Patents

Literature

46results about How to "Preparation automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

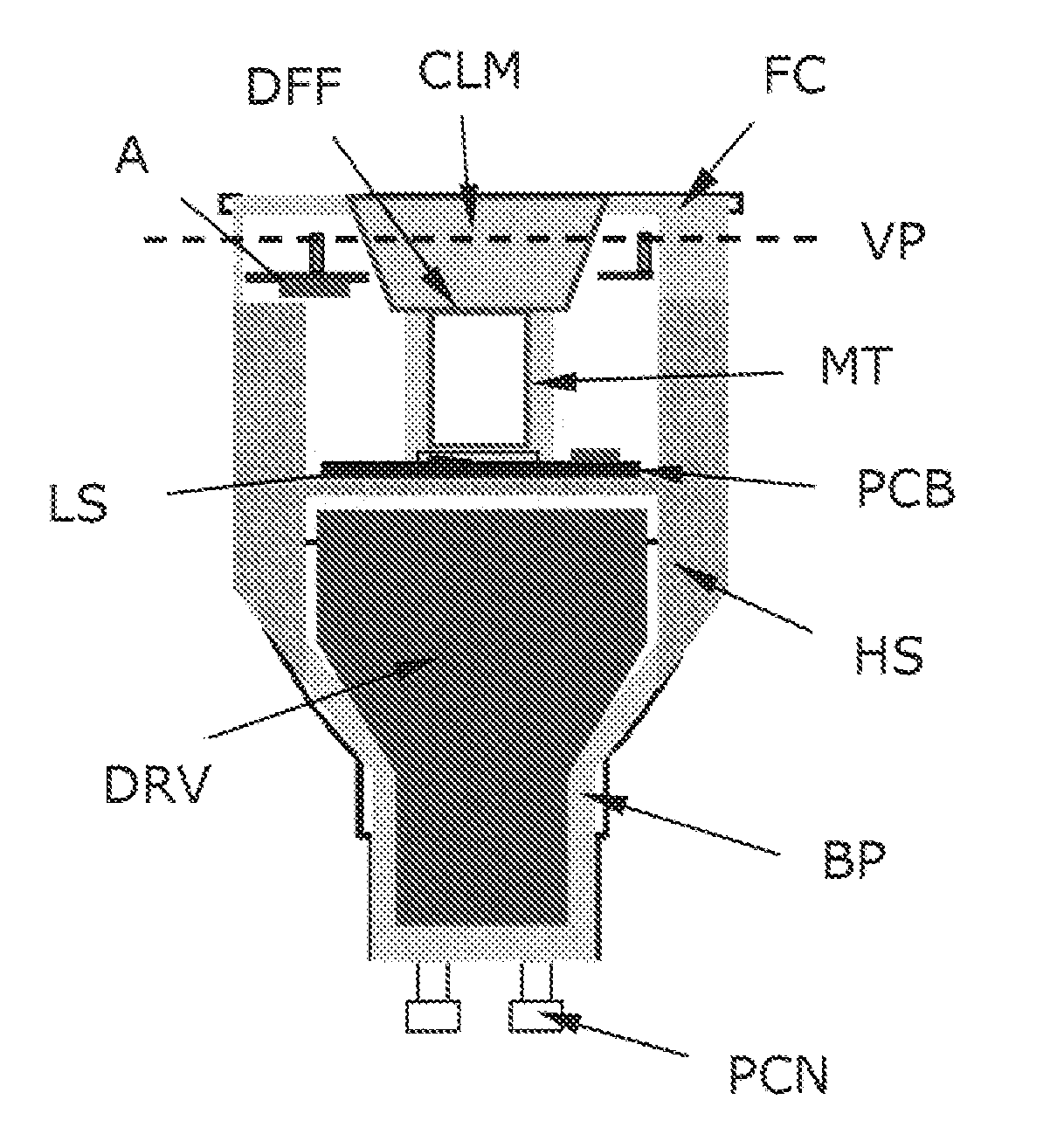

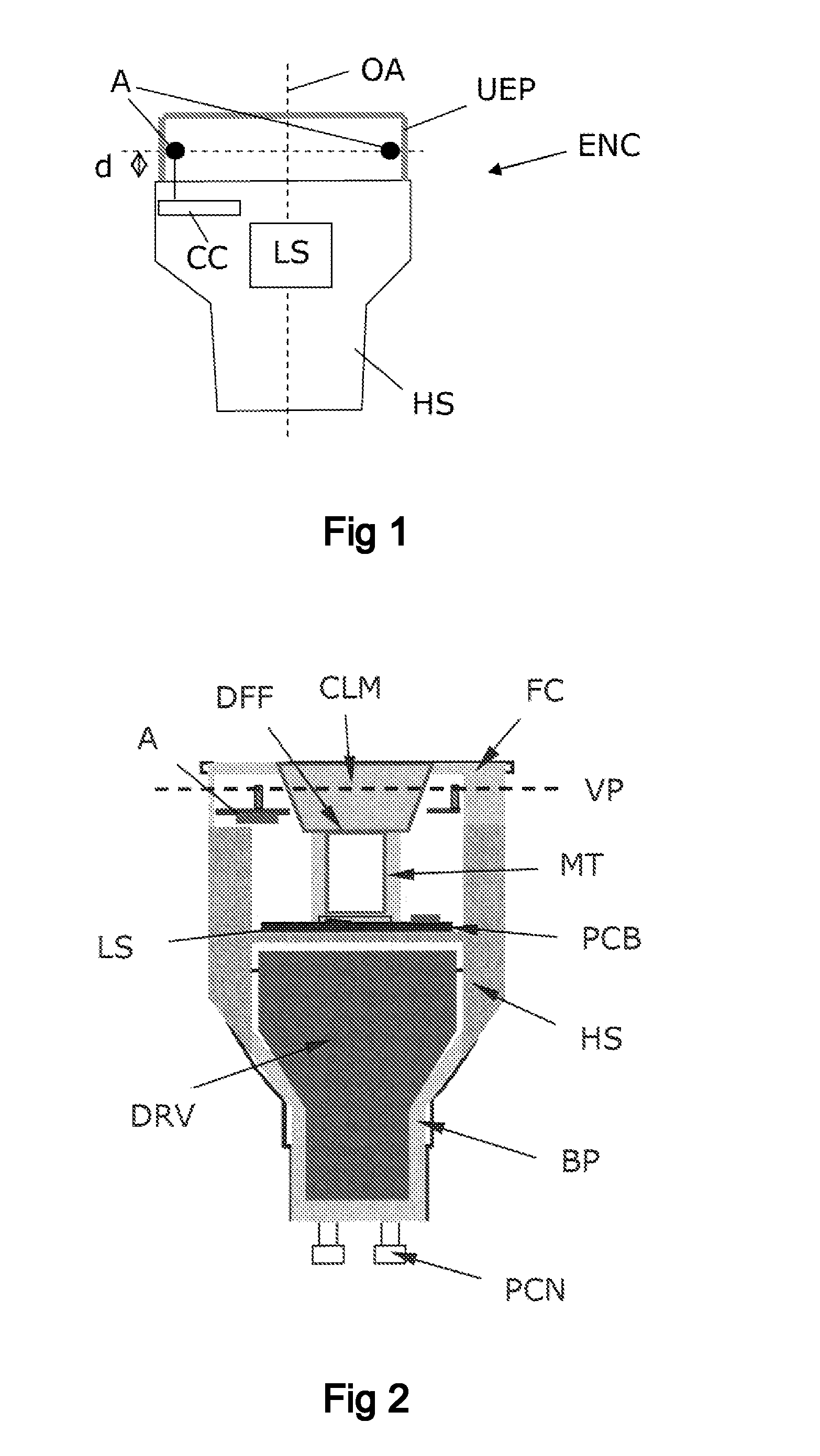

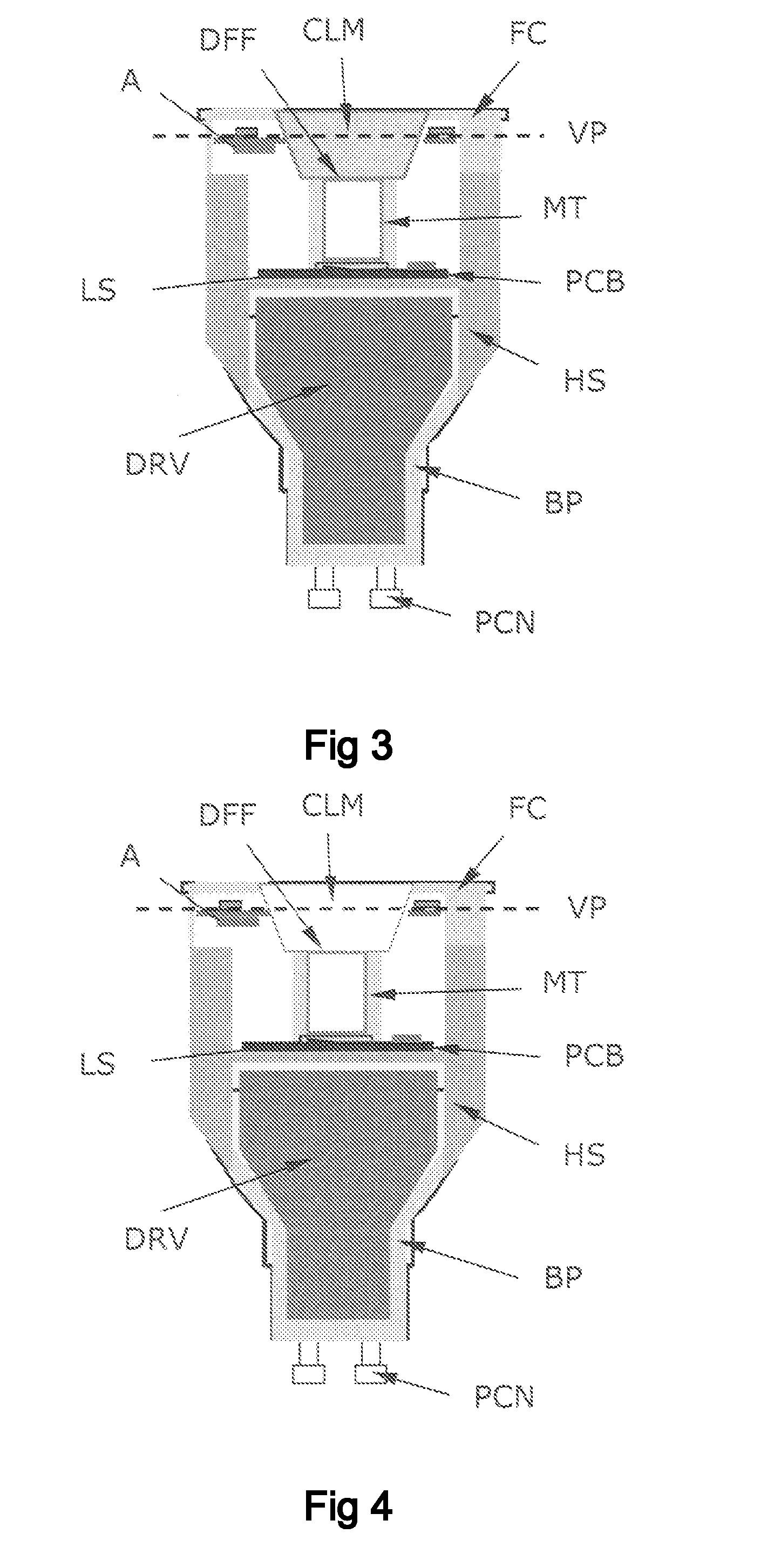

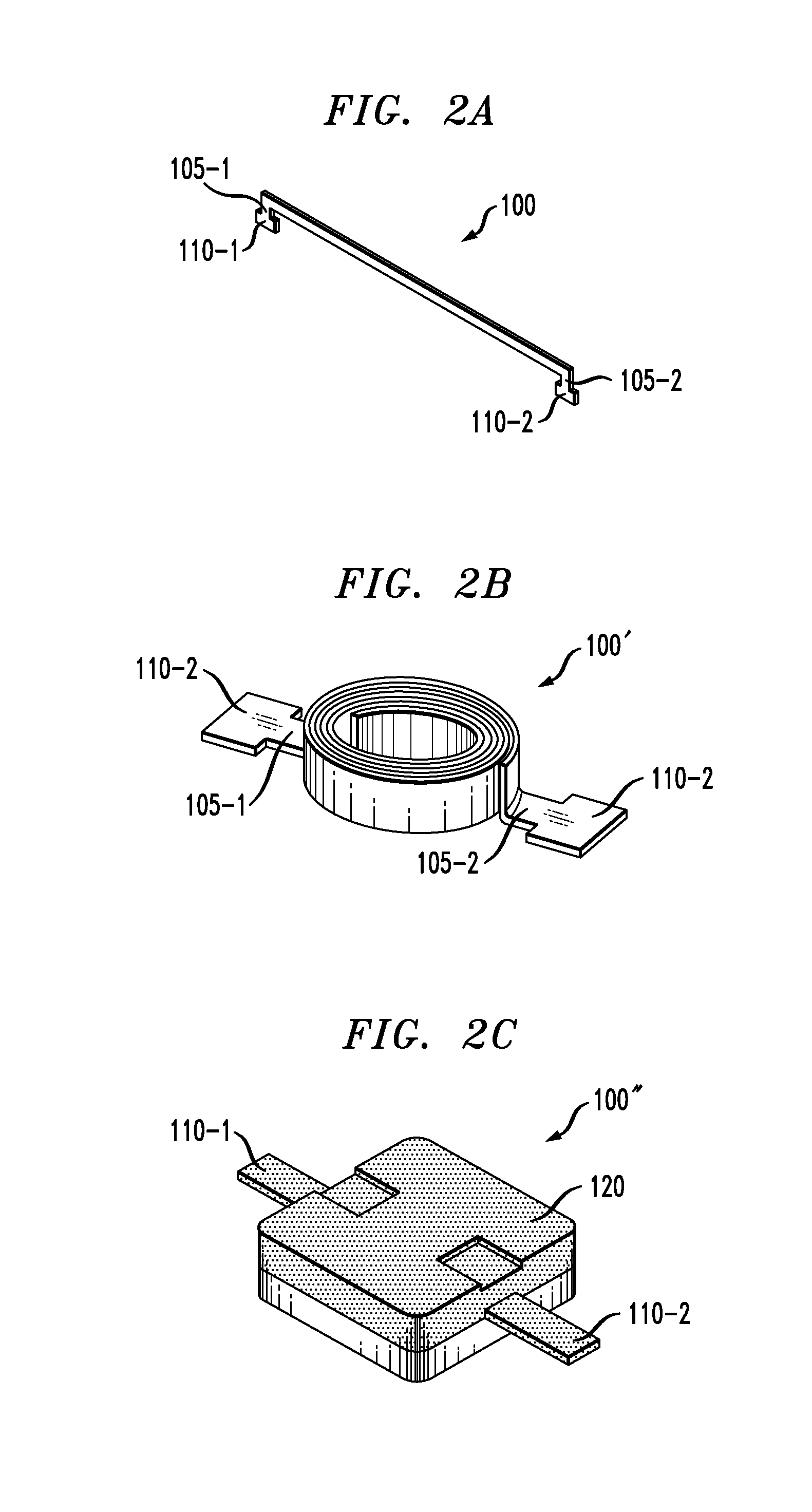

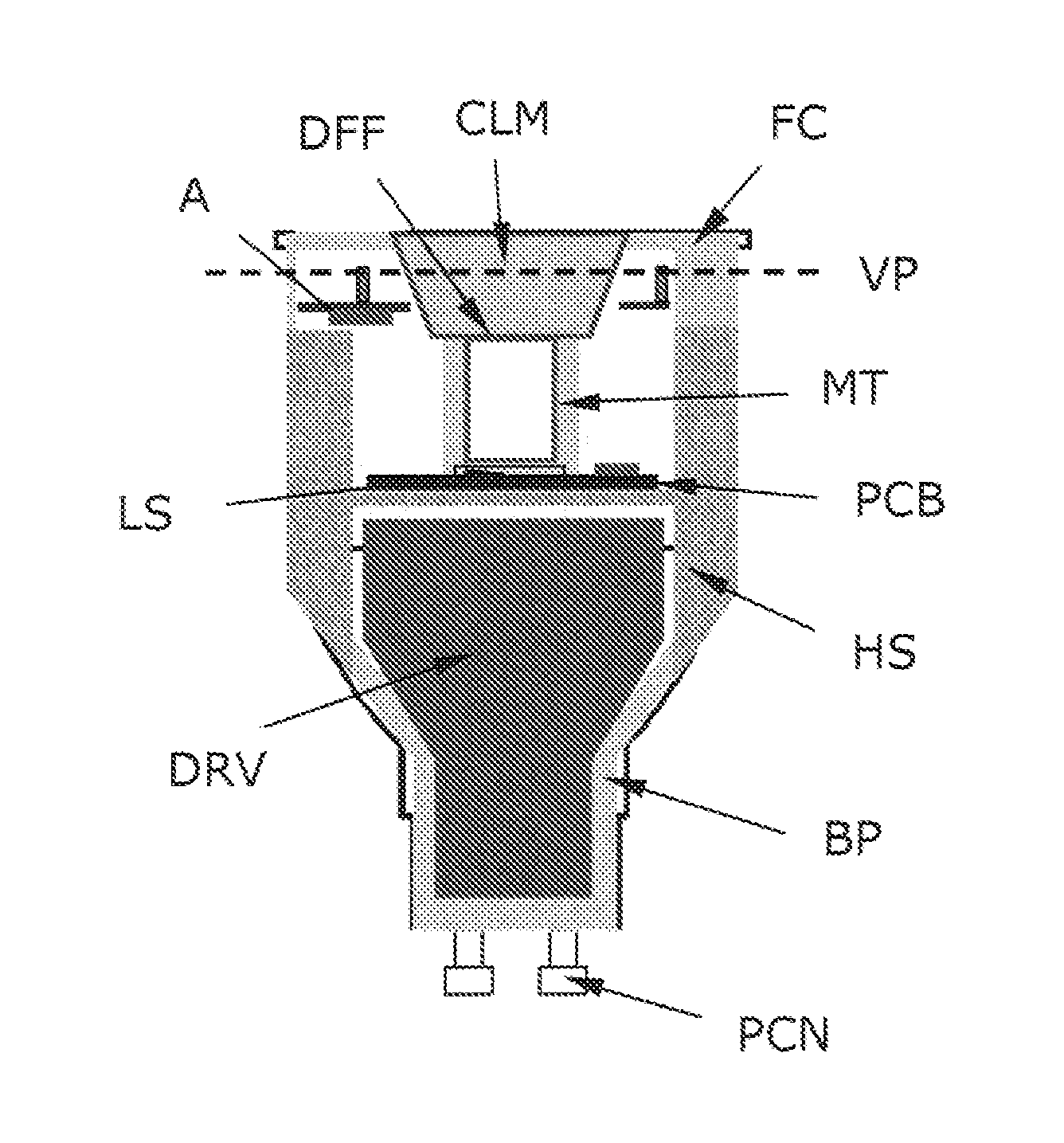

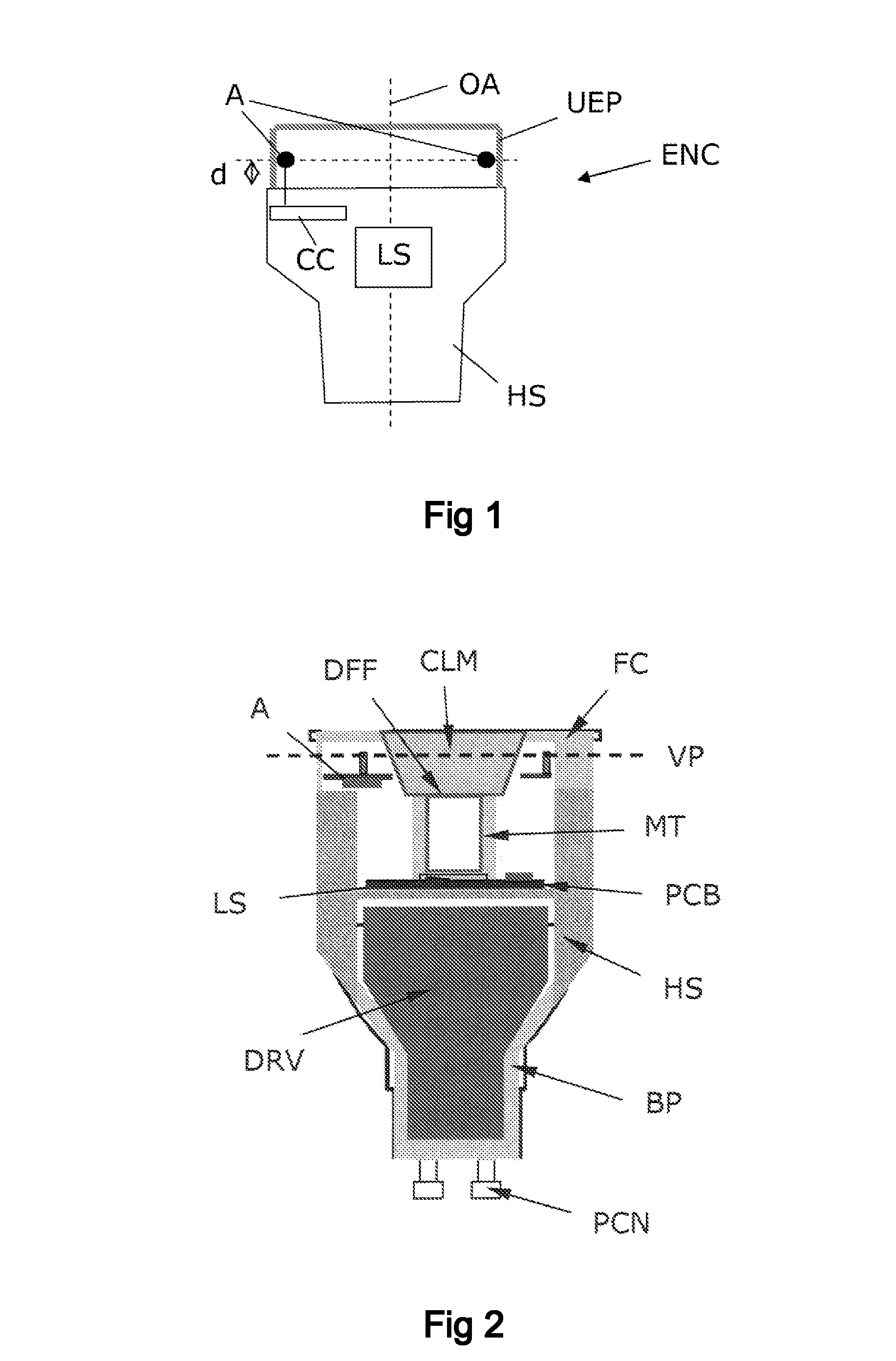

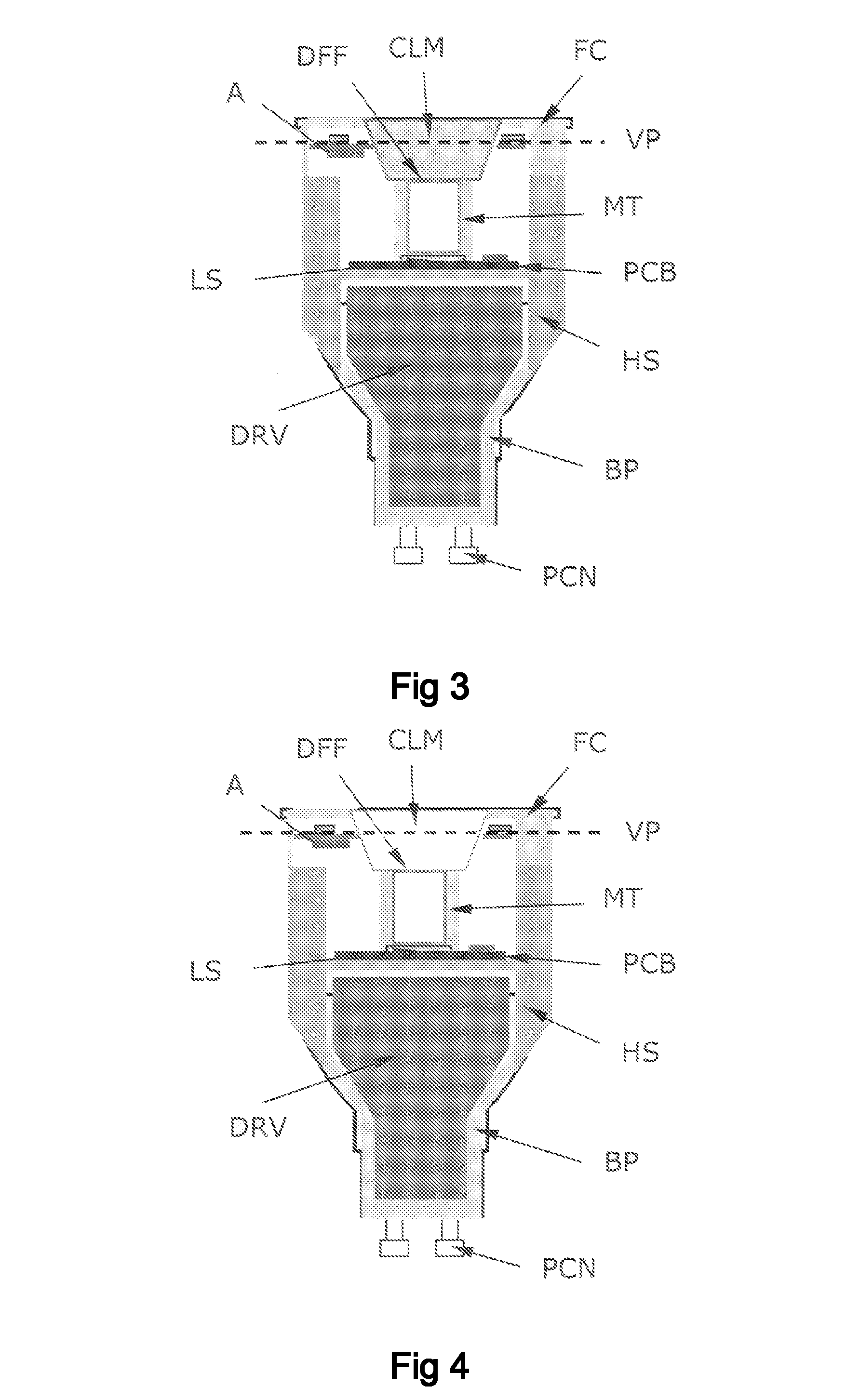

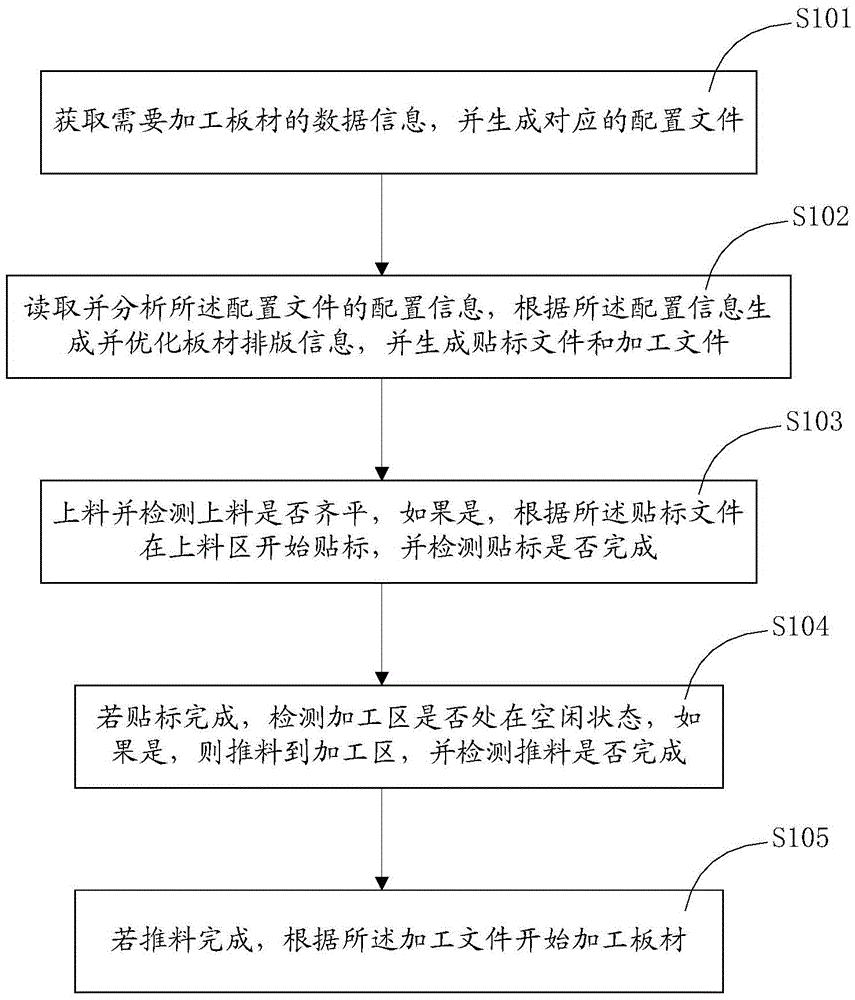

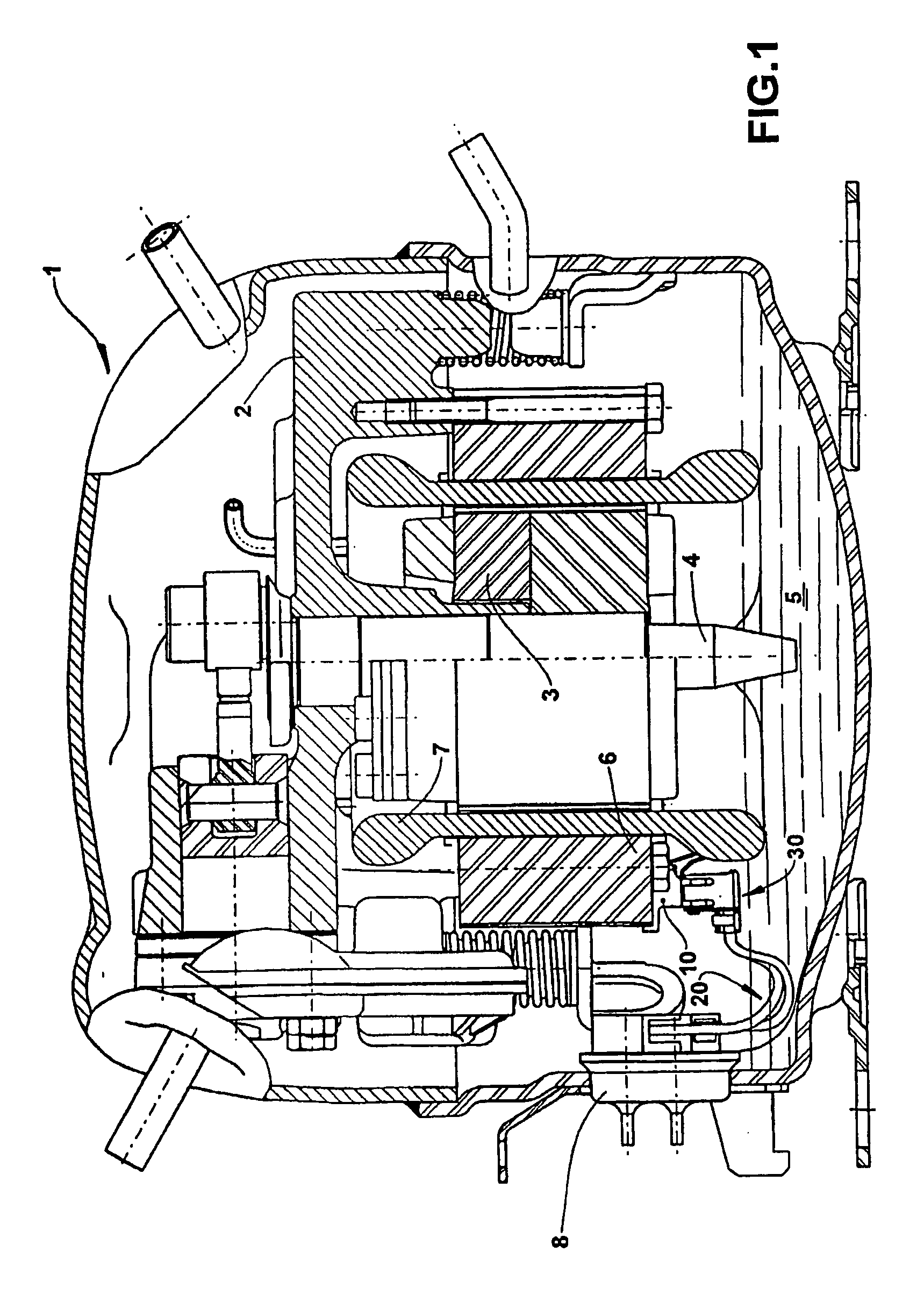

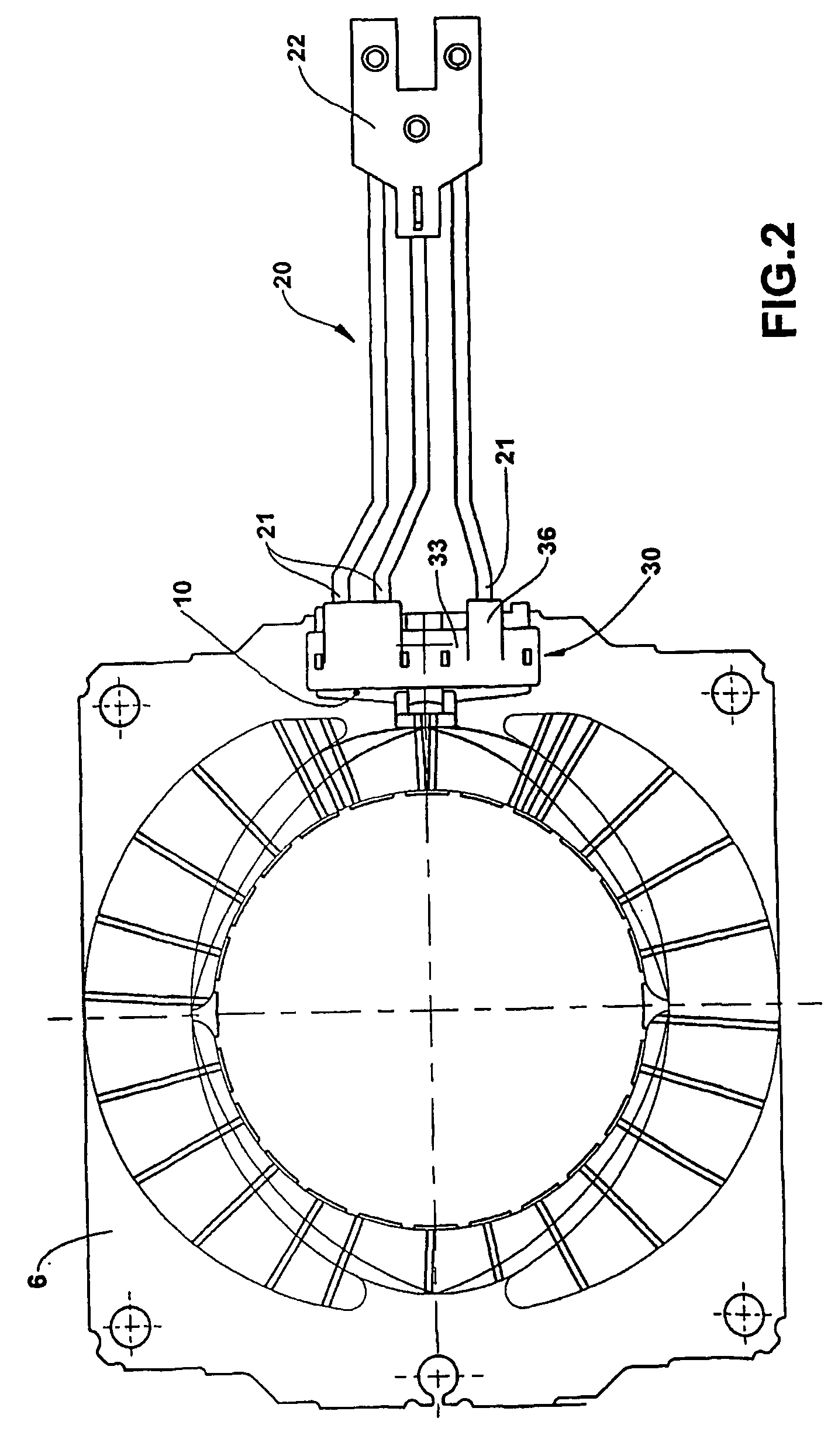

Lighting device with built-in RF antenna

ActiveUS20120274208A1Remove unavoidable heat dissipationSmall sizeLight source combinationsPoint-like light sourceRemote controlOptical axis

A lighting device, such as a replacement lighting device, comprising a light source (LS), e.g. LEDs, for producing light along an optical axis (OA). A heat sink (HS) made of a material with an electrical resistivity being less than 0.01 Ωm, e.g. a metallic heat sink being a part of the housing, transports heat away from the light source (LS). A Radio Frequency (RF) communication circuit (CC) connected to an an antenna (A) serves to enable RF signal communication, e.g. to control the device via a remote control. Metallic components, including the heat sink (HS), having an extension larger than 1 / 10 of a wavelength of the RF signal are arranged below a virtual plane (VP) drawn orthogonal to the optical axis (OA) and going through the antenna (A). Hereby a compact device can be obtained, and still a satisfying RF radiation pattern can be obtained. The antenna can be a wire antenna or a PCB antenna, e.g. a PIFA or a IFA type antenna. In a special embodiment the antenna is formed on a ring-shaped PCB with a central hole allowing passage of light from the light source. Preferably, the antenna is positioned at least 2 mm in front of the heat sink (HS).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

