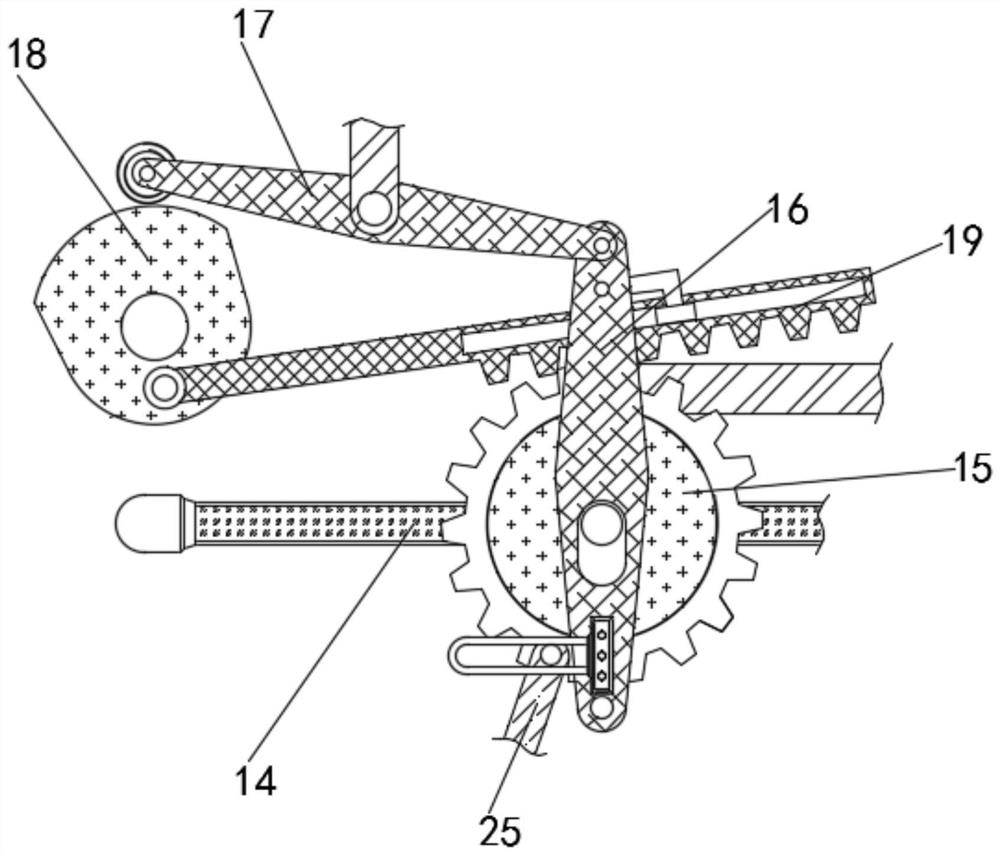

[0024] See Figure 1-5 A resin dissolution device that can accelerate the dissolution rate and automate the production of the film sand, including the housing 1, and the inner side of the housing 1 is fixedly connected to the motor assembly 2, and the left side of the motor assembly 2 is rotated with a first rotational shaft 3, The intermediate position of the first rotating shaft 3 is rotated to be connected to a gravity hammer 4, and a grinding chamber 5 is provided on the lower side of the gravity hammer 4, and the abrasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com