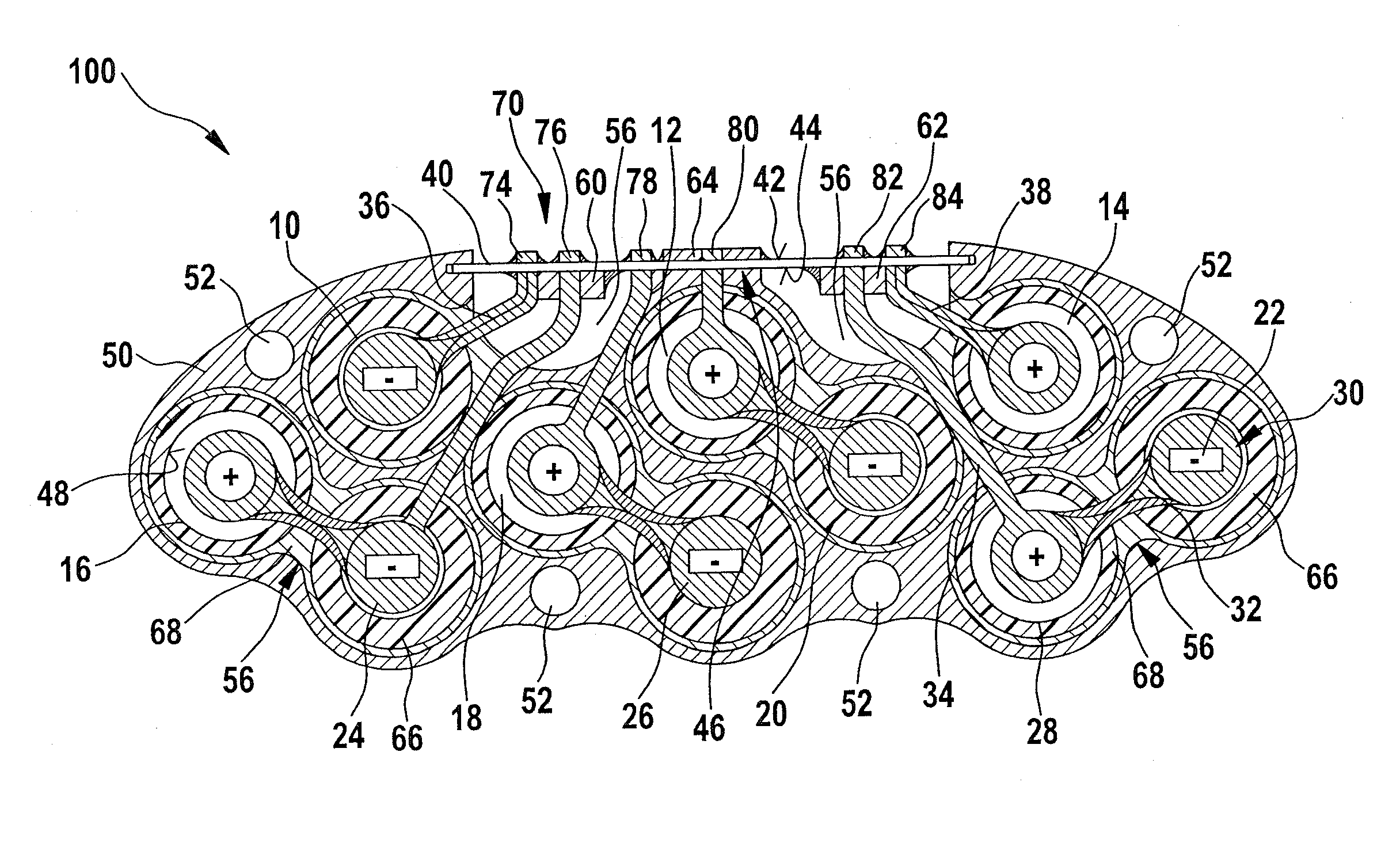

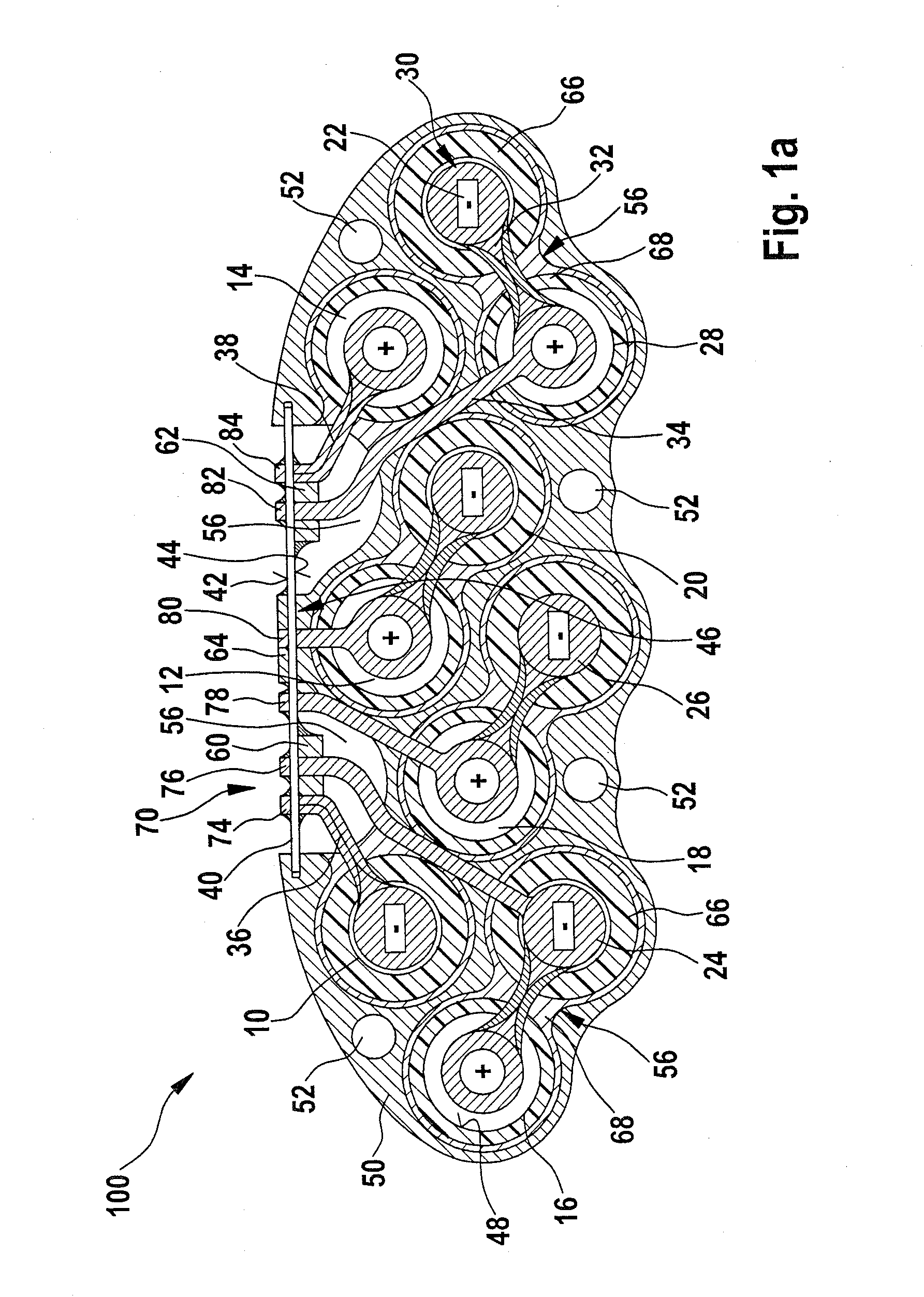

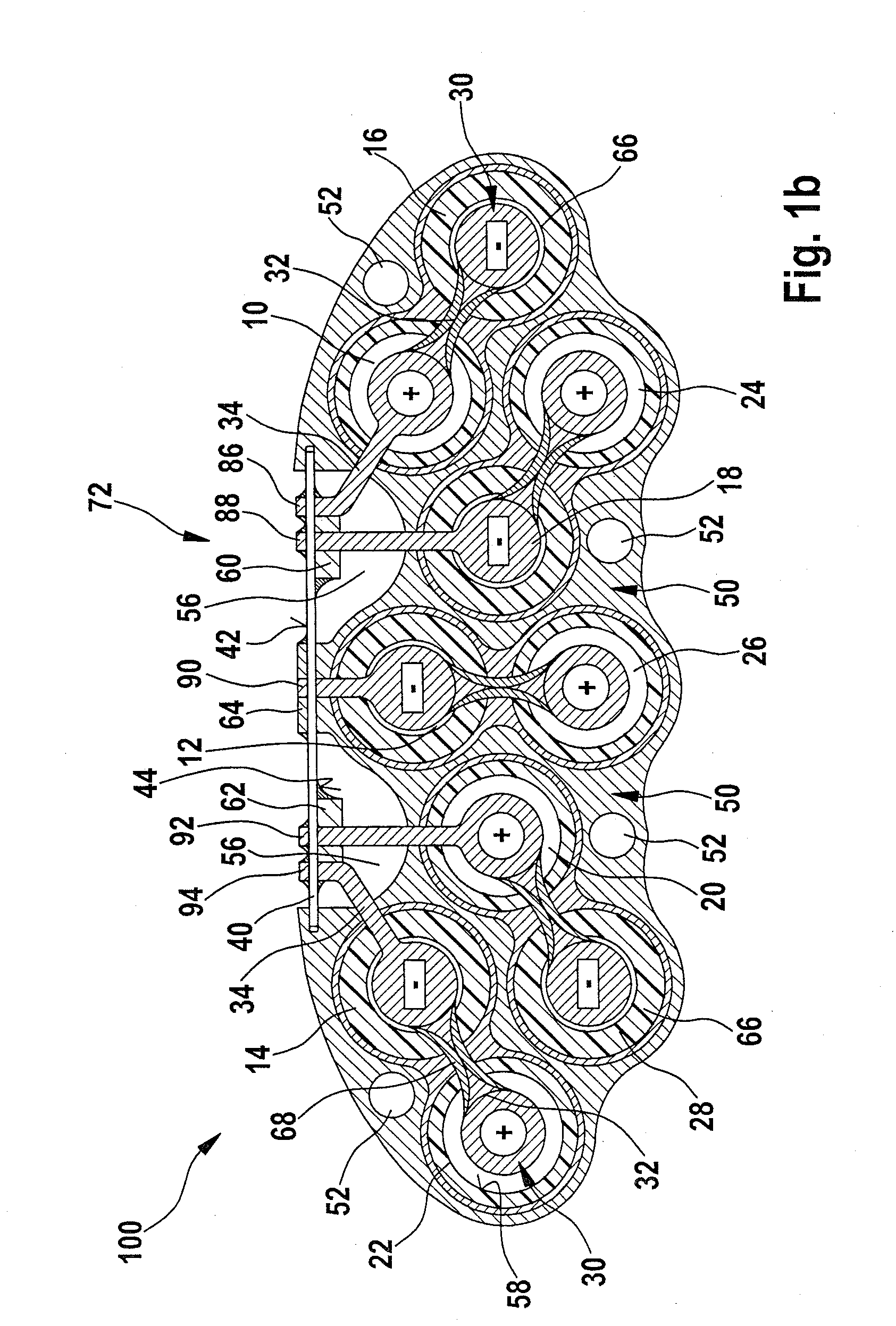

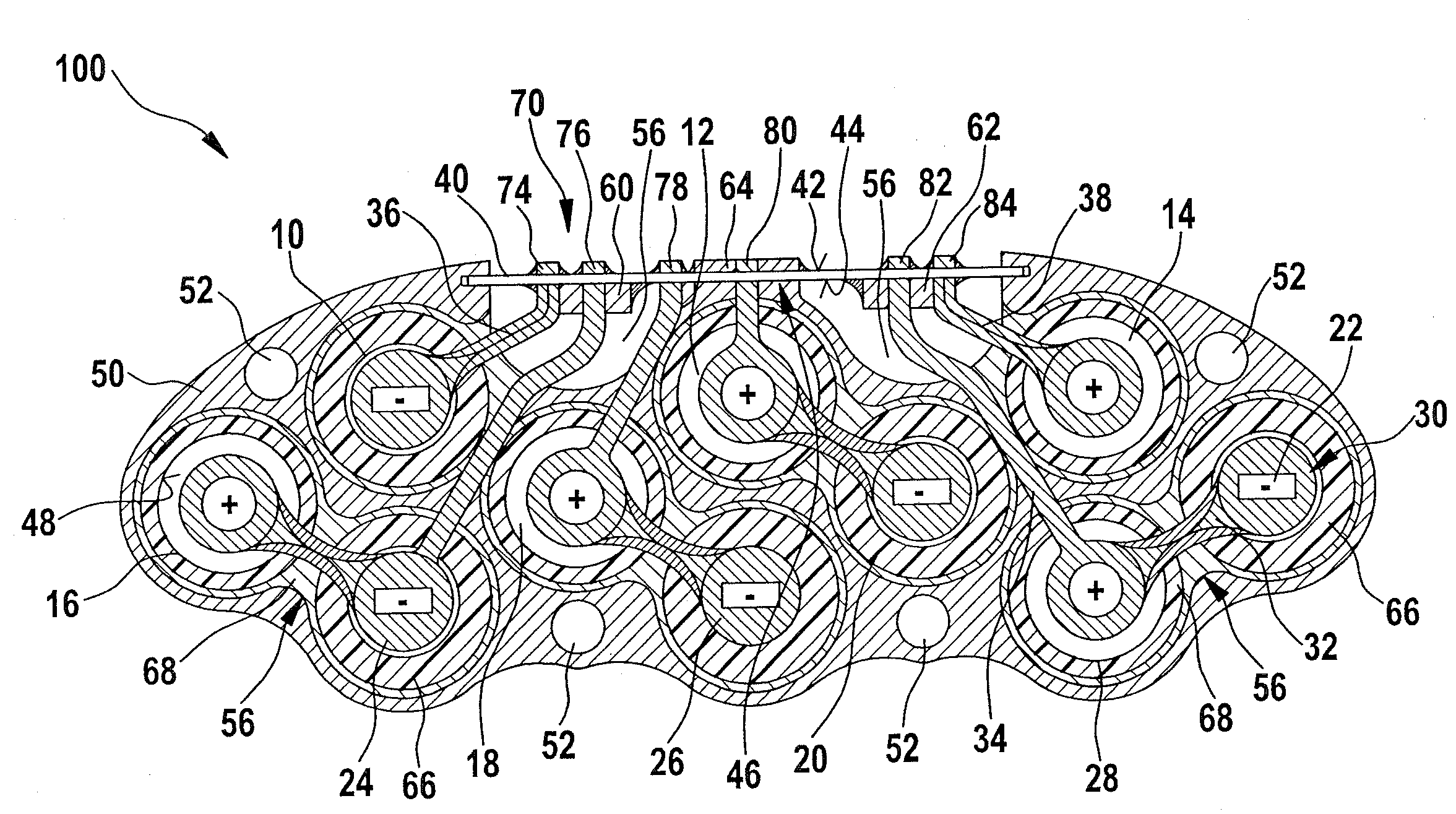

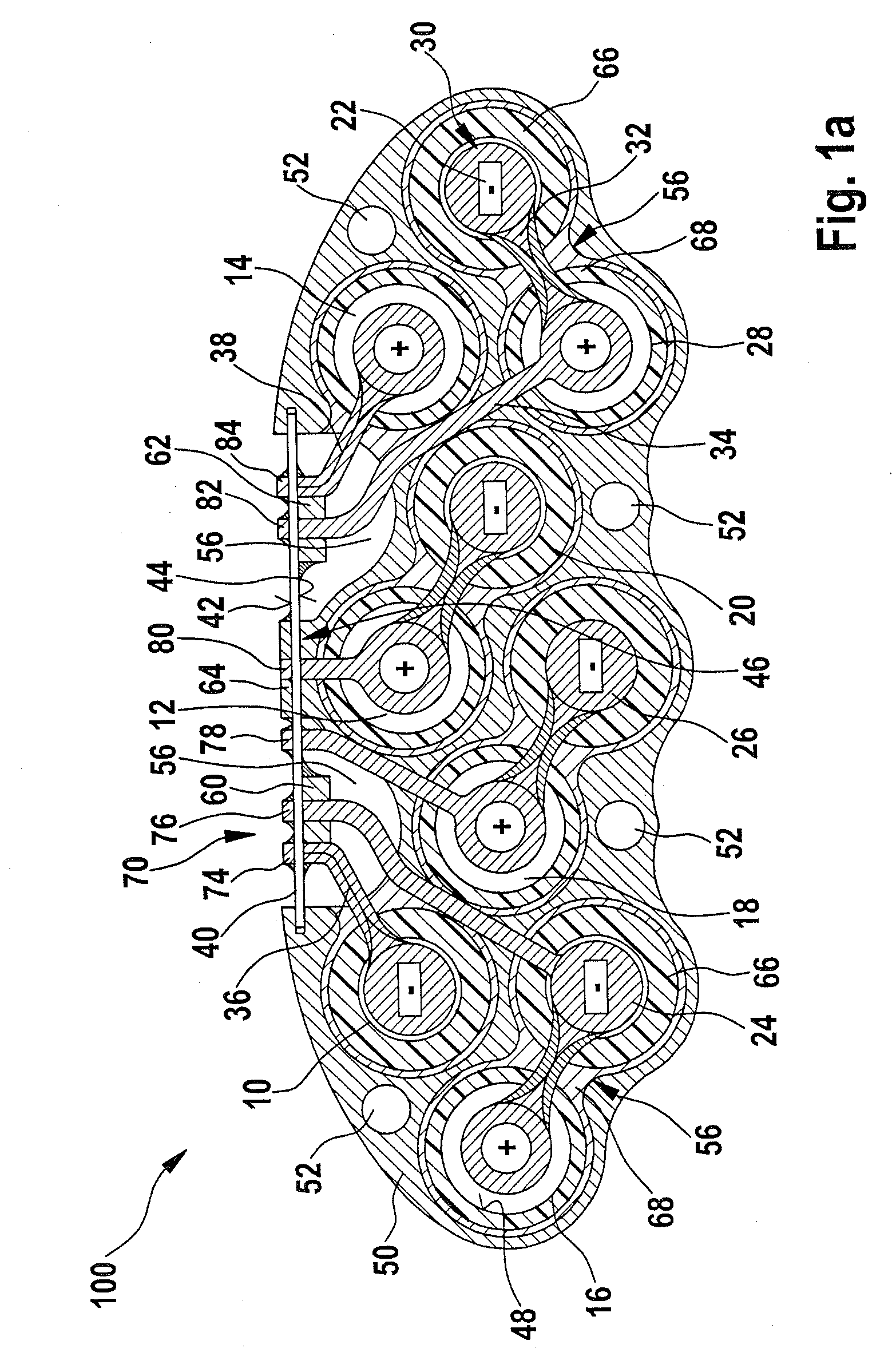

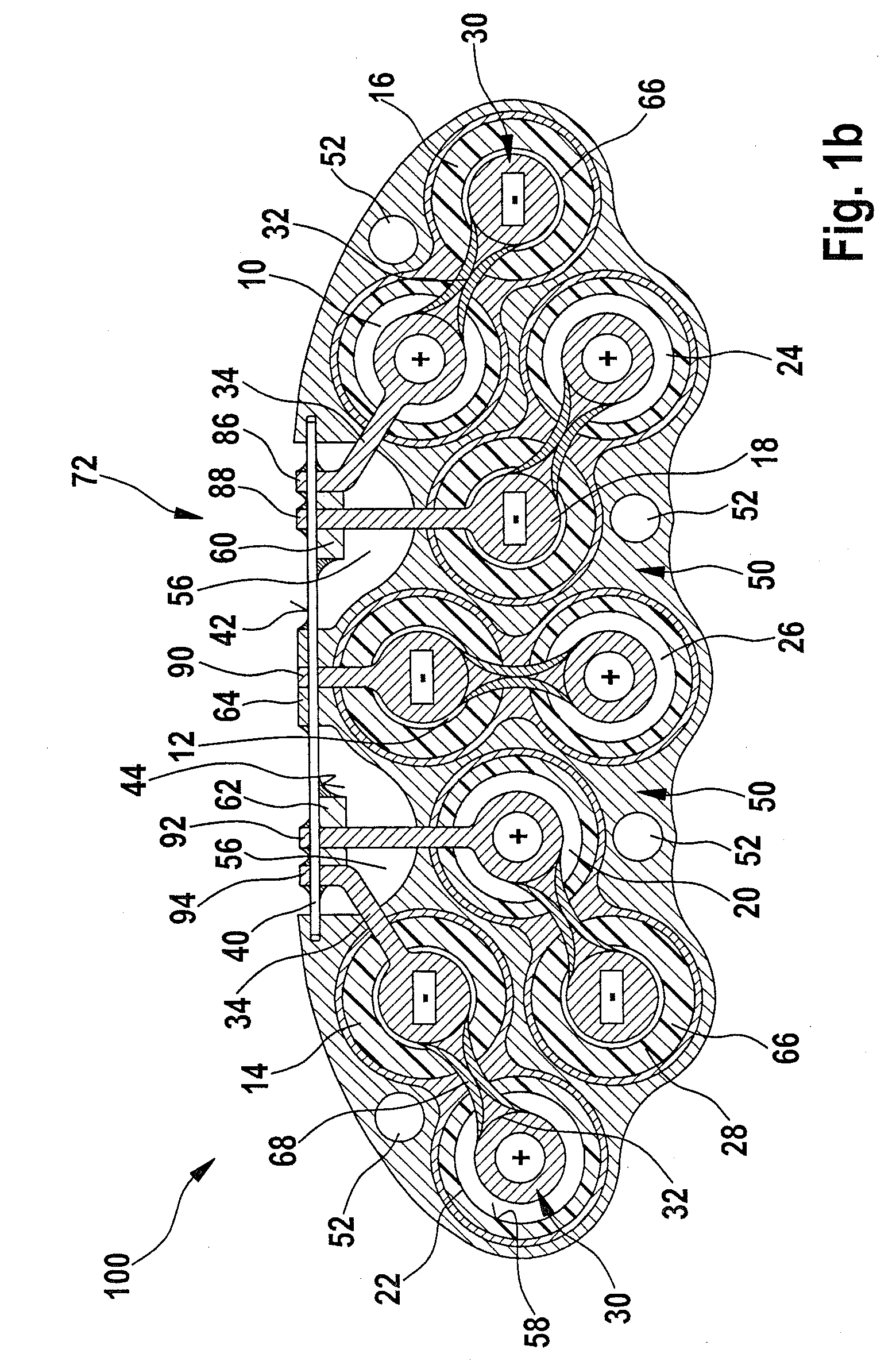

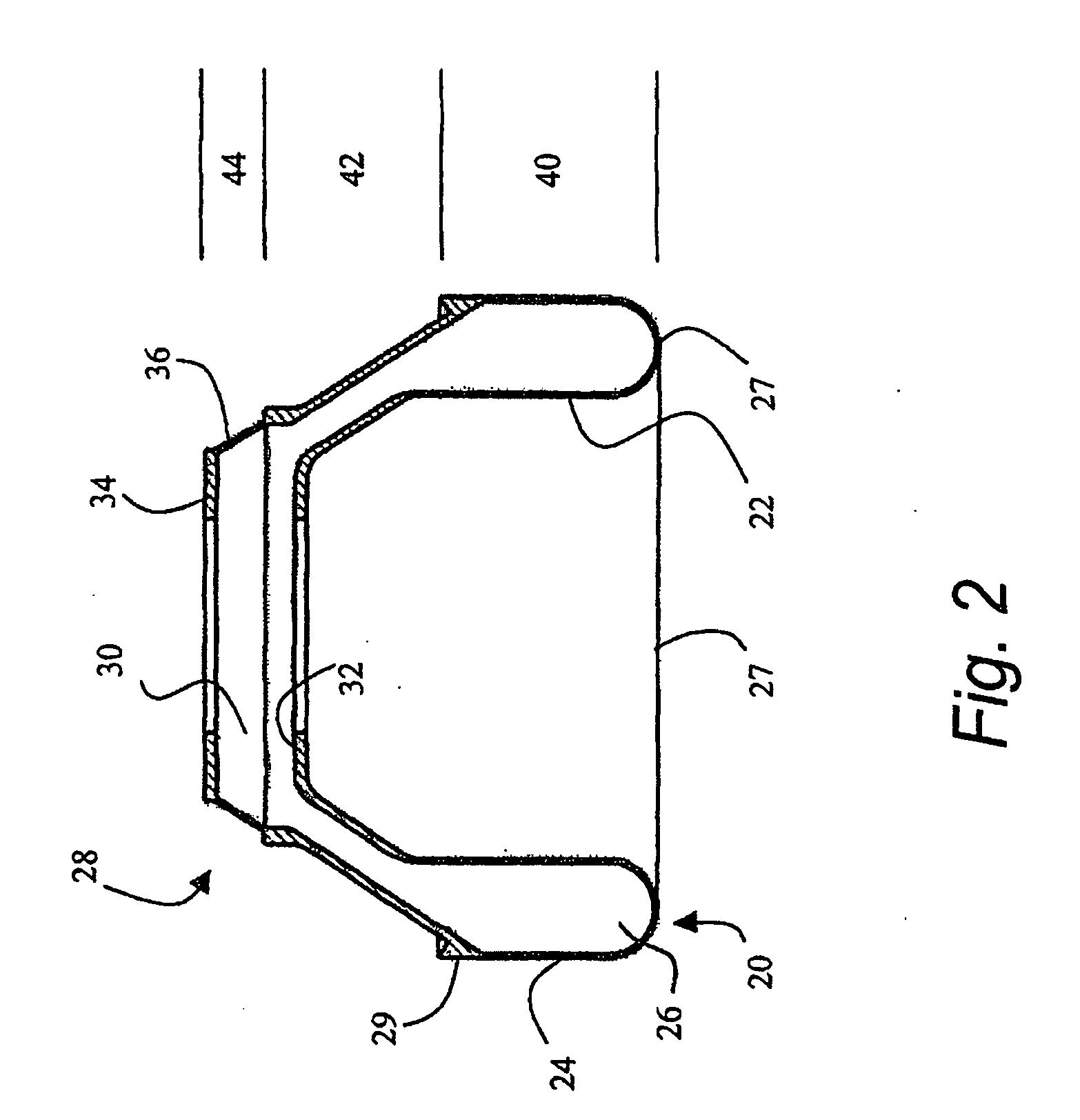

Battery pack and battery module and method for operating a battery module

ActiveUS20080152993A1Shorten cycle timePreparation automationPrimary cell to battery groupingBatteries circuit arrangementsLithiumCell bodies

A battery pack with at least two electrochemical cells, lithium ion cells in particular, has each cell including a positive pole and a negative pole on the end face of the particular cell body, the poles of the cells being electrically connected in series and / or in parallel. A cell connector for electrically connecting the cells is provided on at least two cells, on the end face on the same side relative to their position in the battery pack, the cell connector connecting one pole of the connected cells and extending to a contact region of a circuit board; the cell bodies of the cells are positioned parallel to each other, and the end faces of the cell bodies are located in the same plane.

Owner:ROBERT BOSCH GMBH

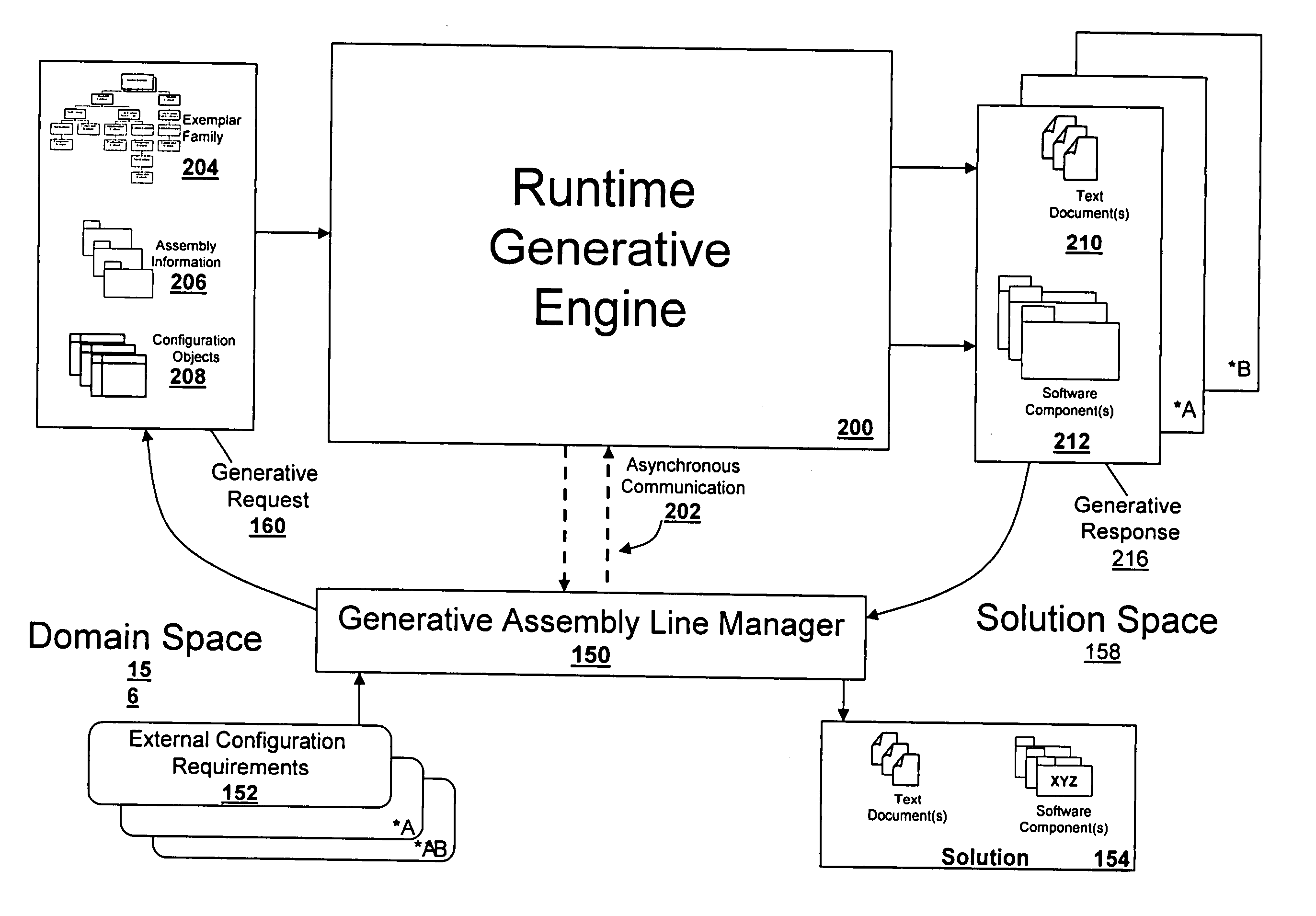

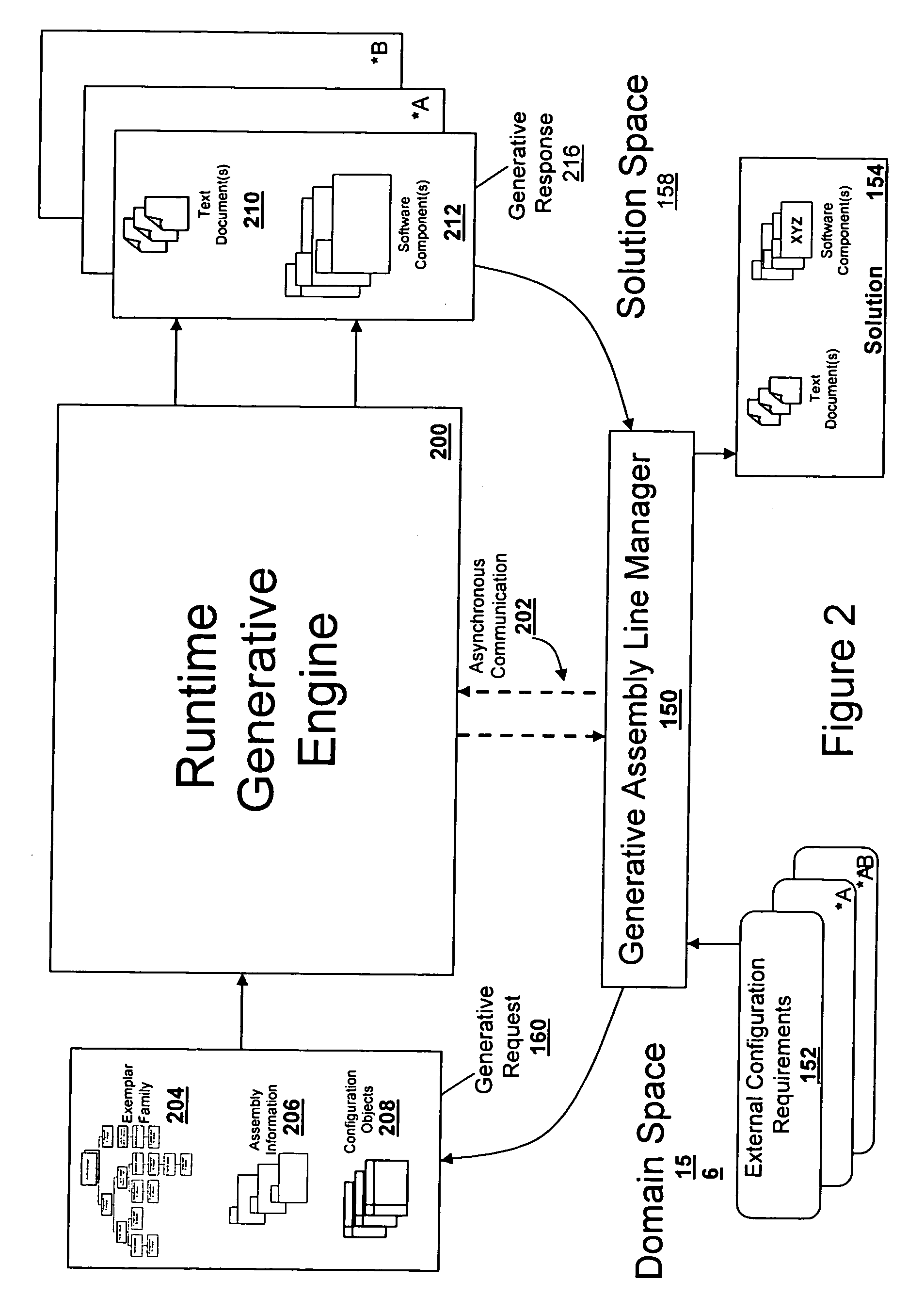

Runtime generative programming method and system

InactiveUS20070028208A1Preparation automationAvoid less flexibilityModel driven codeSoftware reuseSoftware developmentSoftware engineering

A real time code generator which automates the manufacture of software components and software systems based on a method for the runtime configuration and generation of text documents and software components. The text documents and software components are automatically generated within a defined domain through the use of generative tools. Advantageously, the automation and generation occurs at runtime such that the generative system senses changes to domain-specific configuration requirements and, in response, generates a fully executable runtime solution. The present method enables generative software development to occur during runtime, resulting in the automatic generation of compiled software components that can be deployed within a CBSE environment to create a product or system variant.

Owner:MAKI ALEC

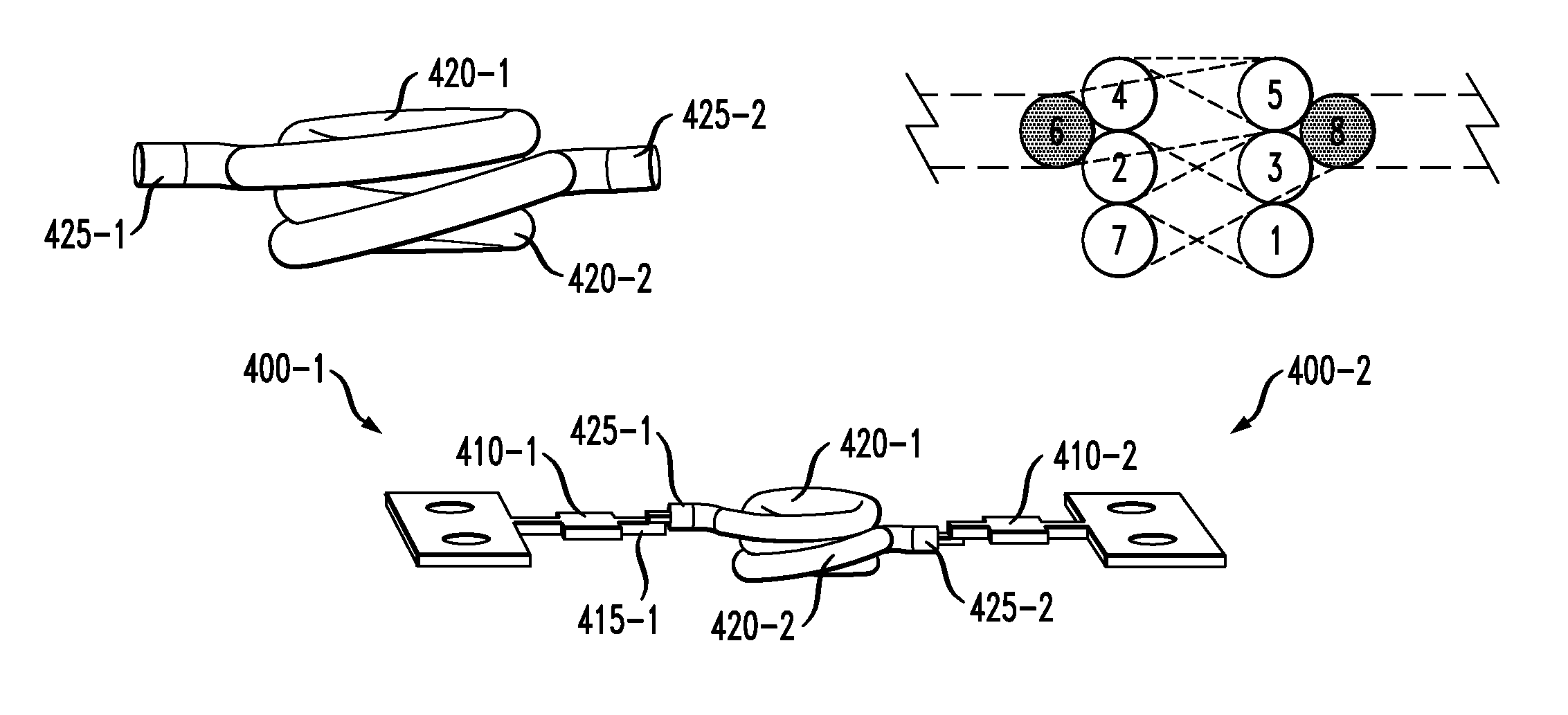

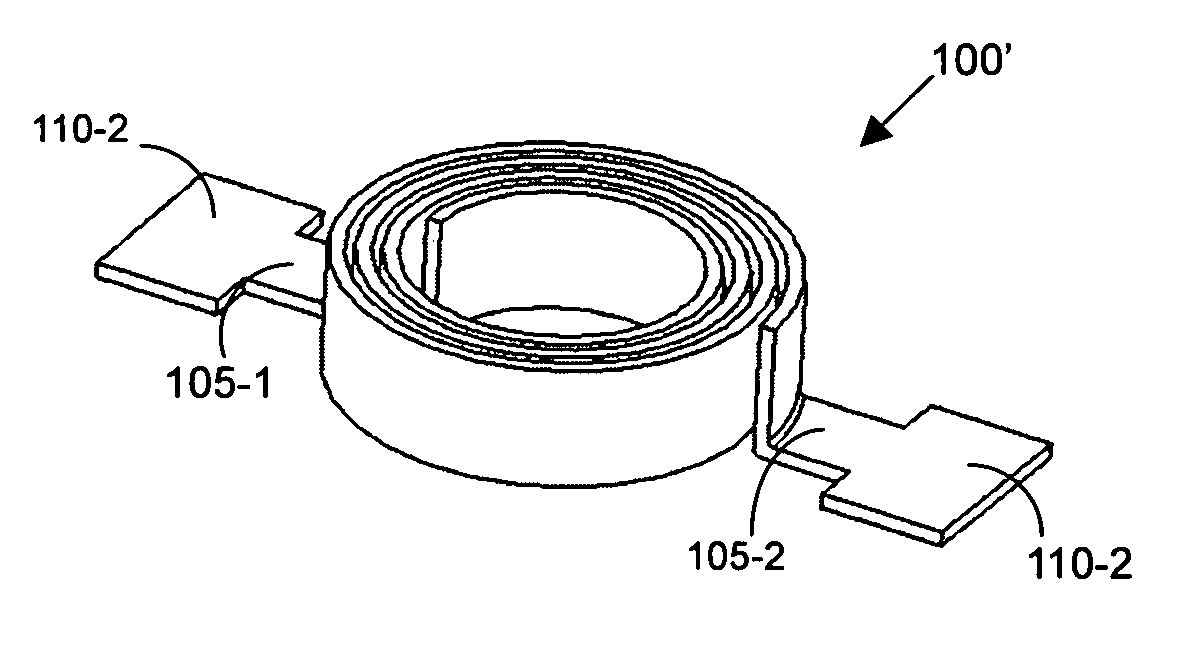

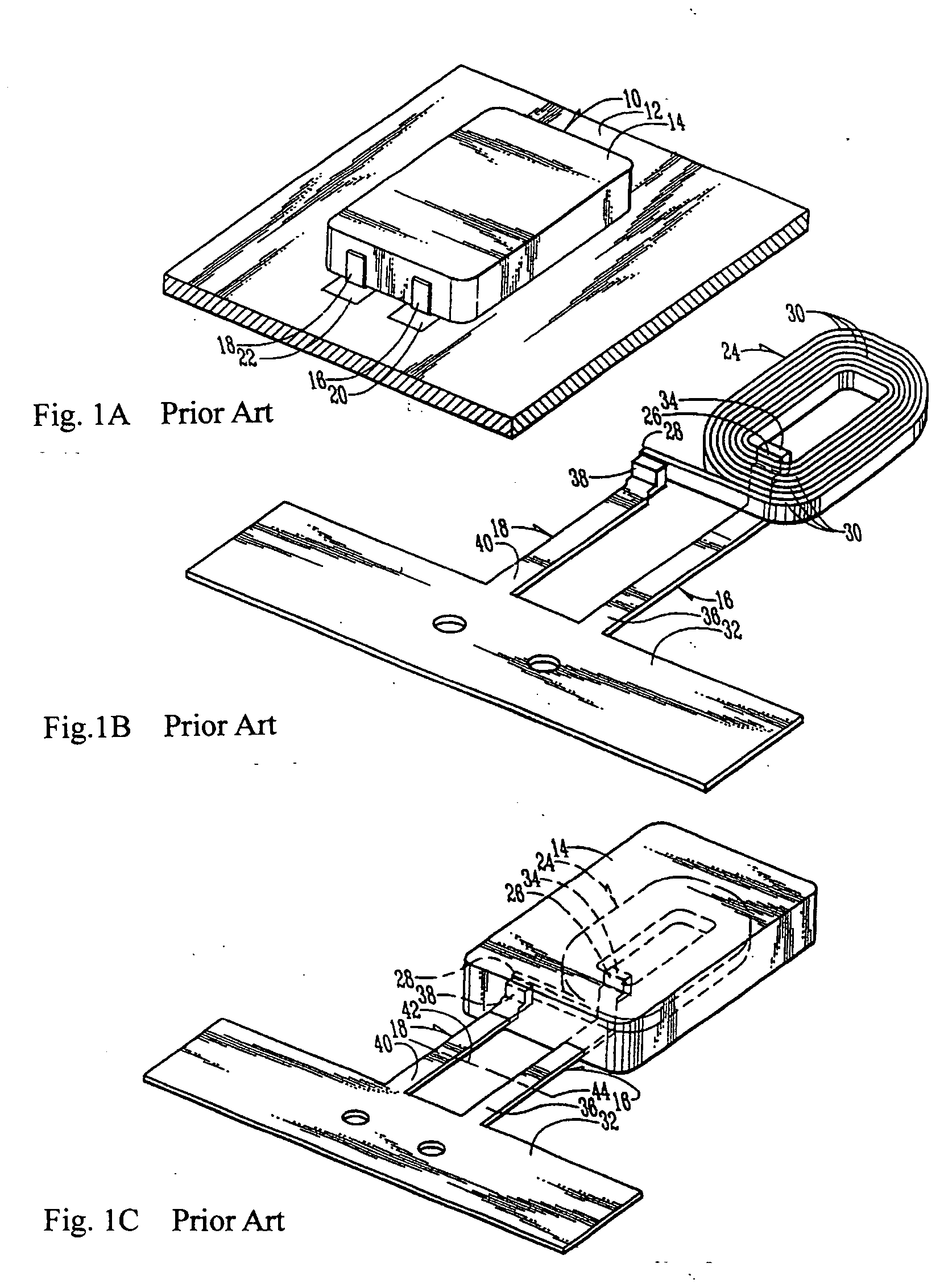

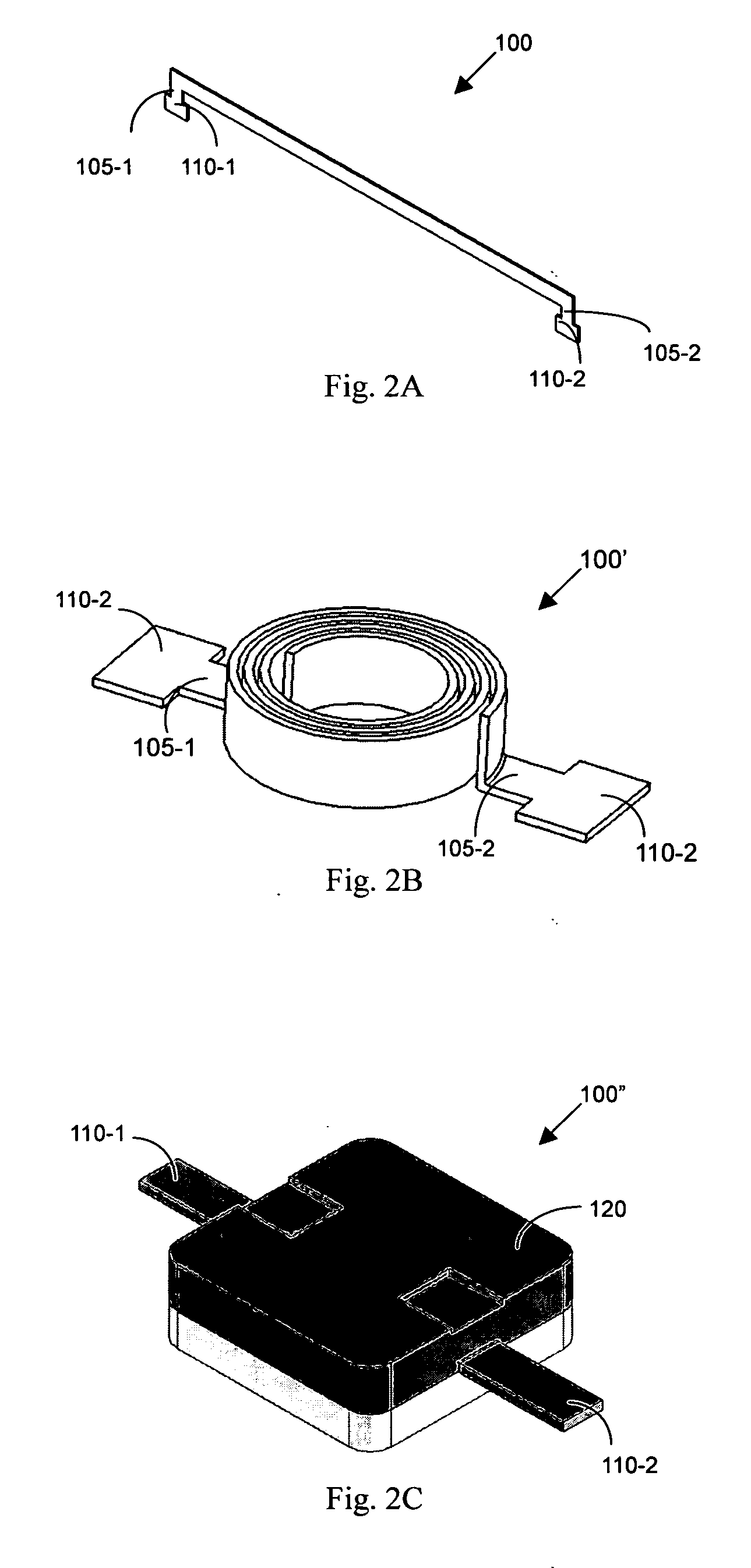

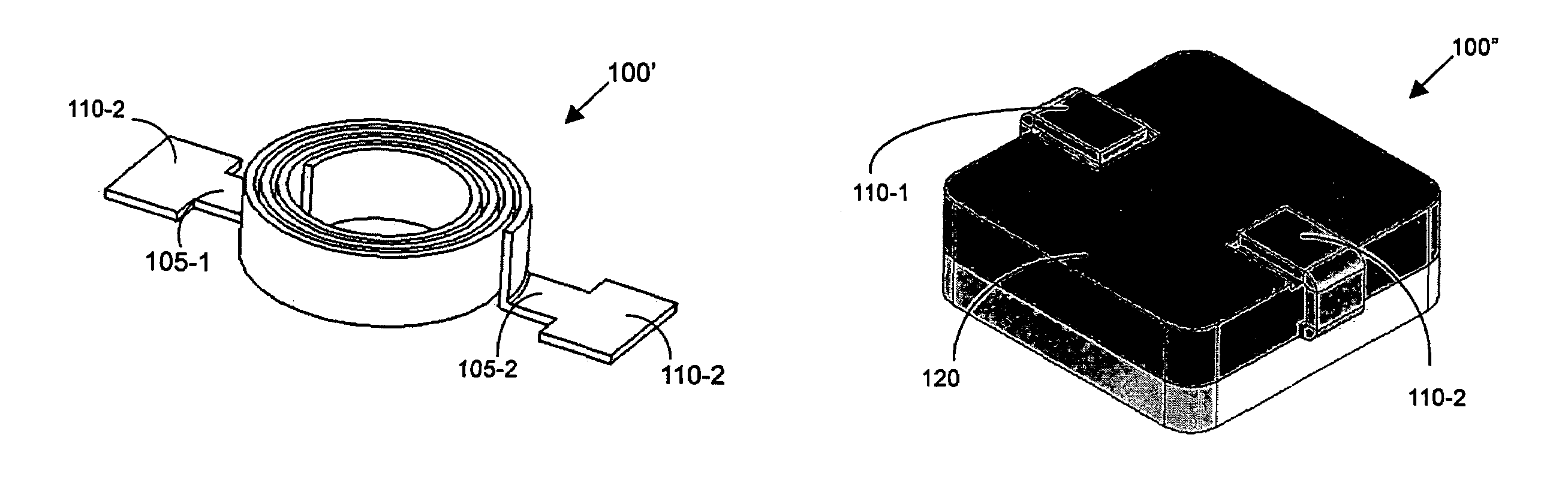

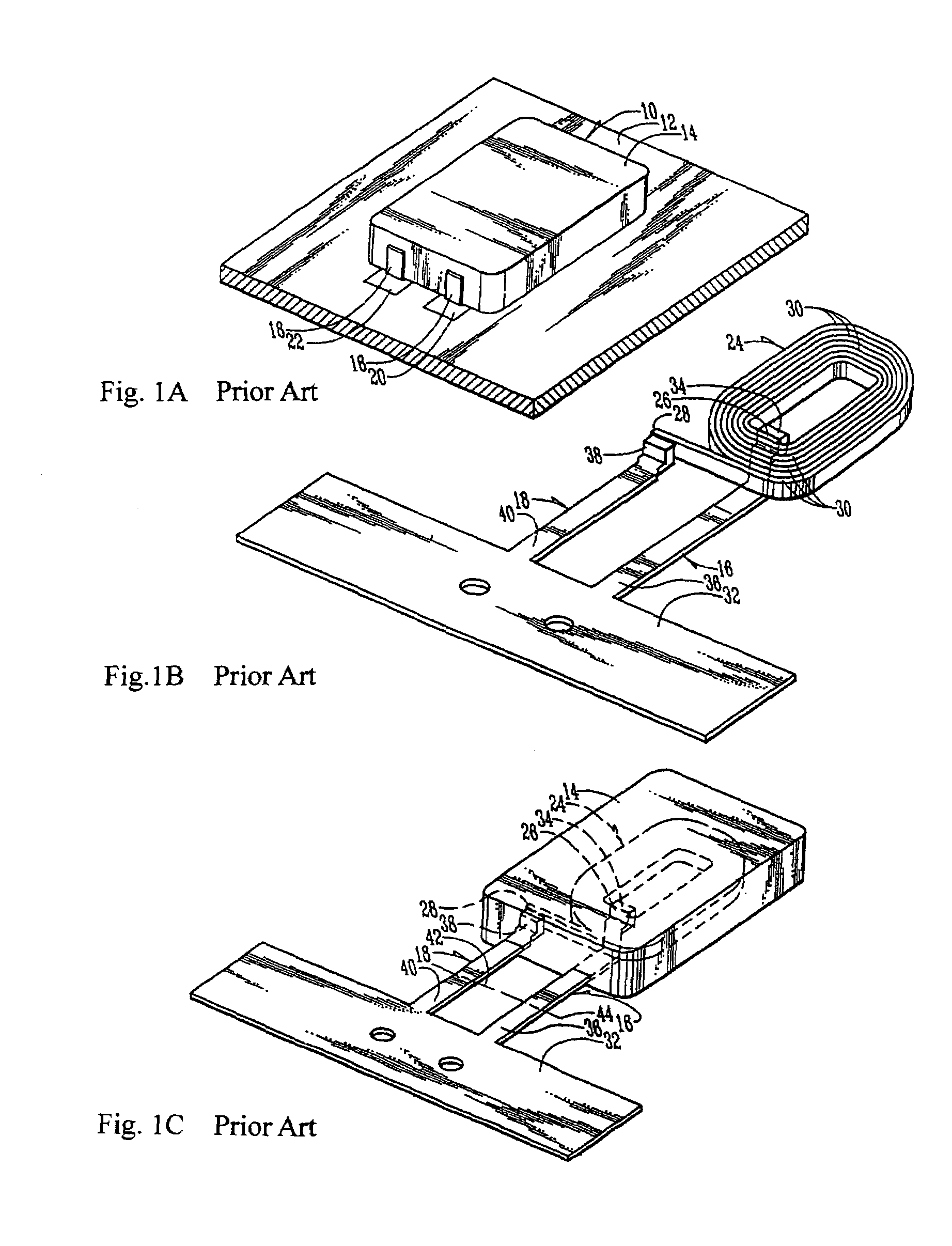

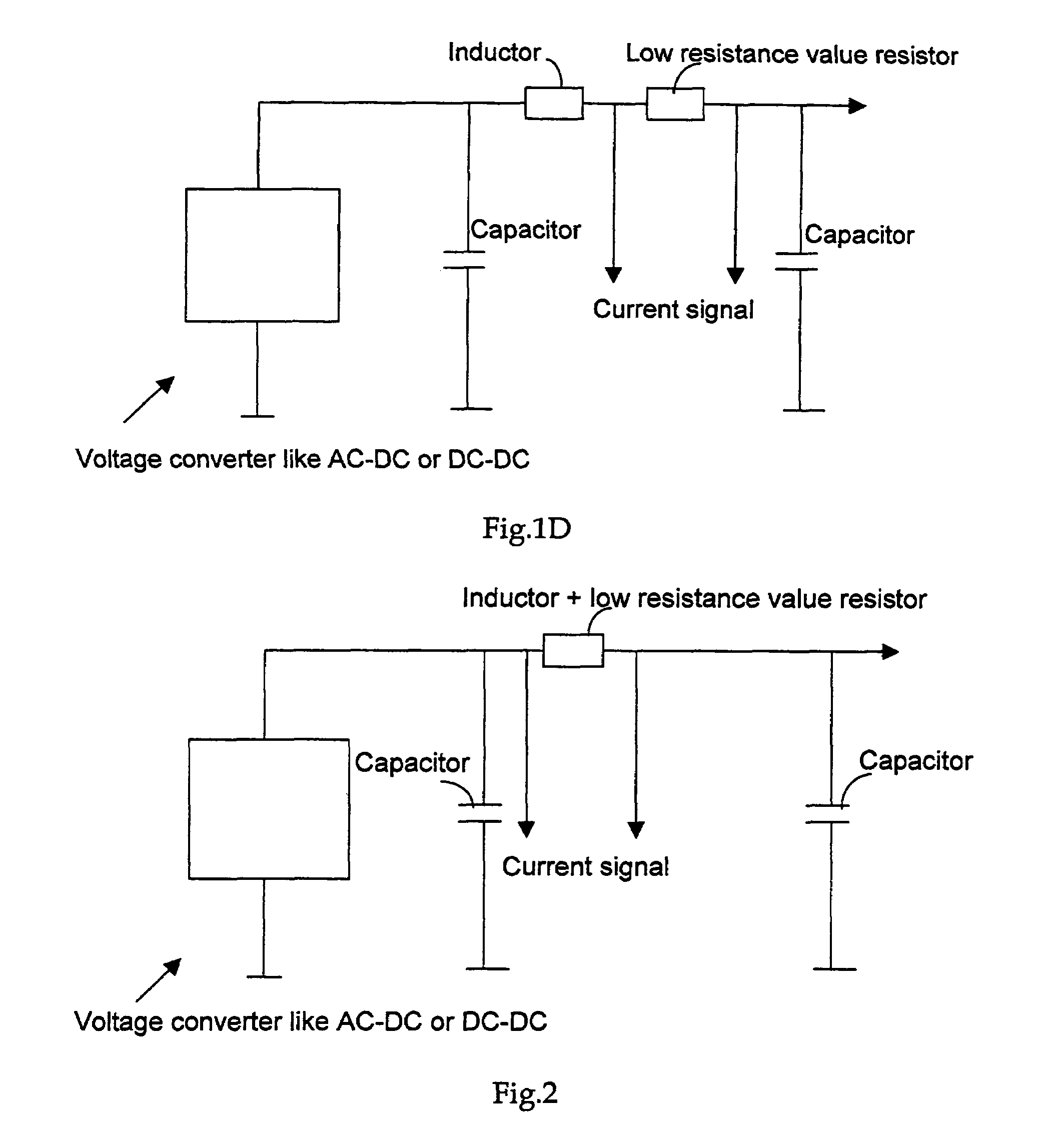

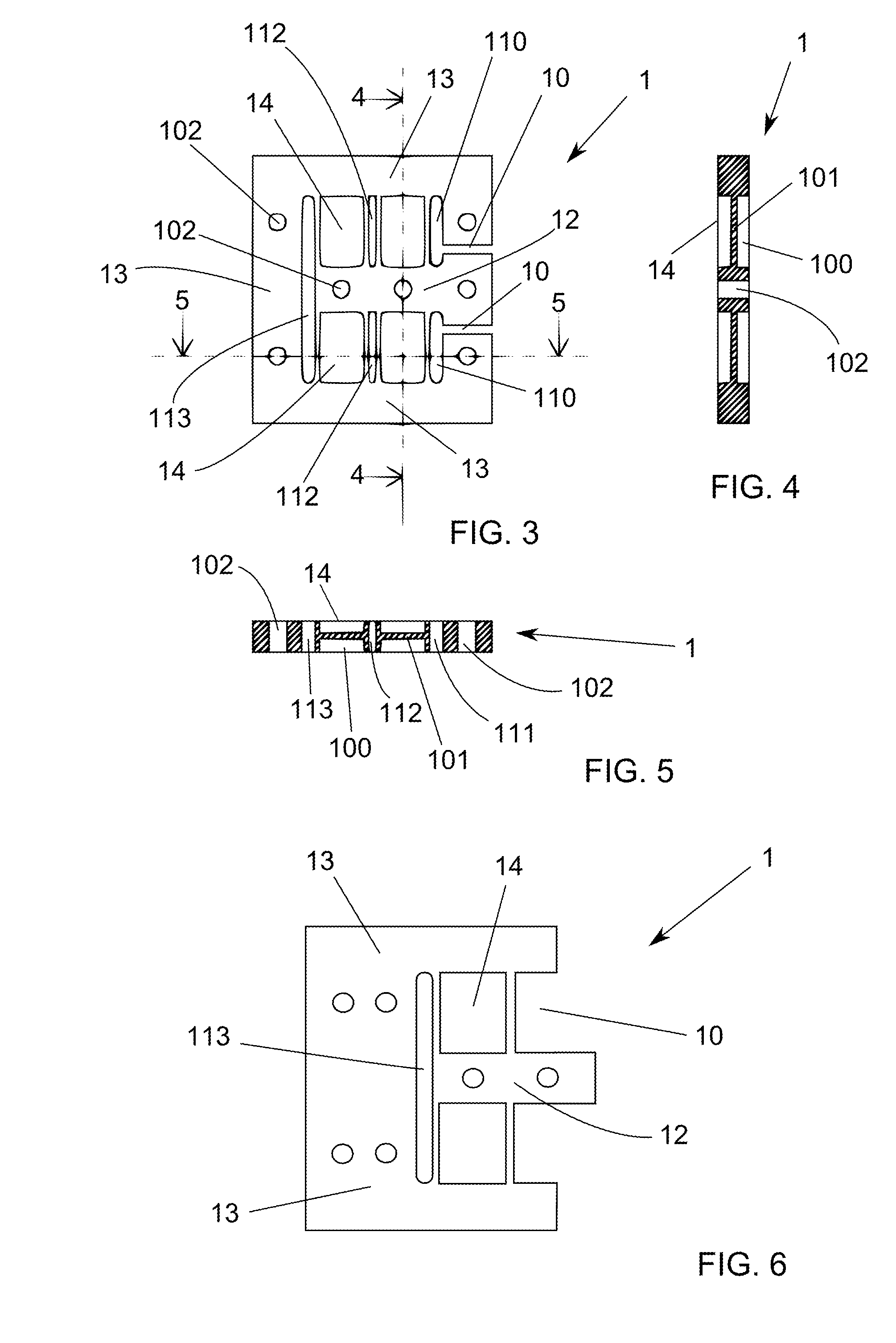

Inductor

ActiveUS7339451B2Simple manufacturing processSmall heightTransformers/inductances detailsInductance with magnetic coreInductorConductor Coil

This invention discloses an inductor including a conducting wire having a winding configuration provided for enclosure in a substantially rectangular box with a mid-plane extended along an elongated direction of the rectangular box wherein the conducting wire intersecting at least twice near said mid-plane.

Owner:CYNTEC

Configuration and method to manufacture compact inductor coil with low production cost

ActiveUS20060049906A1Simple manufacturing processSmall heightTransformers/inductances detailsInductance with magnetic coreEngineeringInductor

This invention discloses an inductor includes a conducting wire having a winding configuration provided for enclosure in a substantially rectangular box with a mid-plane extended along an elongated direction of the rectangular box wherein the conducting wire interesting at least twice near said mid-plane.

Owner:CYNTEC

Lighting device with built-in RF antenna

ActiveUS9184497B2Wide RF communicationCompact antennaLight source combinationsPoint-like light sourceEffect lightEngineering

Owner:KONINK PHILIPS ELECTRONICS NV

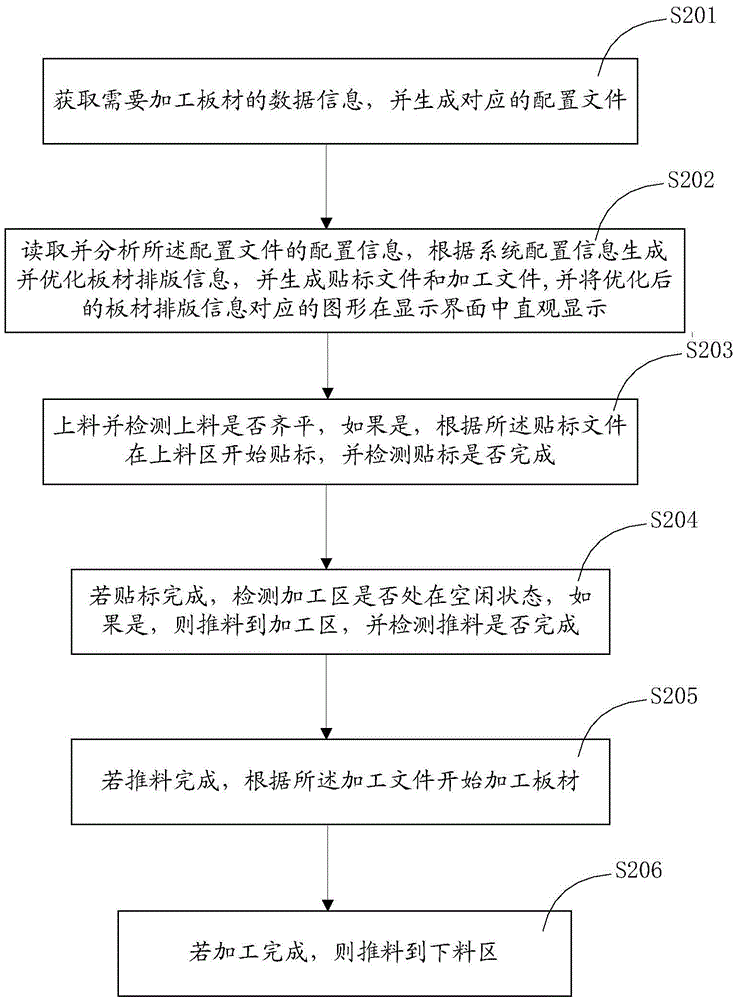

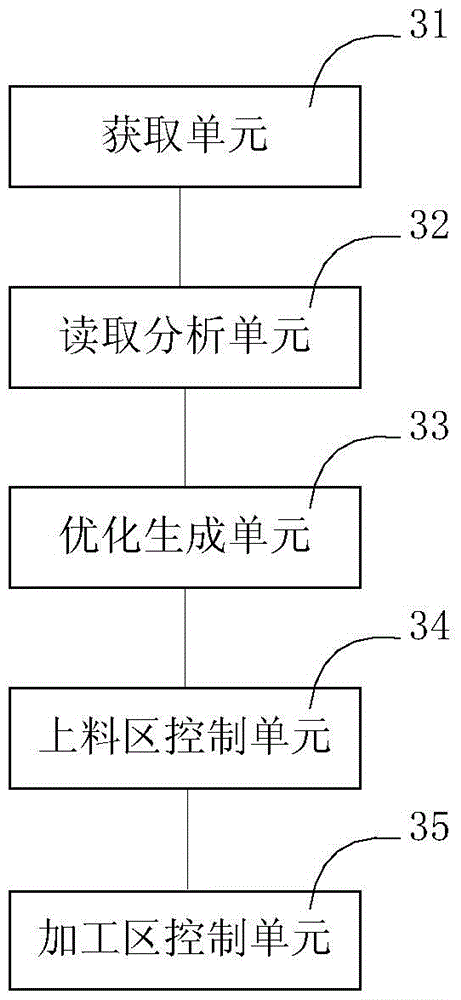

Nesting control method and system

InactiveCN105549536APreparation automationLower requirementProgramme controlComputer controlPunchingEngineering

The invention provides a nesting control method and system, relates to the field of wood work machines, and makes the manufacture process of the nesting plate type furniture more automatic. The whole process from feeding, labeling, pushing material in place, cutting, punching, milling and grooving is monitored and controlled in a fully automatic manner, optimal typesetting composing information is calculated automatically, the rate of waste material is effectively reduced, the composing result is patterned and displayed visually, and the requirement for operators is greatly reduced. Selection and filtering functions are included, the type which is not processed is output, convenience is provided for processing in the next step, and the freedom degree of users is enhanced. Thus, the problems that a present cutting tool is highly dependent on the labor, large in errors, long in operation time and low in the reutilization rate of residual materials are solved.

Owner:广州纬纶信息科技有限公司

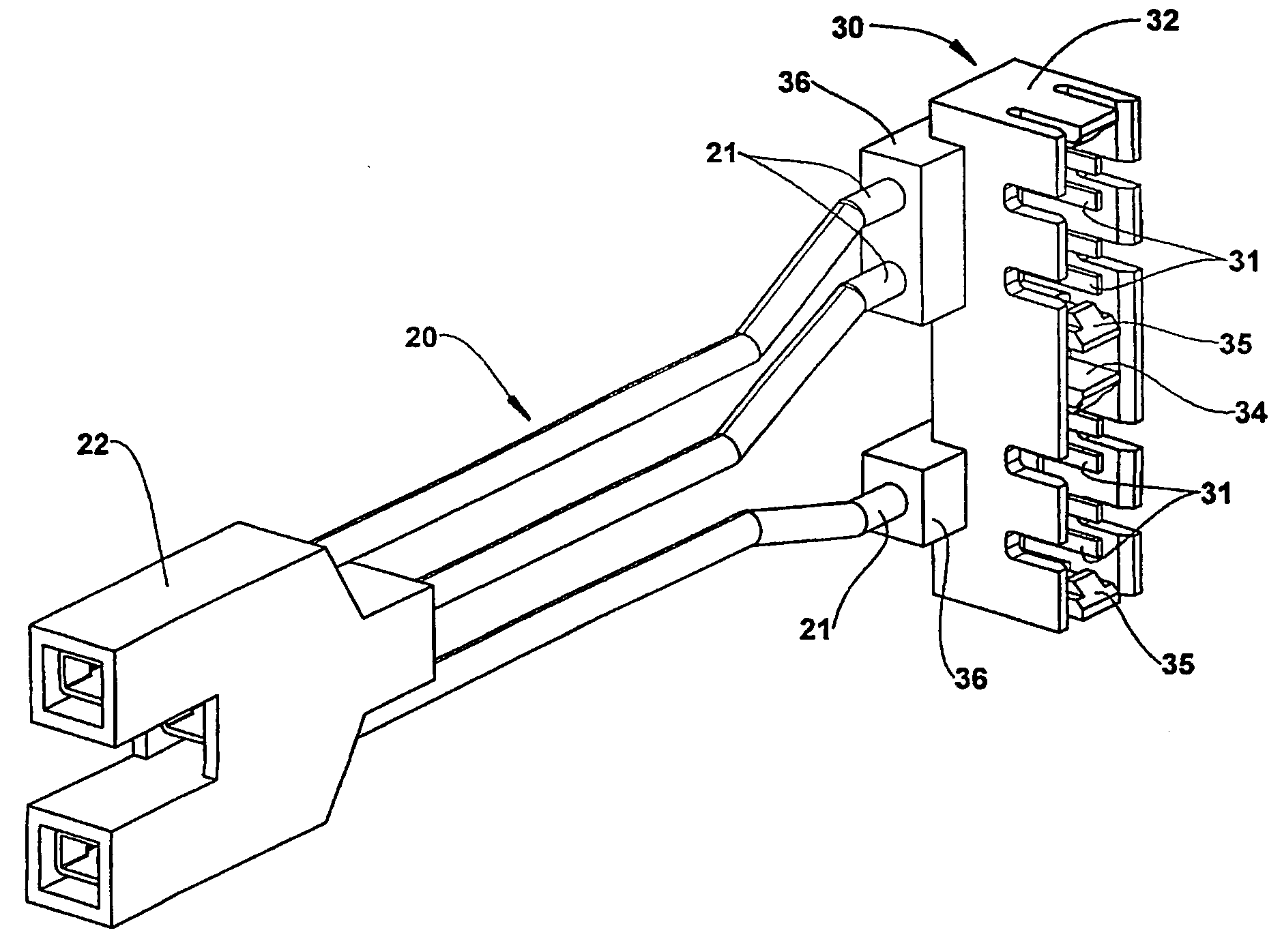

Electric connector for the motor of a hermetic compressor and its manufacturing process

InactiveUS20050054234A1Preparation automationWindingsPositive displacement pump componentsStatorElectrical conductor

An electric connector for the motor of a hermetic compressor and its manufacturing process, said motor carrying in the stator (6) thereof a female connector (10) for electric connection and being mounted inside a shell (1) to which is affixed a power inlet plug (8) for connection to an external current supply source, said connector comprising an electric insulating body to be engaged to the female connector (10) and carrying: a plurality of binding posts (31) connecting and affixing a first end portion (21) of each respective conductor (20), which has a second end portion (22) to be connected to a power inlet plug (8) of the shell (1); and fixation means to be fitted into engagement receiving means provided in the female connector (10), in order to immobilize said parts against relative movements, said male connector (30) being obtained by over-injecting insulating material to each first end portion (21) of each conductor (20) connected to the insulating body of the male connector (30), in order to immobilize said conductors (20).

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

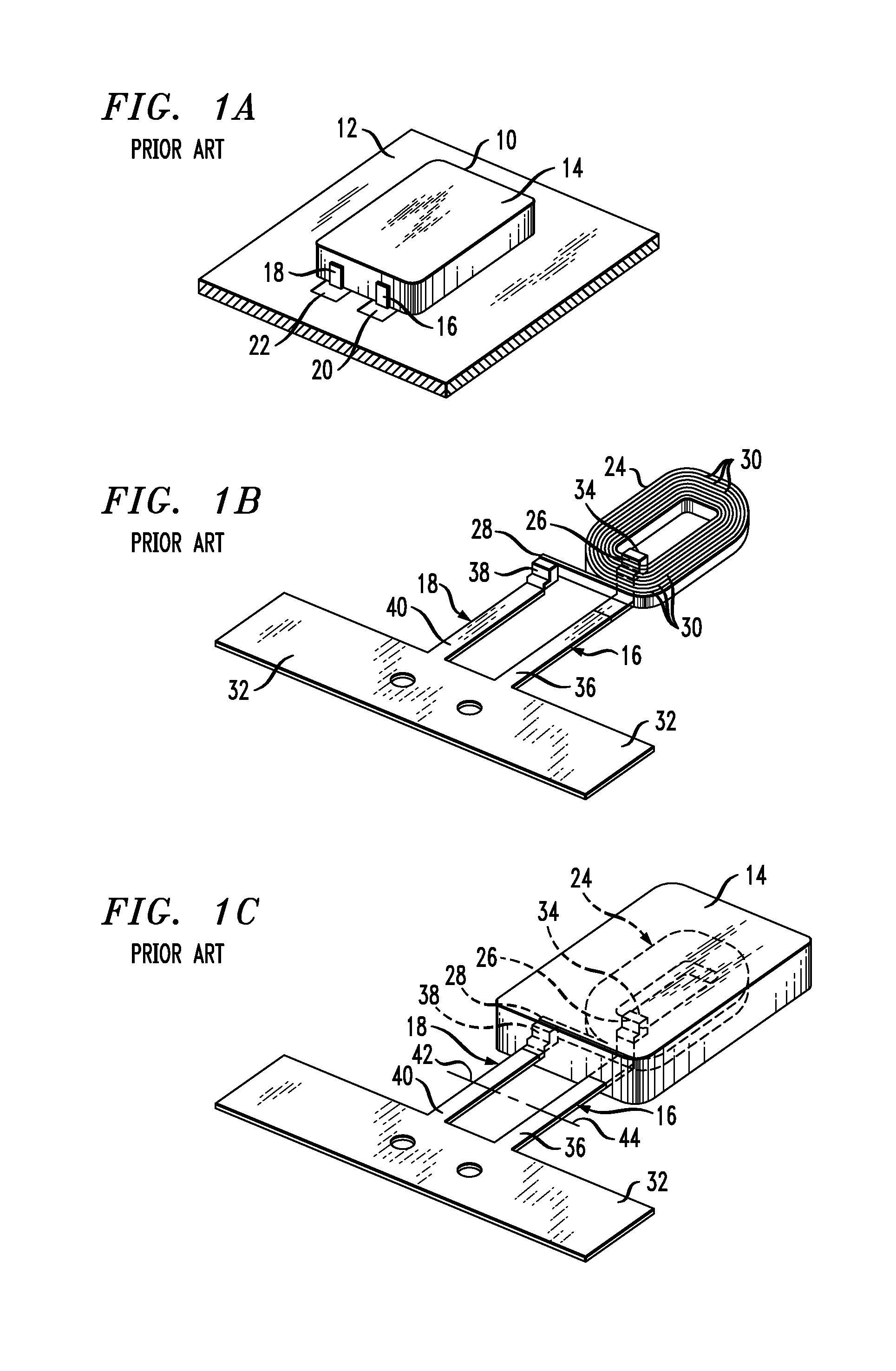

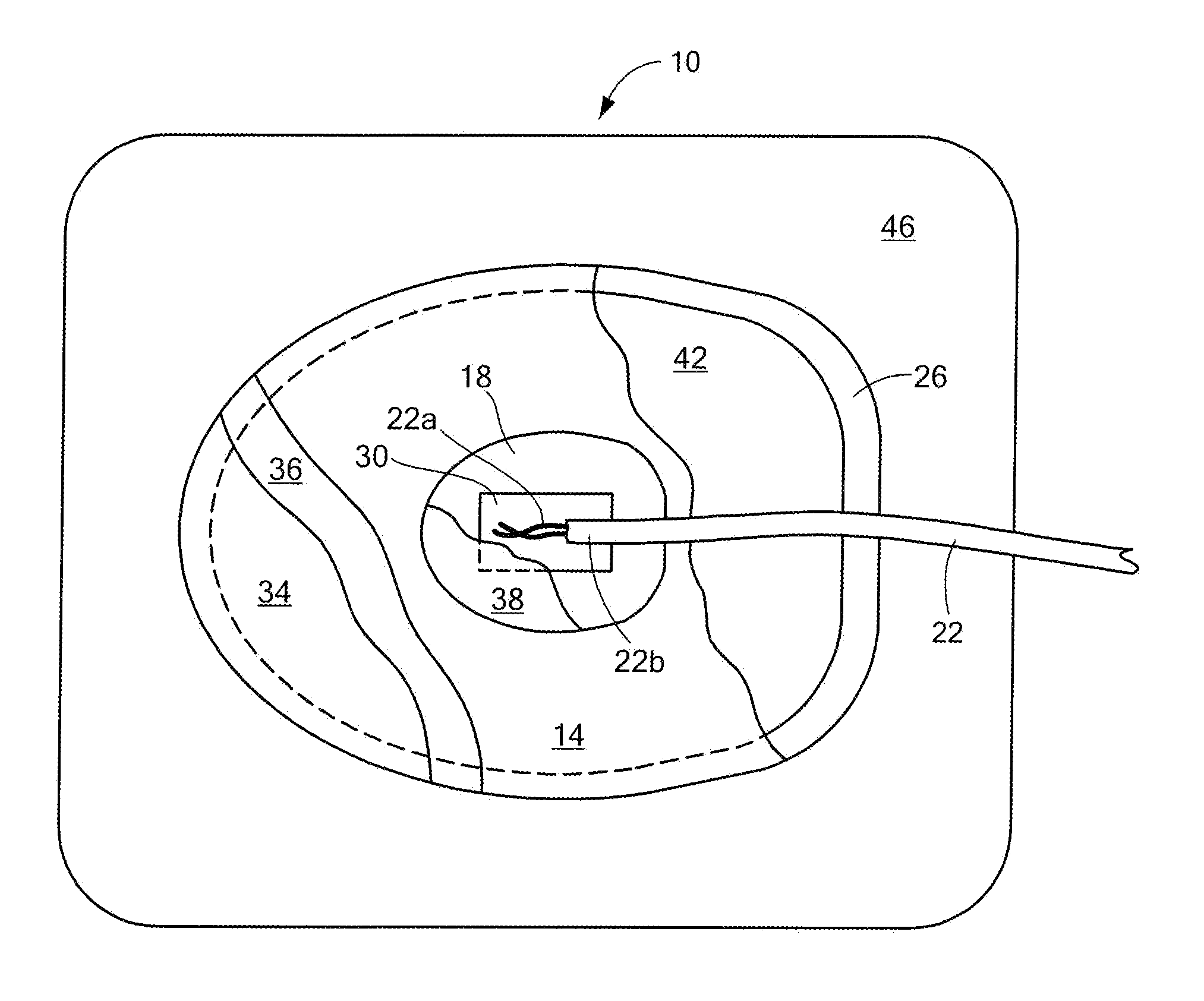

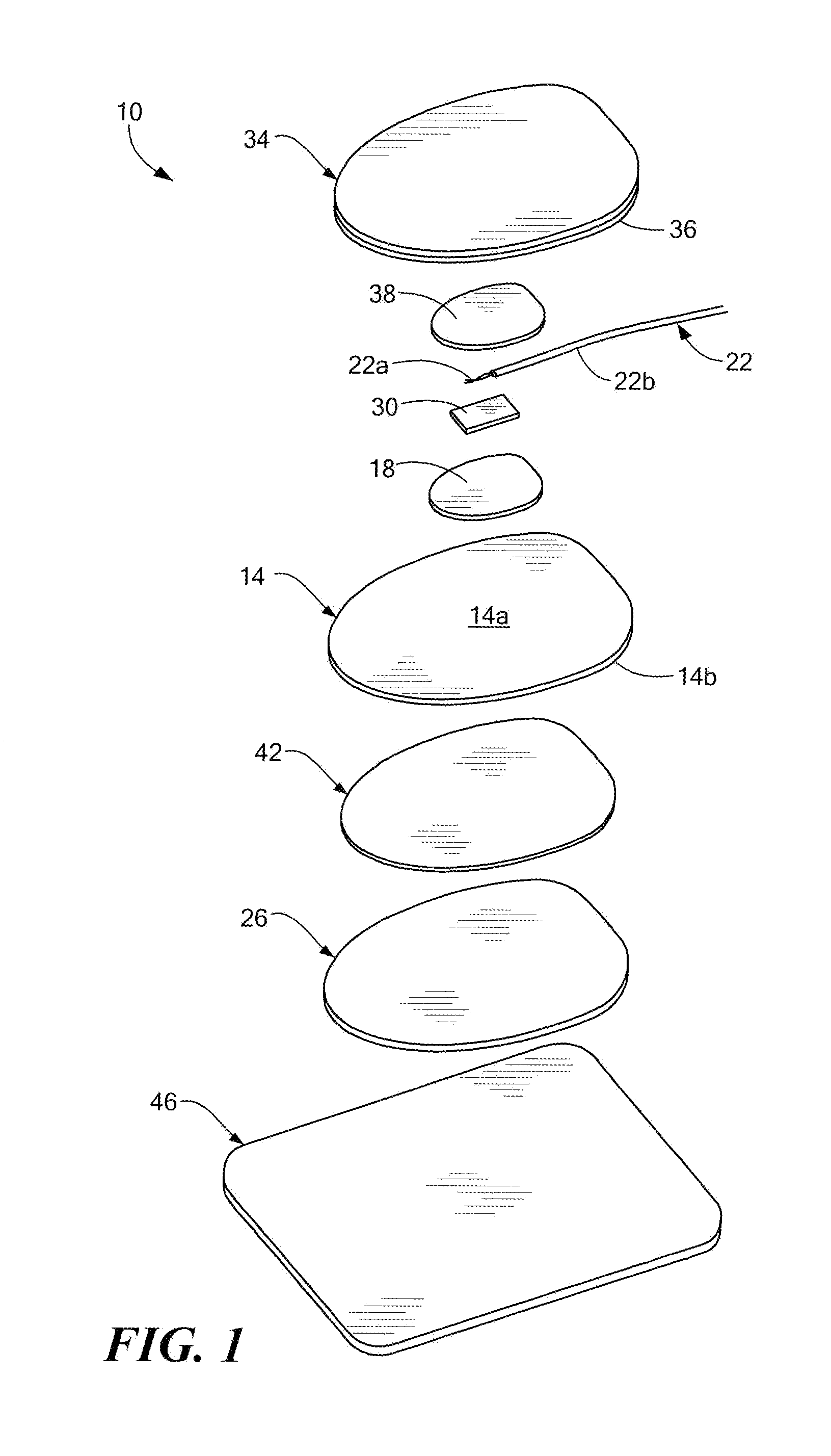

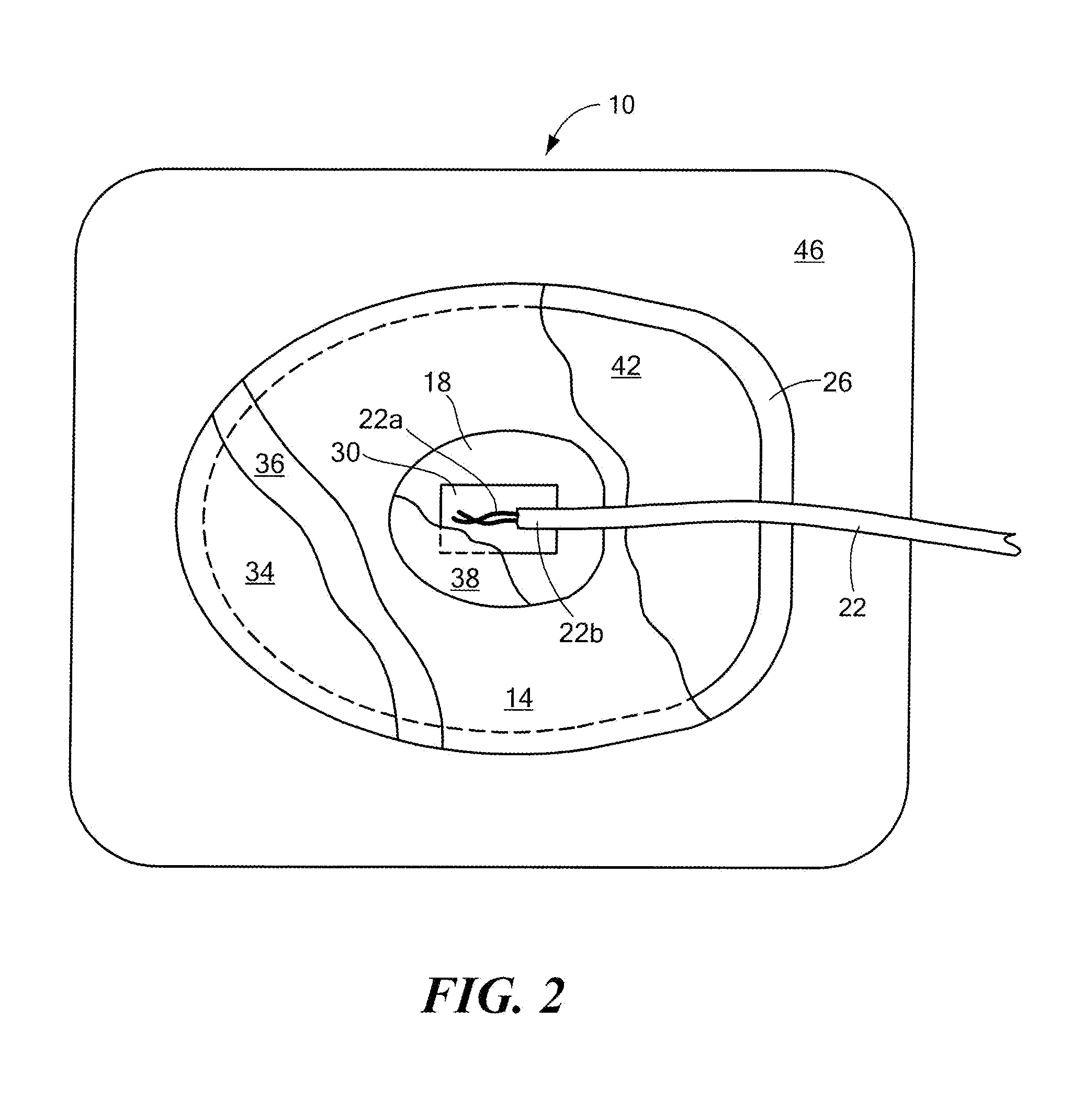

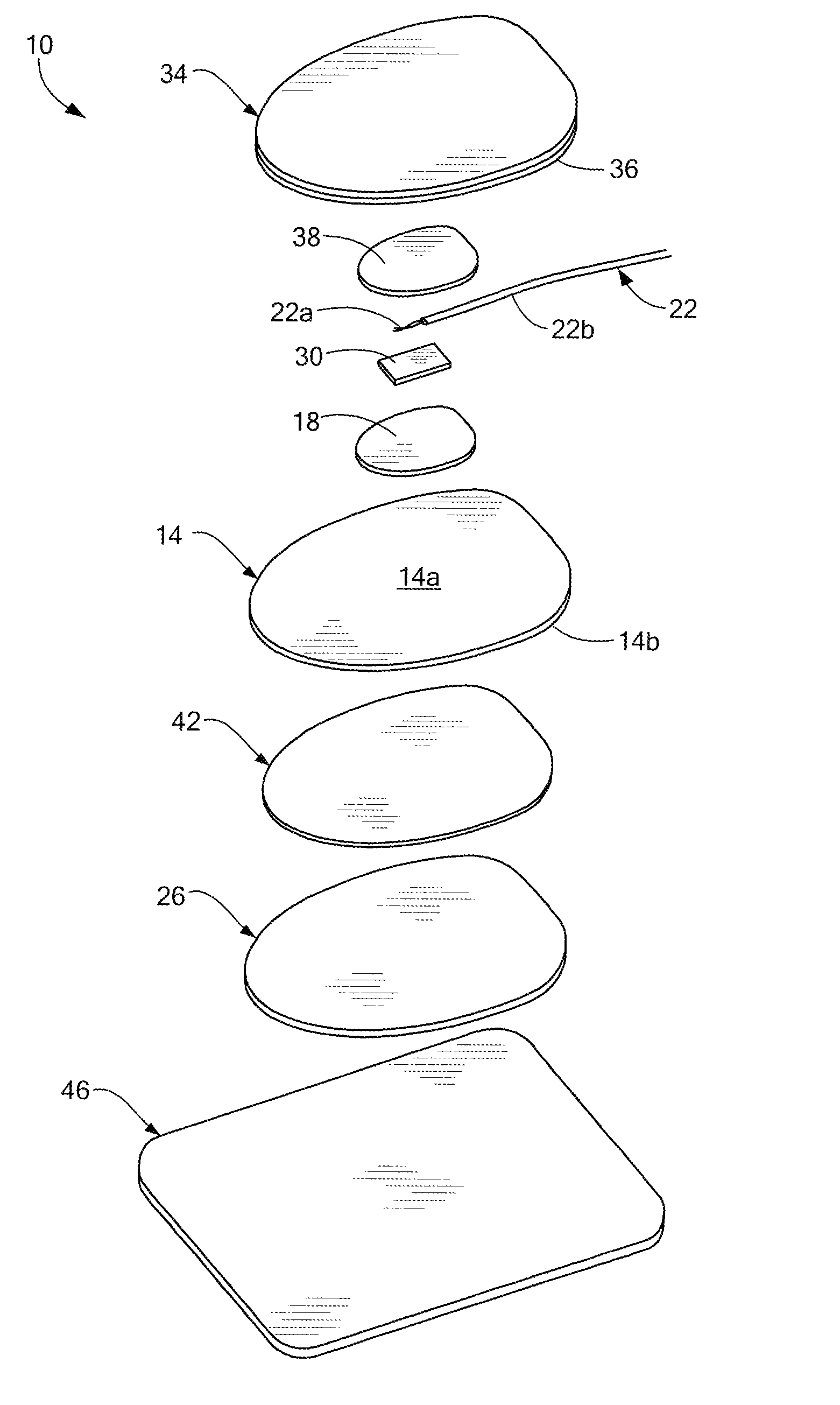

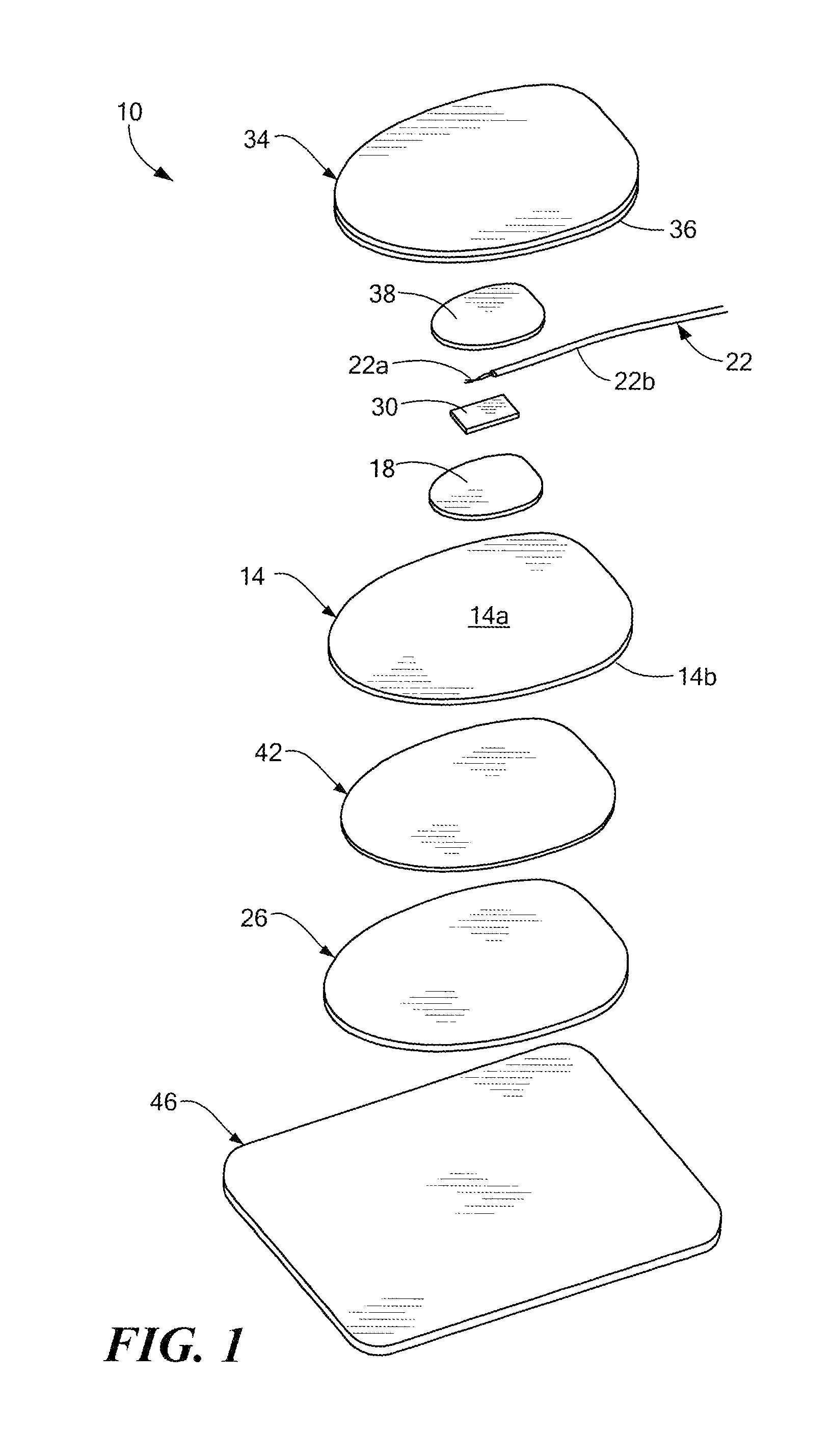

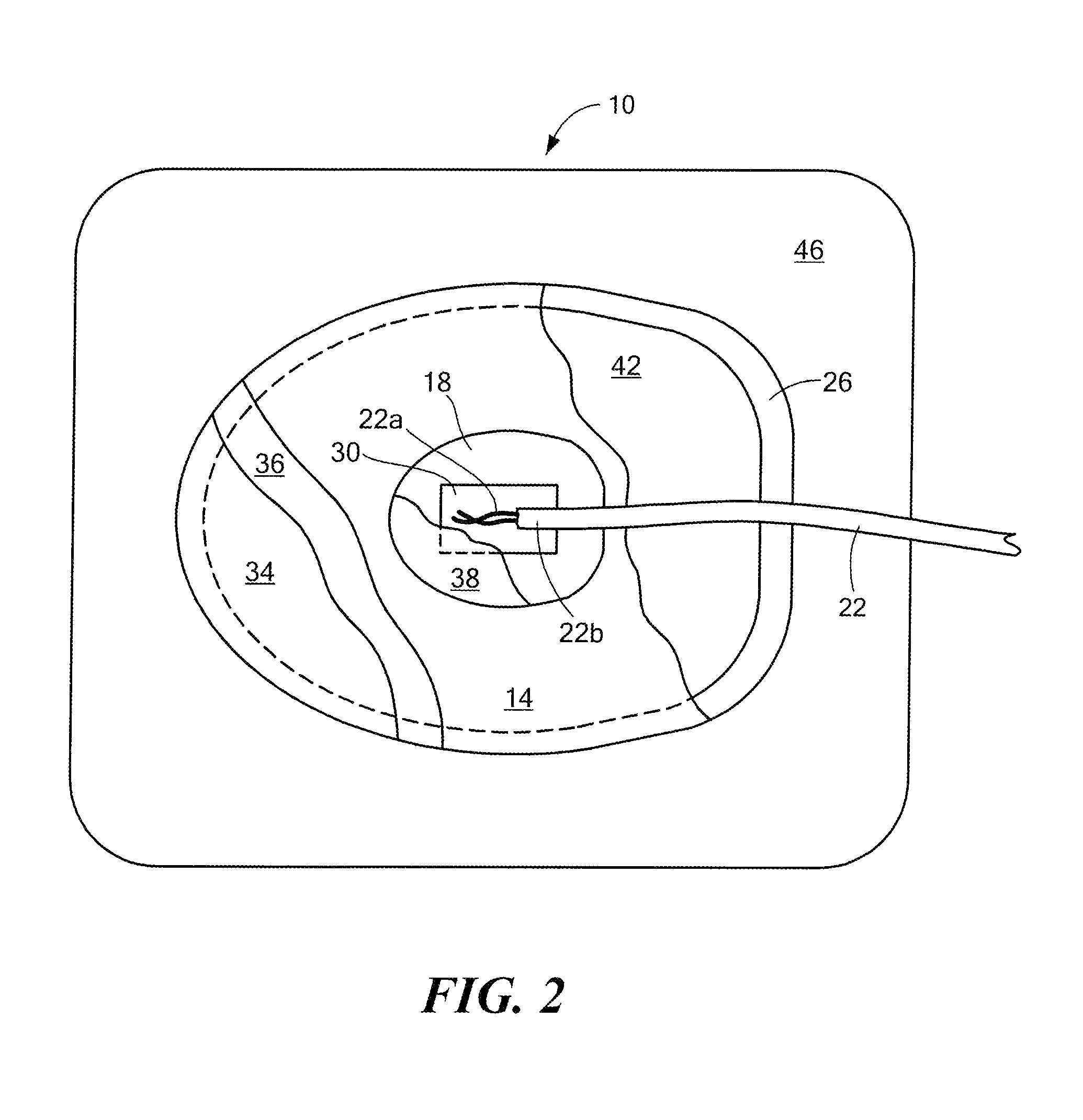

Apparatus and method for energy distribution in a medical electrode

ActiveUS20140073896A1Inhibit transferIncrease contact areaLine/current collector detailsBioelectric signal measurementPower flowElectrical conductor

A medical electrode includes an electrode member having a top face and a bottom face, an electrical conductor having an unfanned, unsheathed end portion for conducting energy between the electrode member and a medical device, and a patient contacting layer secured to at least a portion of the bottom face of the electrode member. An energy blocking layer is disposed between the unfanned conductor end portion and the electrode member to prevent immediate transfer of energy to the electrode member. A current distributing structure is described to conduct and distribute energy to the electrode member.

Owner:KPR U S LLC

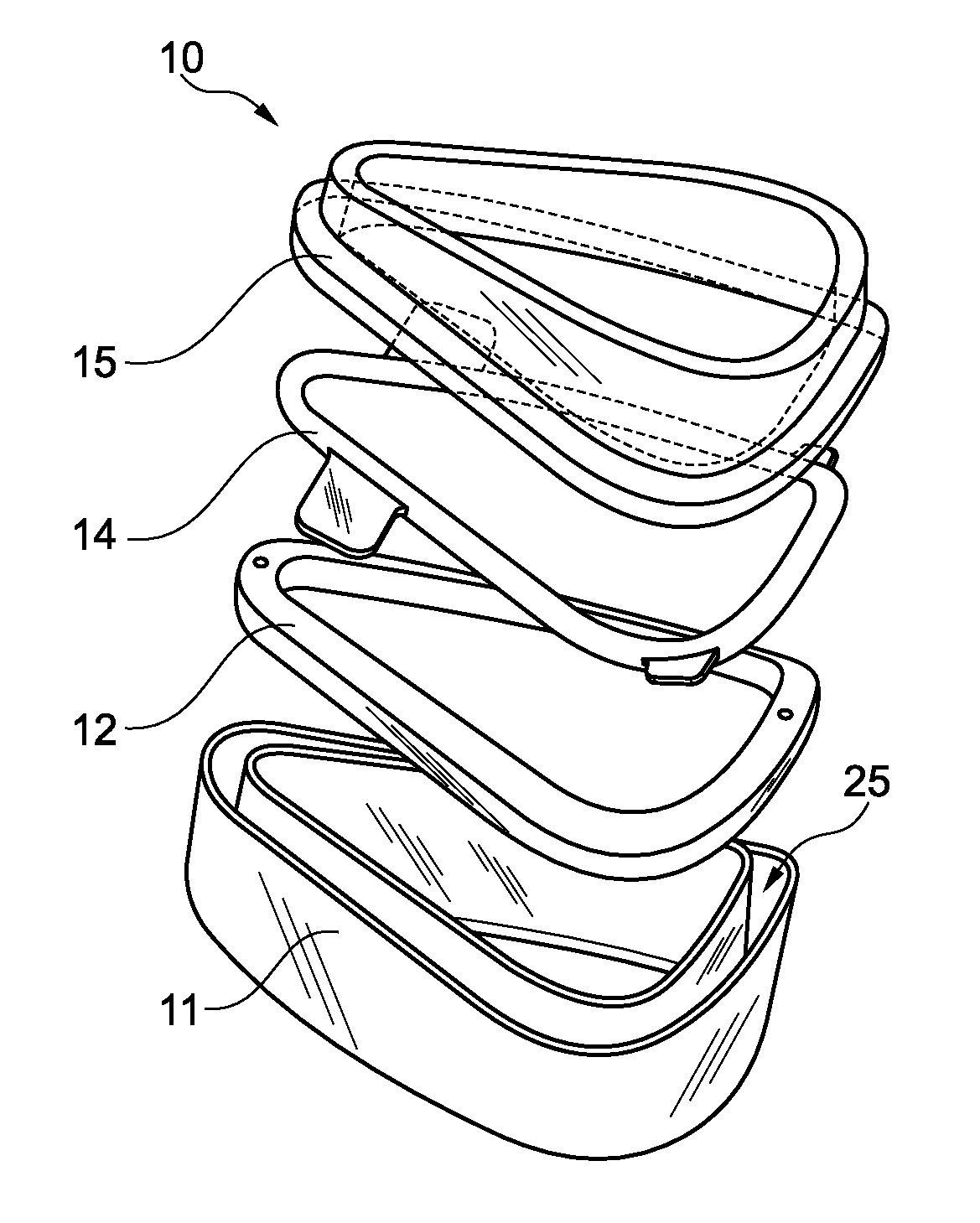

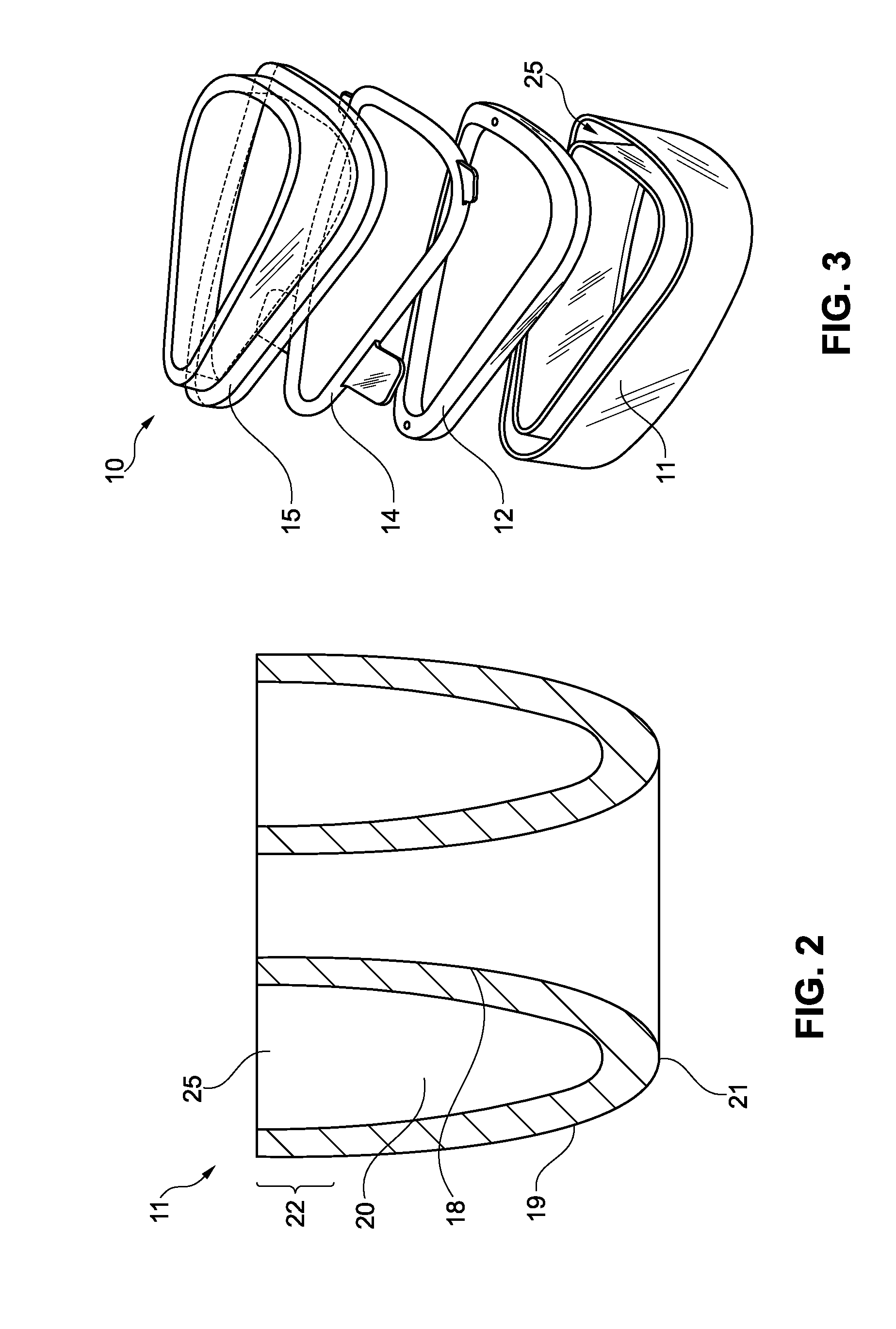

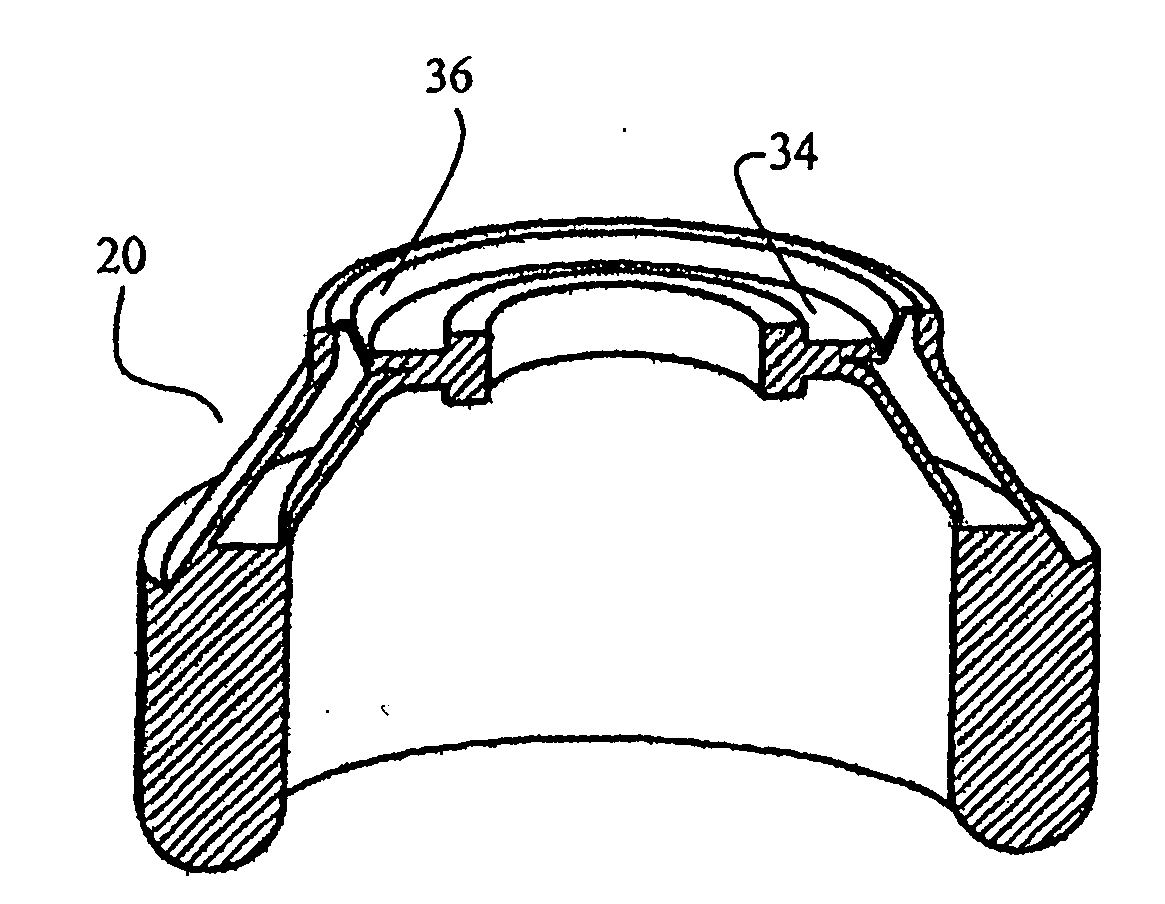

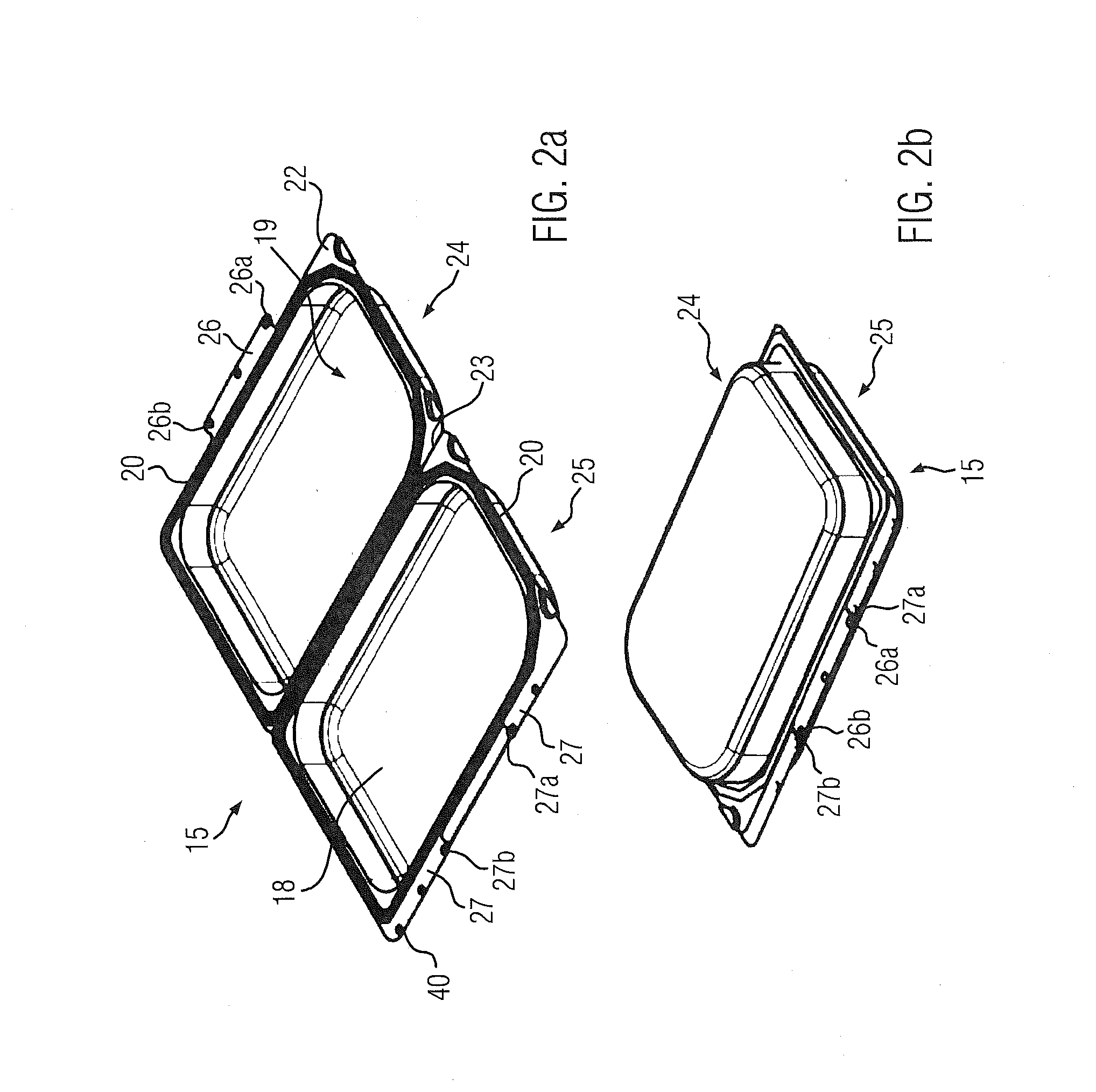

Filled hollow structure and method/tool for manufacturing same

ActiveUS20130139824A1Easily and efficiently carry-outEasy to optimizeMouldsRespiratory masksMaterials science

Owner:RESMED LTD

Battery pack and battery module and method for operating a battery module

ActiveUS7807289B2Shorten cycle timePreparation automationPrimary cell to battery groupingCells structural combinationLithiumCell bodies

A battery pack with at least two electrochemical cells, lithium ion cells in particular, has each cell including a positive pole and a negative pole on the end face of the particular cell body, the poles of the cells being electrically connected in series and / or in parallel. A cell connector for electrically connecting the cells is provided on at least two cells, on the end face on the same side relative to their position in the battery pack, the cell connector connecting one pole of the connected cells and extending to a contact region of a circuit board; the cell bodies of the cells are positioned parallel to each other, and the end faces of the cell bodies are located in the same plane.

Owner:ROBERT BOSCH GMBH

Apparatus and method for energy distribution in a medical electrode

ActiveUS8965534B2Inhibit transferIncrease contact areaElectrocardiographyHeart stimulatorsElectrical conductorDistributed structure

Owner:KPR U S LLC

Hollow structure and method/tool for manufacturing same

ActiveUS20100101581A1Easily and efficiently carry-outEasy to optimizeBreathing masksLayered productsEngineering

Owner:RESMED LTD

Current measurement using inductor coil with compact configuration and low TCR alloys

ActiveUS7667565B2Simple manufacturing processIncreased form factorTransformers/inductances detailsInductance with magnetic coreElectrical resistance and conductanceAlloy

This invention discloses an inductor that includes a conducting wire composed of an alloy having temperature coefficients of resistance (TCR) 700 ppm / ° C. or lower. The inductive coil has a winding configuration provided for enclosure in a substantially rectangular box with a mid-plane extended along an elongated direction of the rectangular box wherein the conducting wire intersecting at least twice near said mid-plane.

Owner:CYNTEC

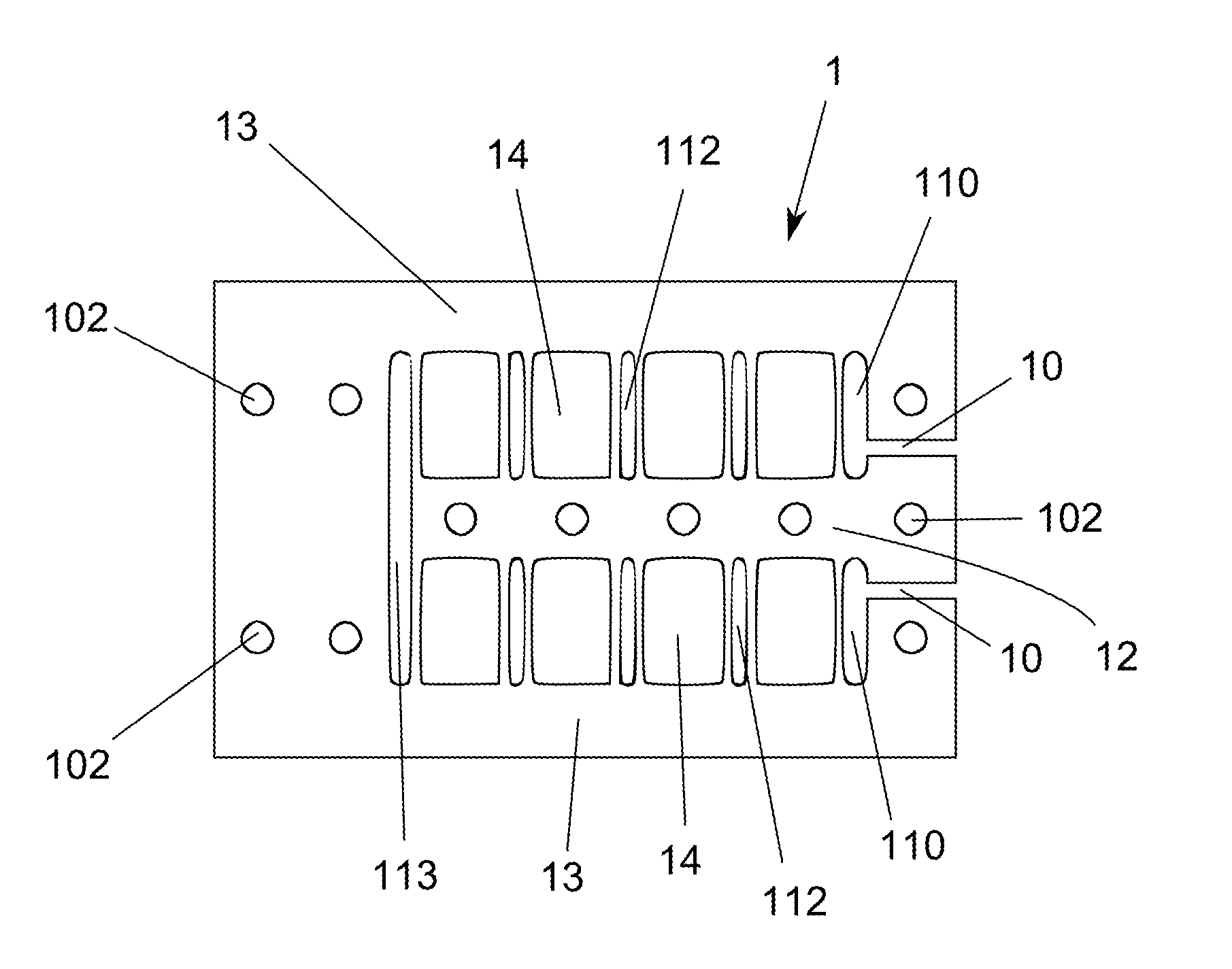

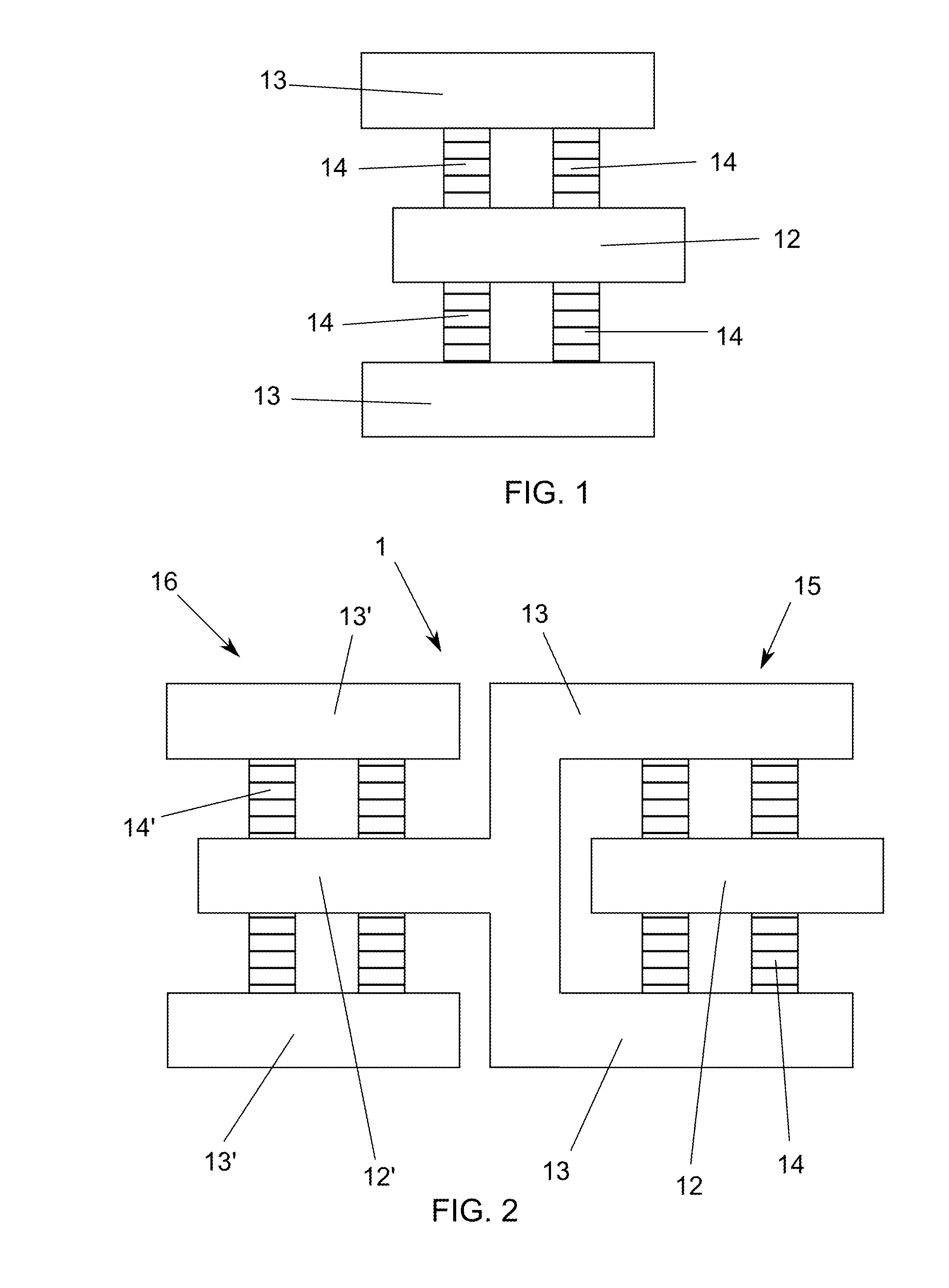

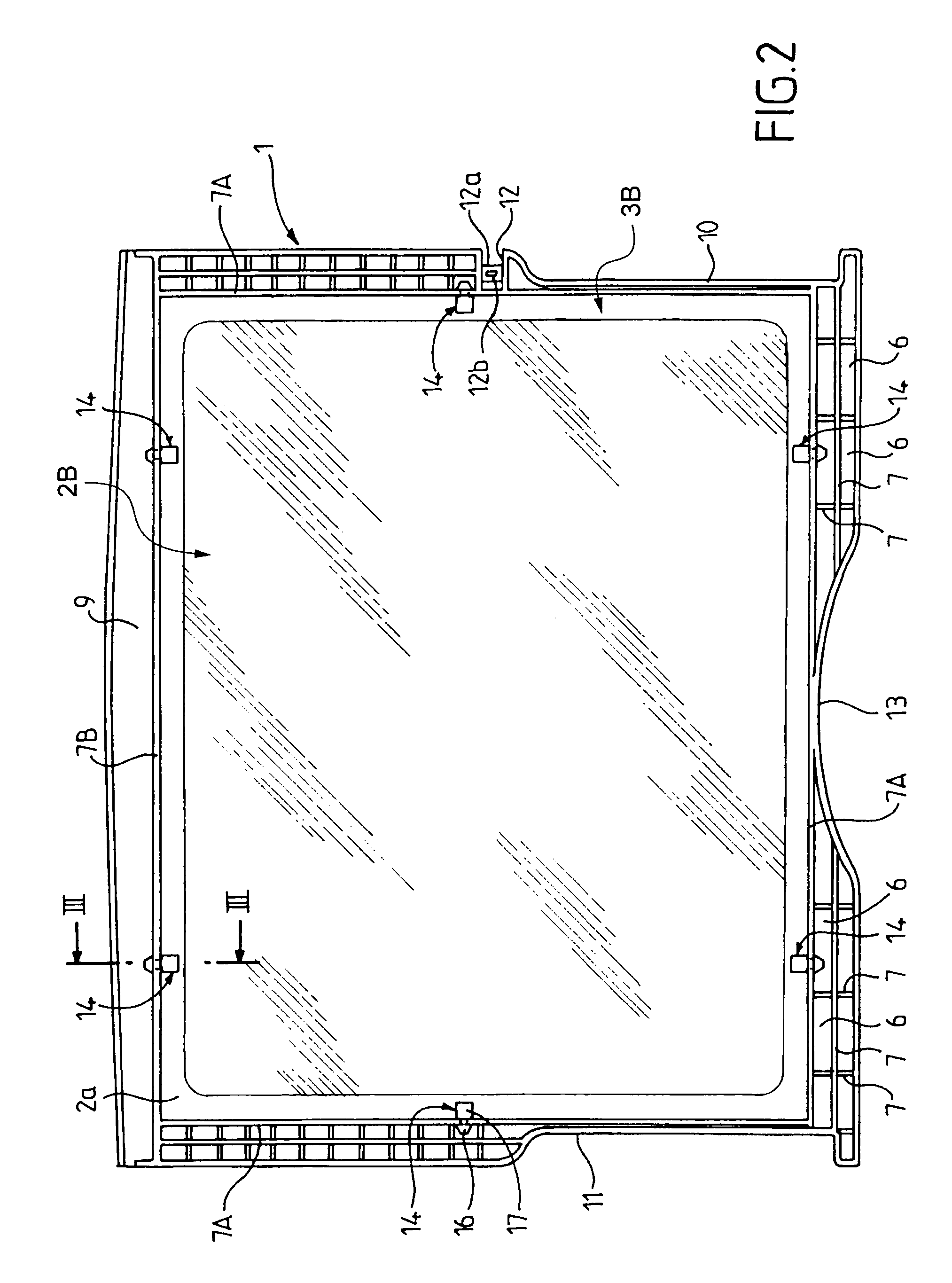

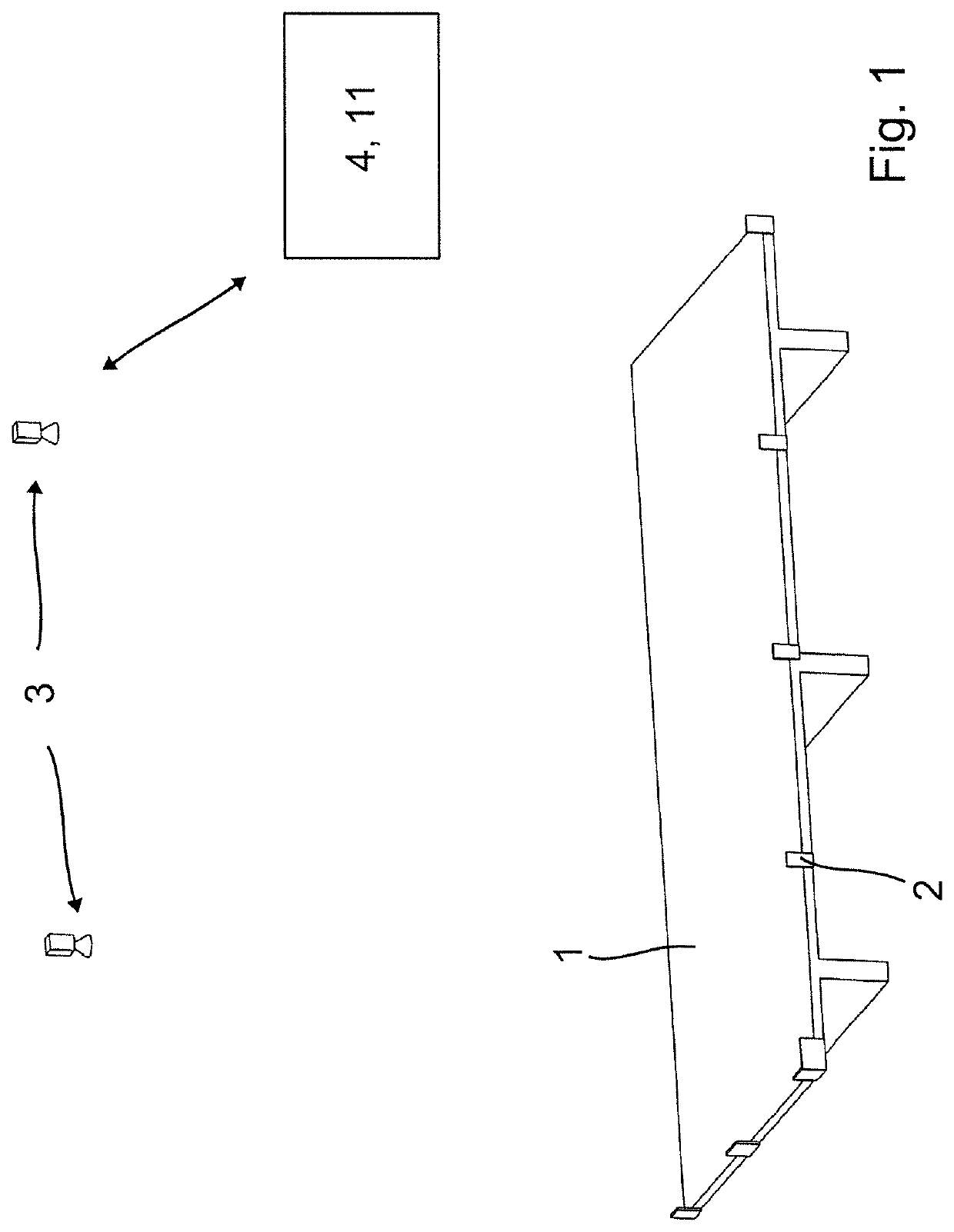

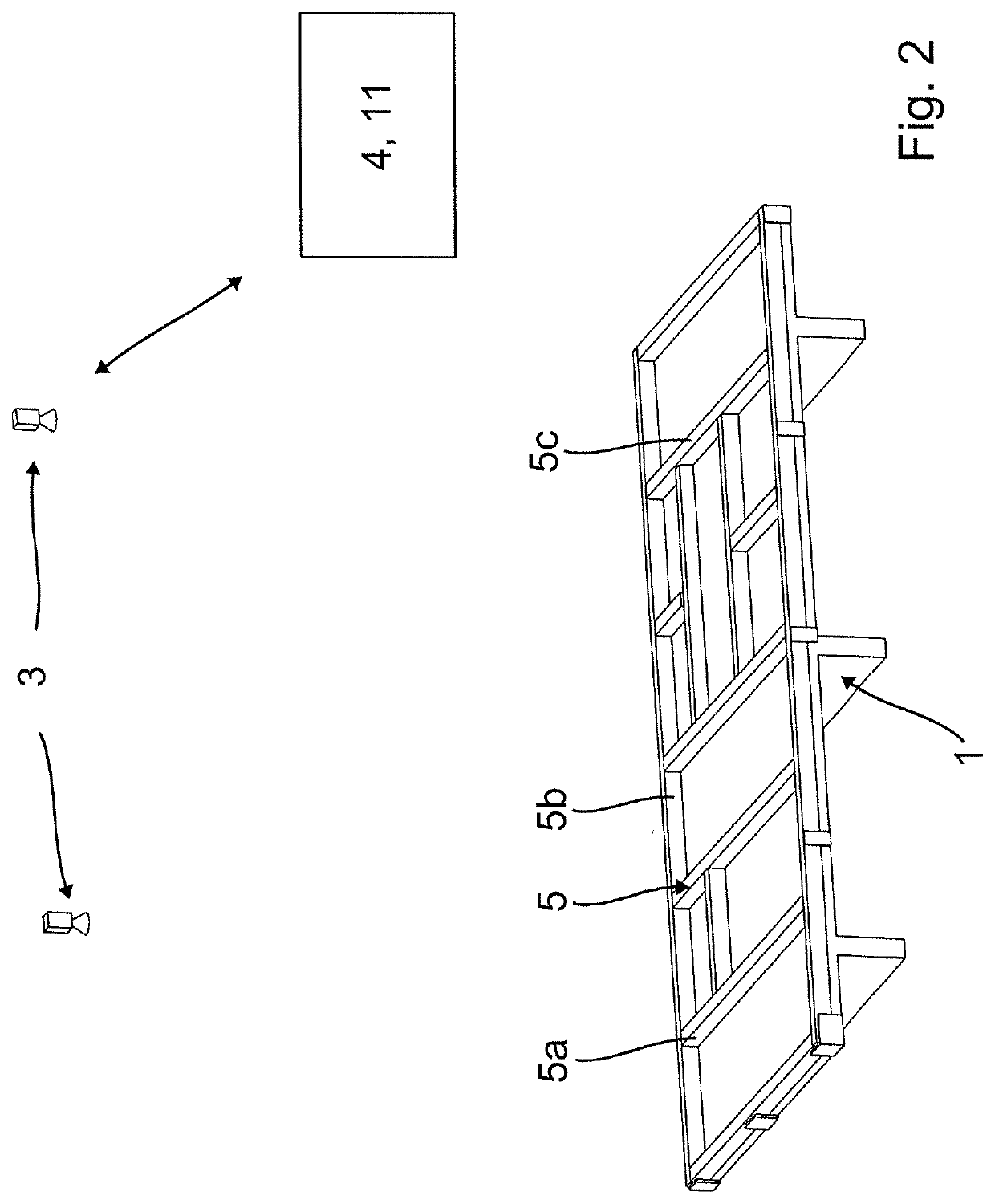

Modular Energy Dissipation System

InactiveUS20110031080A1Easy to adaptPreparation automationProtective buildings/sheltersElastic dampersDissipative systemComputer module

Modular energy dissipation system for linking two structures in a linking direction, comprising a yielding energy dissipator (1) provided with at least two energy dissipation modules (15, 16) successively arranged along said linking direction, each module comprising a central strip (12; 12′), two sidelong strips (13; 13′) and a plurality of yielding elements (14; 14′) between the central strip and the sidelong strips, so that the central strip of a module located at one end of the dissipator is linked to one of the structures and the sidelong strips of this module are integrated with the central strip of the adjacent module, and the sidelong strips of the module located at the other end of the dissipator are linked to the other structure and the central strip of this module is integrated with the sidelong strips of the adjacent module.

Owner:UNIV DE GIRONA

Lacquer Composition and Use Thereof

ActiveUS20120034458A1Improve propertiesImprove corrosion resistanceLamination ancillary operationsNon-macromolecular adhesive additivesElastomerLacquer

The present invention relates to a lacquer composition, particularly an adhesive and corrosion-protective lacquer for rare earth magnets, on the basis of an epoxy resin mixture, a setting accelerator, a silane-based epoxy functional adhesion promoter and a solvent or a solvent mixture, wherein the lacquer composition includes 5 to 20 wt. %, with respect to the amount of solid resin in the base of the epoxy resin mixture, of a highly viscous epoxy resin based on bisphenol-A with an elastomer content of more than 30 wt. %.

Owner:VACUUMSCHMELZE GMBH & CO KG

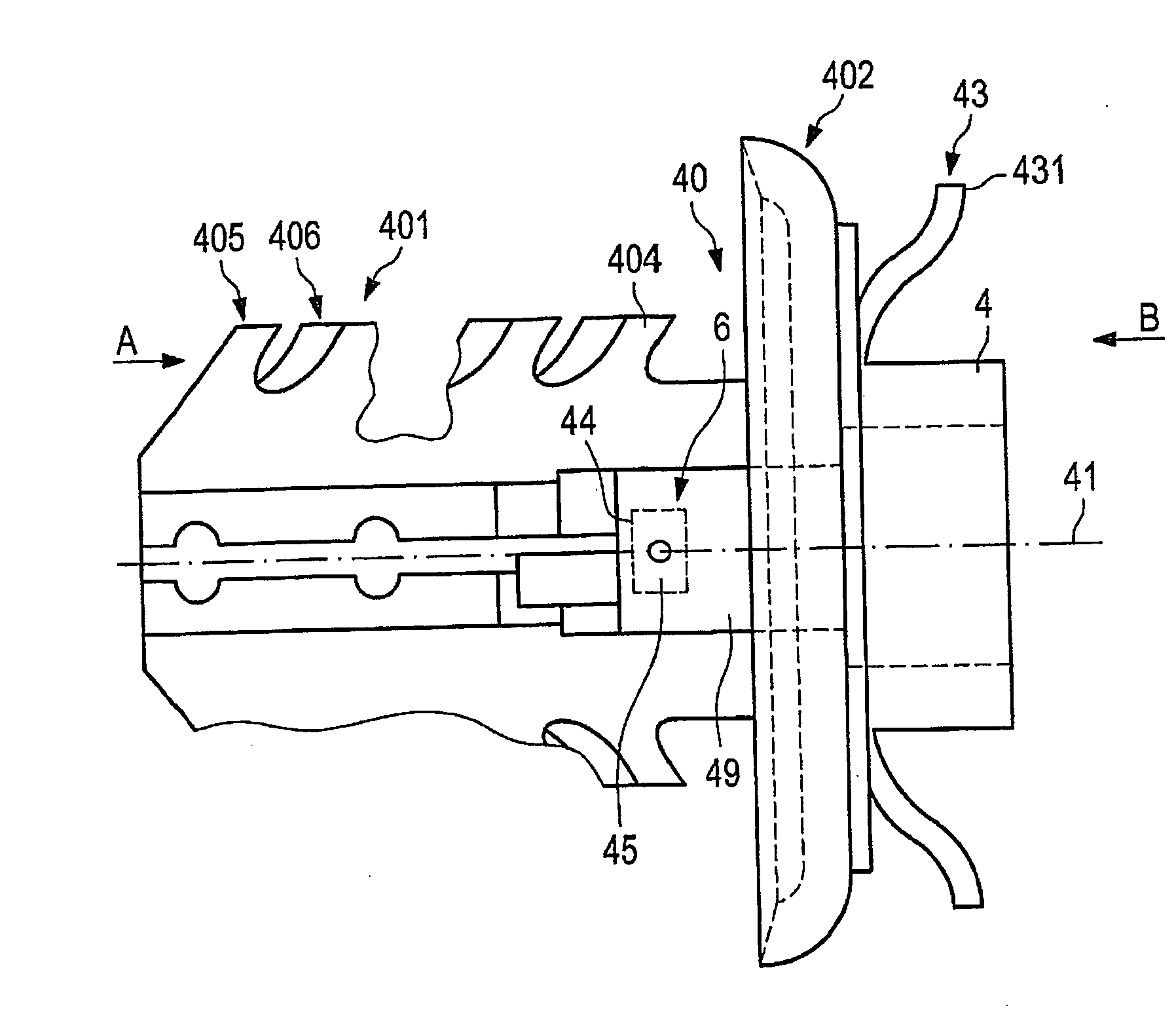

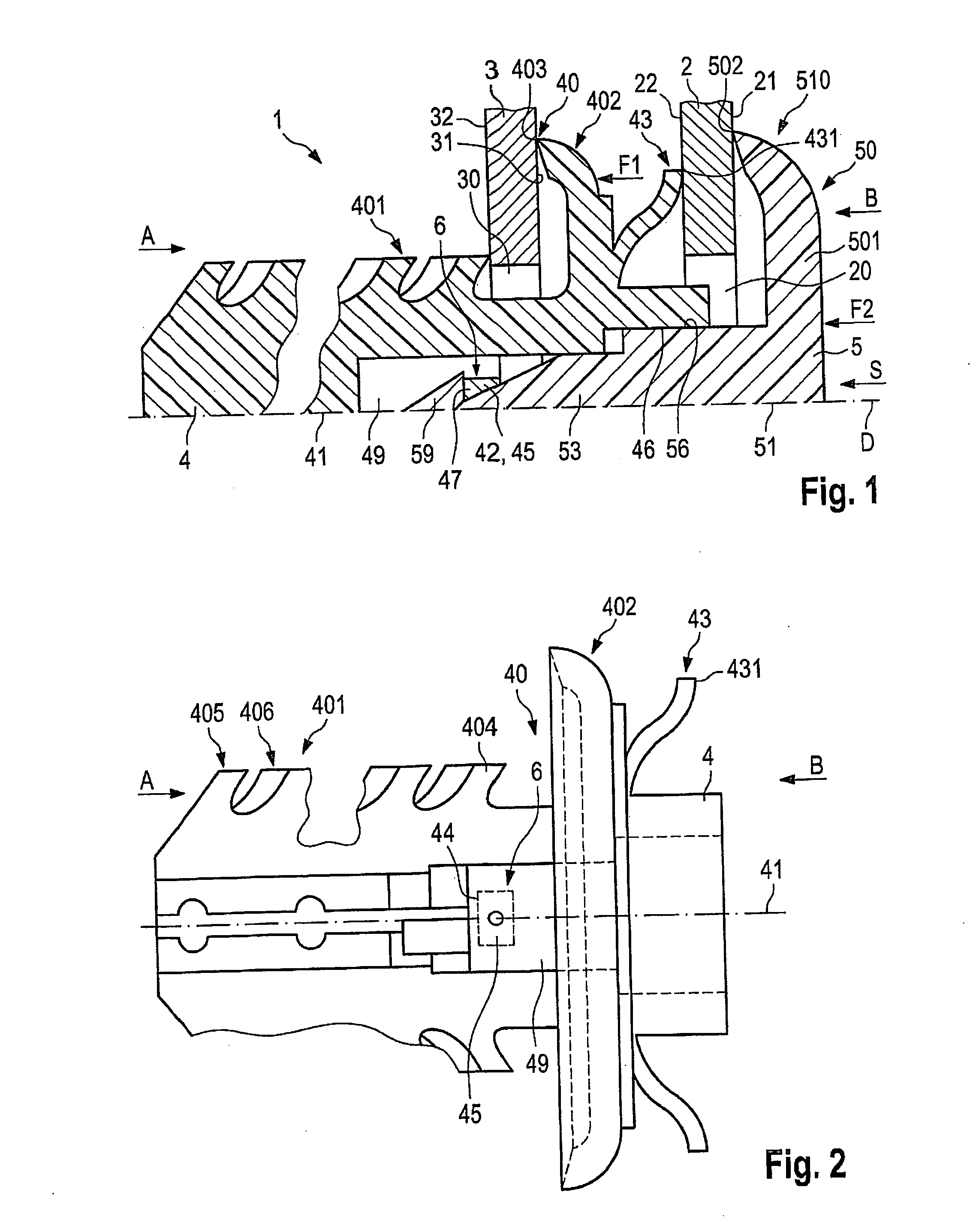

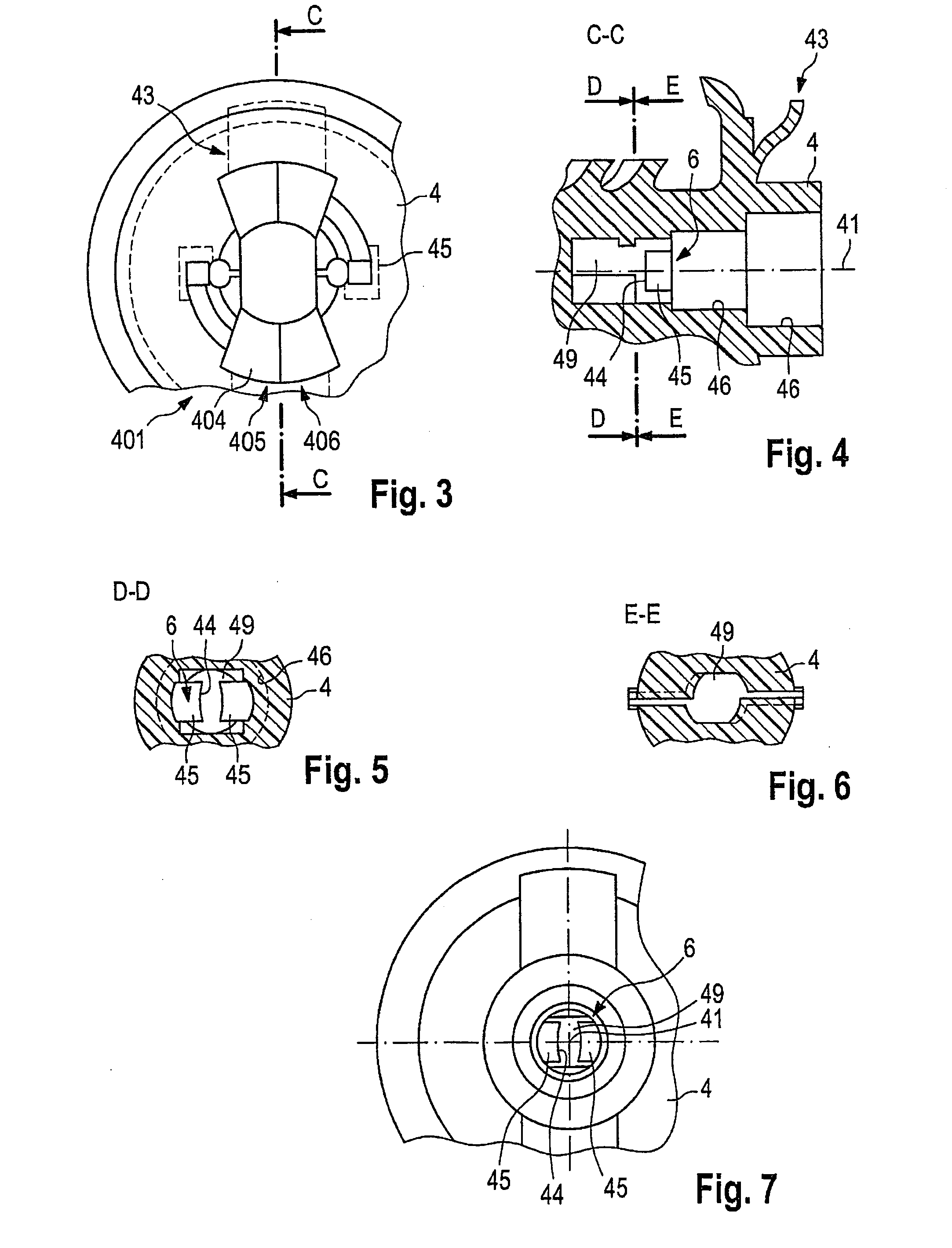

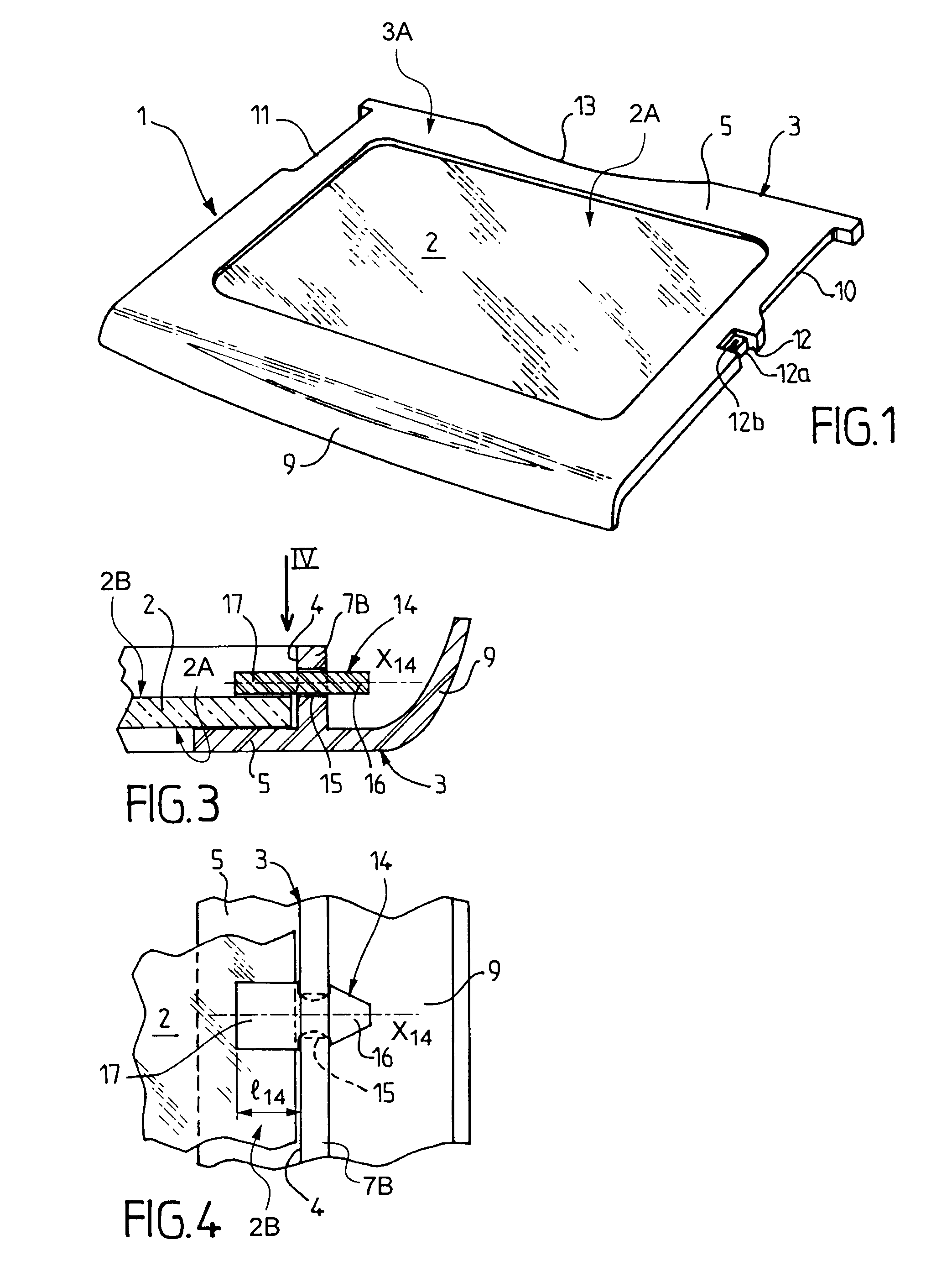

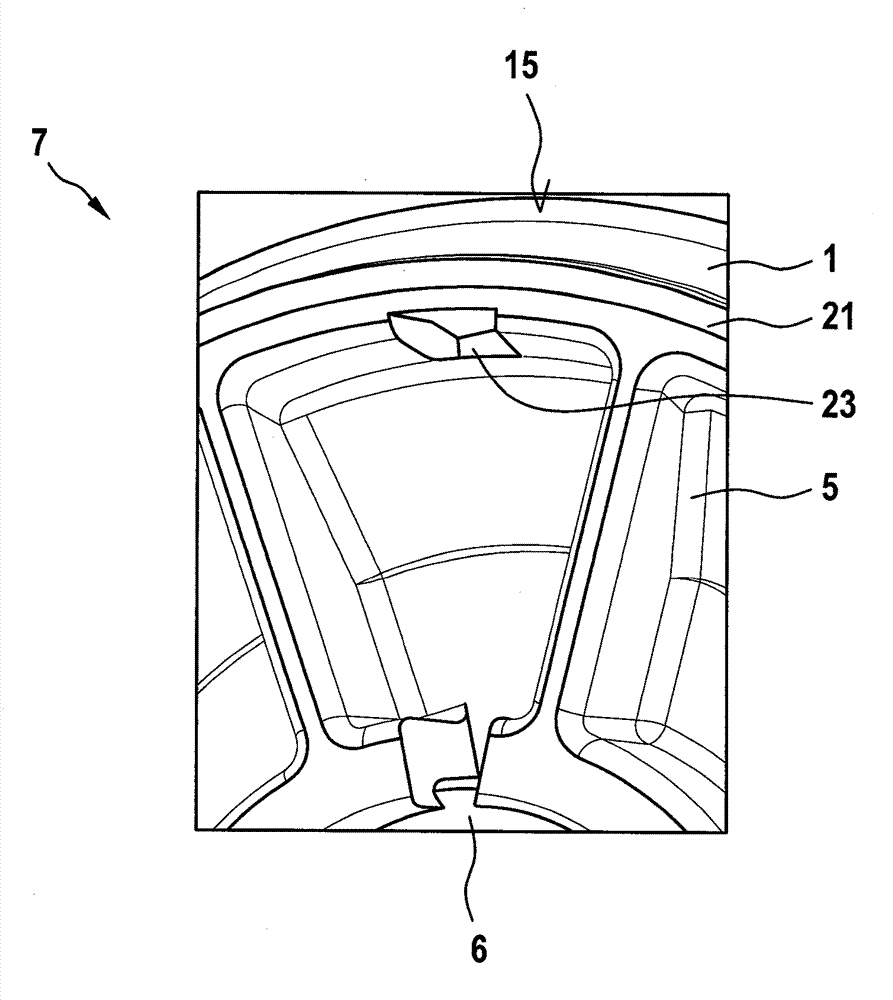

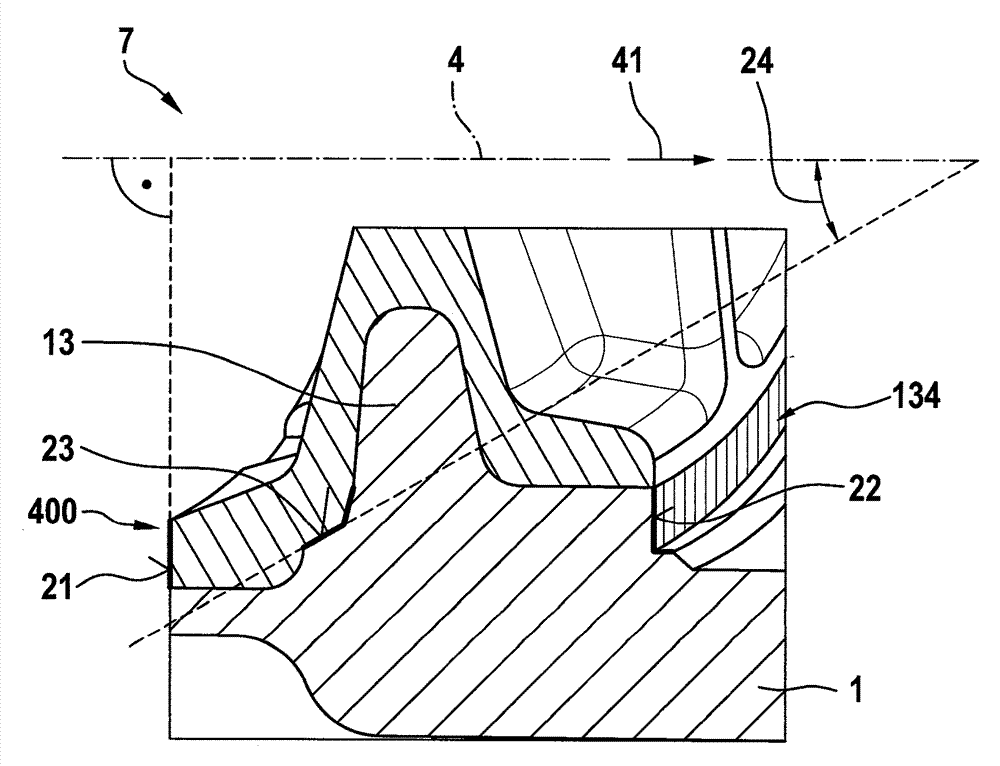

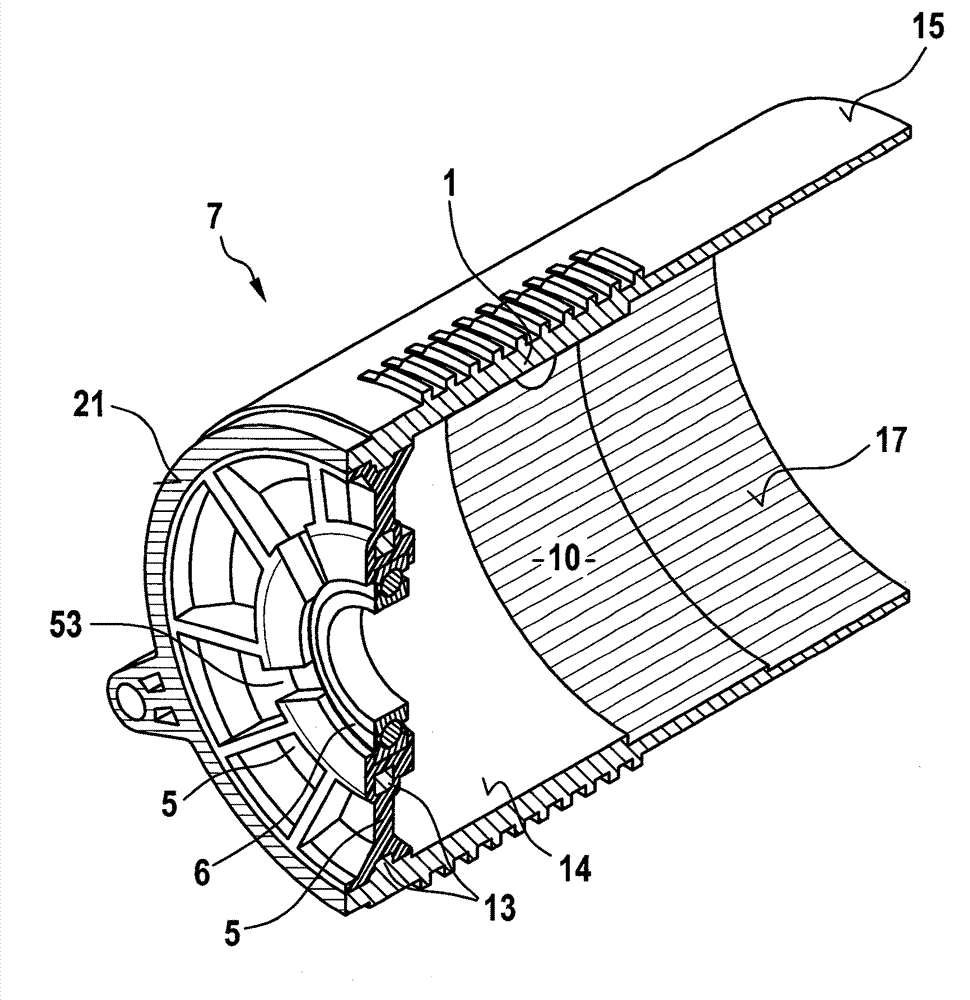

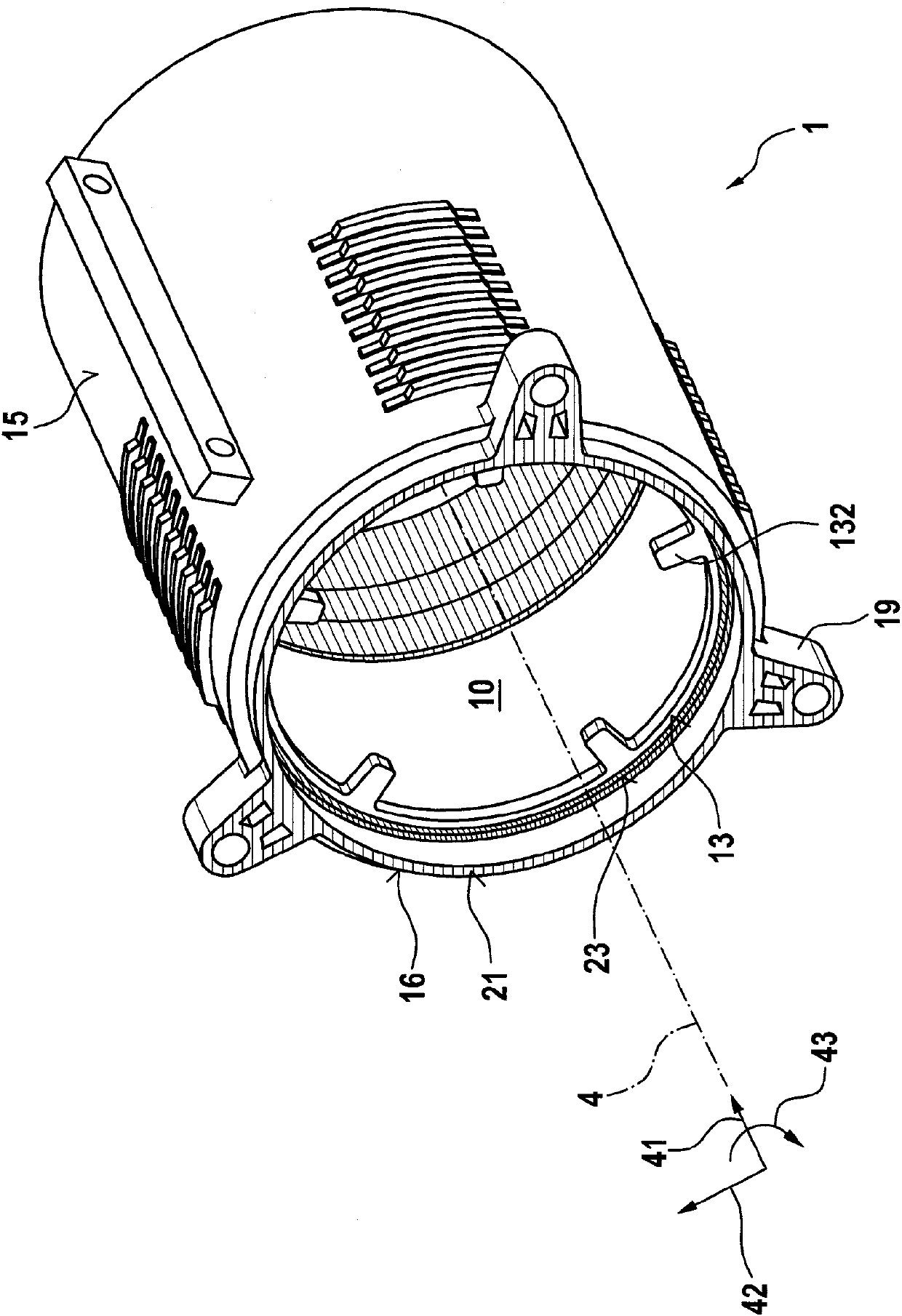

Connecting assembly for fastening an add-on element on a carrier element

A connecting assembly (1) for fastening an add-on element (2) on a carrier element (3) includes a foot (4) which can be inserted into an opening (39) of the carrier element (3) and has fixing means (40) for fixing the foot (4) with respect to the carrier element (3) in a direction parallel to the longitudinal axis (41) of the foot (4). The connecting assembly (1) further includes a pin (5) which can be inserted into a passage (20) of the add-on element (2) and has retaining means (50) which counteract a displacement of the add-on element (2) in a direction parallel to the longitudinal axis (51) of the pin (5). The pin (5) is adapted to be inserted into the foot (4) and has locking means (52) which cooperate with complementary locking means (42) of the foot (4) in a radial direction with -respect to the longitudinal axes (41, 51). The foot (4) has two elastic axial restoring means (43) with respect to its longitudinal axis (41) which hold a support surface (54) of the pin (5) and a counter support surface (44) of the foot (4) in contact with each other when the locking means (52) of the pin (5) cooperate with the complementary locking means (42) of the foot (4) after the insertion of the pin (5) into the foot (4).

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

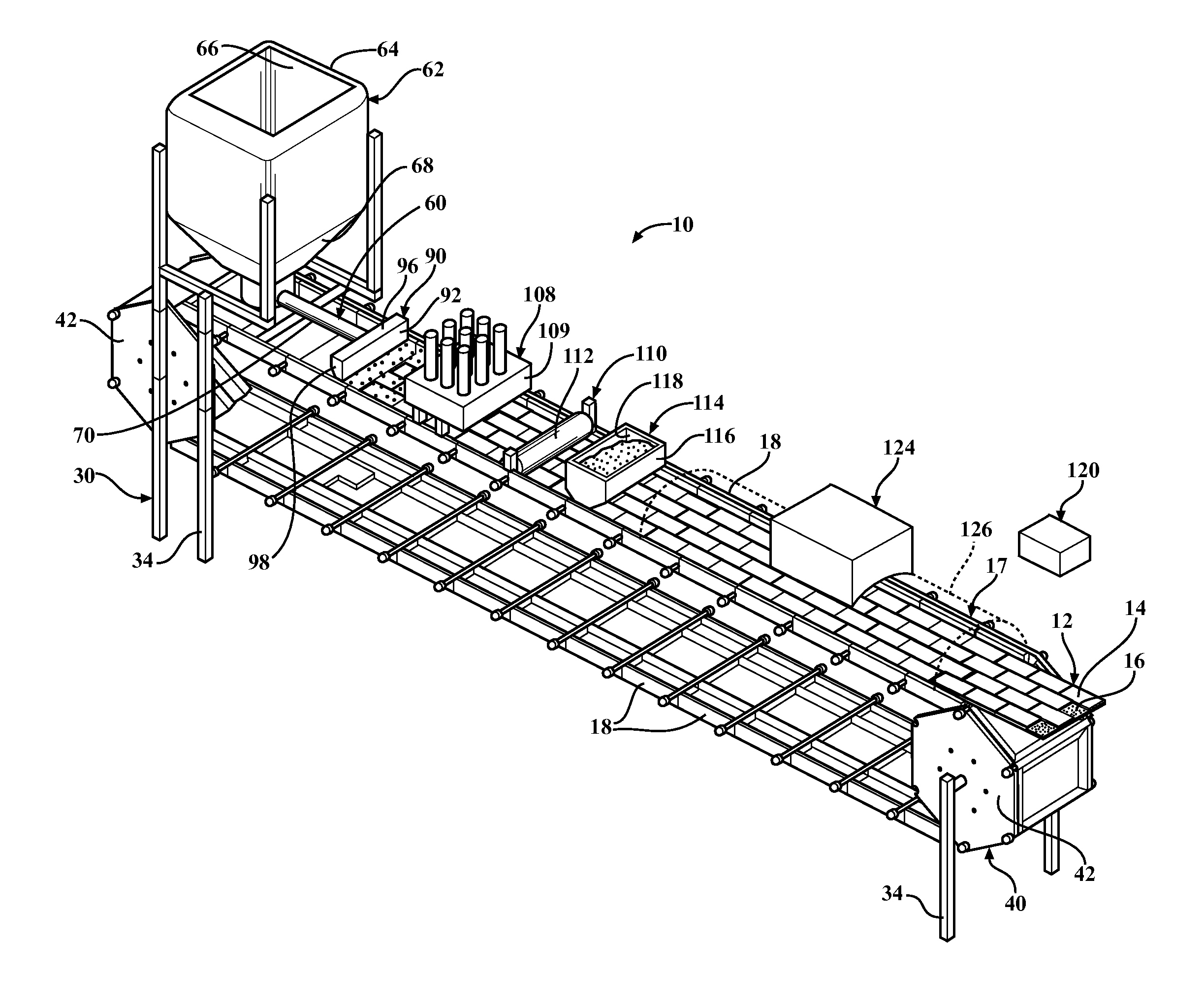

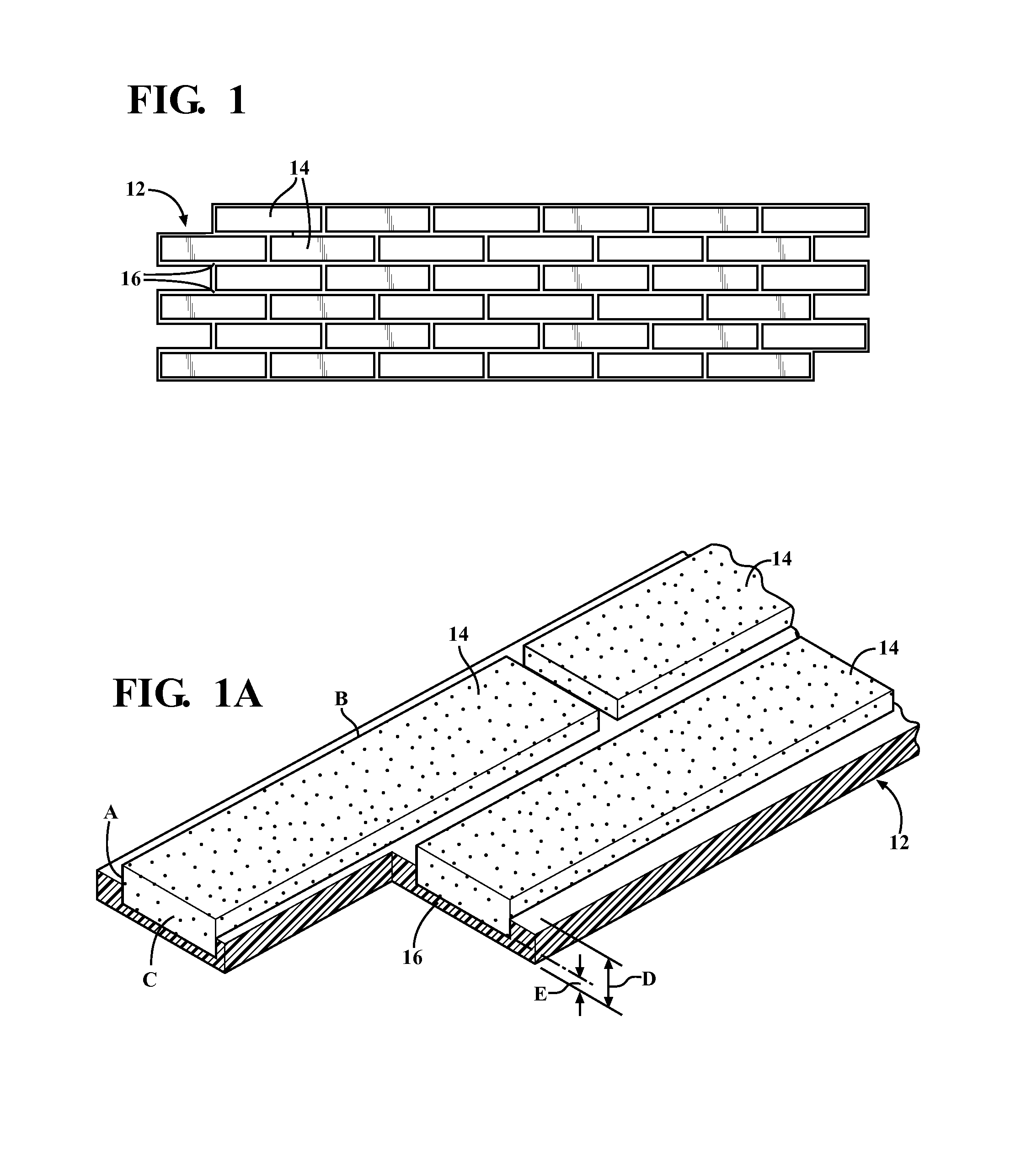

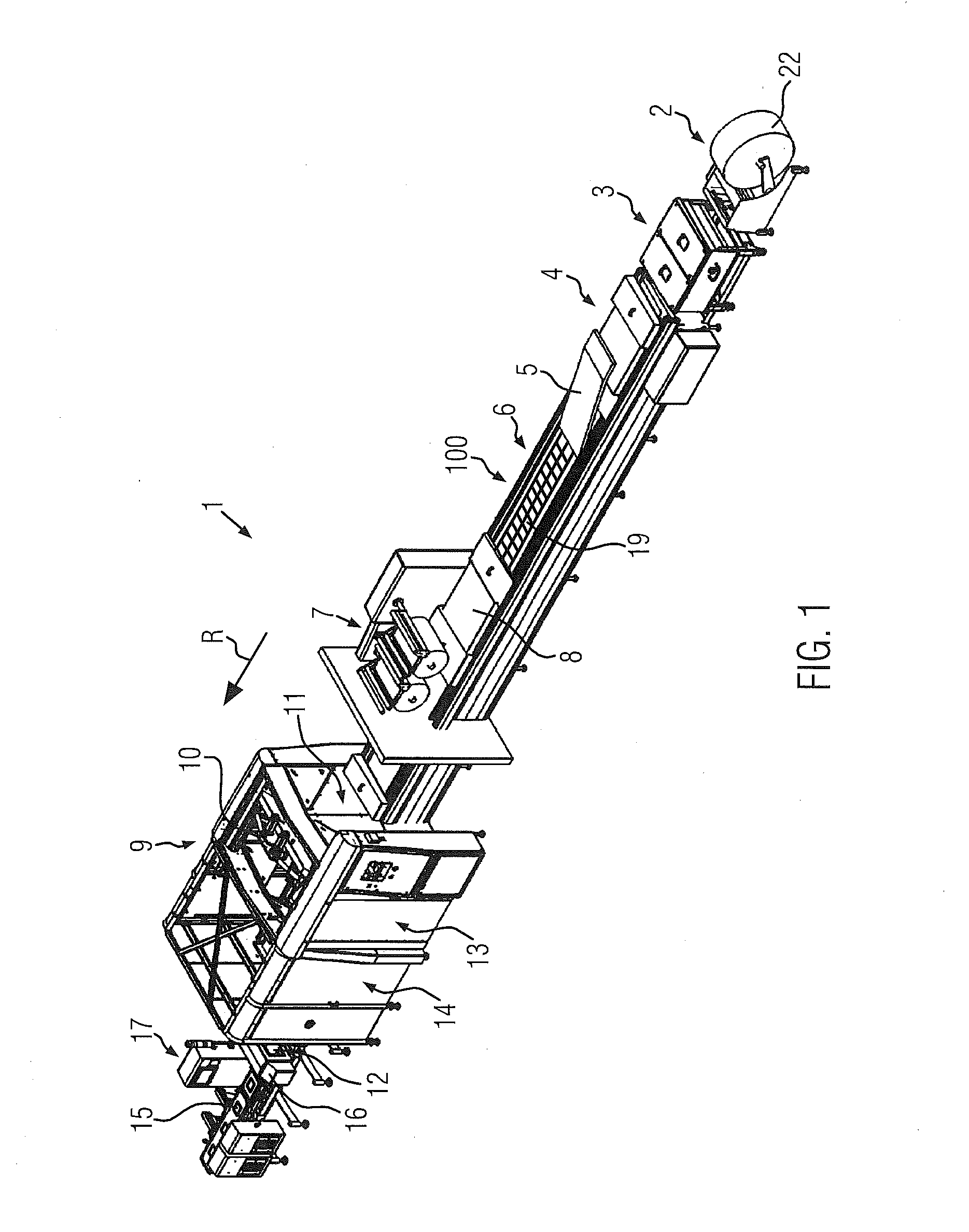

Machine for continuous casting of pre-mortared masonry panels

ActiveUS20140023741A1Obviates laborious needPreparation automationTailstocks/centresWallsBrickPanelling

A machine for continuous casting of pre-mortared masonry panels includes a rotatable continuous mold for continuously forming pre-mortared masonry panels and an application system for applying polymeric material to the continuous mold as the continuous mold rotates. The machine also includes a brick setter system for setting bricks onto the polymeric material as the continuous mold rotates. The machine further includes a cutting device for cutting the bricks and polymeric material into panels to form the pre-mortared masonry panels.

Owner:GRASSI FR +1

Packaging facility with latching station and method

InactiveUS20140250839A1Preparation automationKeep shelf lifeWrapper twisting/gatheringLidsEngineering

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Lacquer composition and use thereof

ActiveUS8717130B2Improve propertiesImprove corrosion resistancePermanent magnetsLaminationElastomerLacquer

The present invention relates to a lacquer composition, particularly an adhesive and corrosion-protective lacquer for rare earth magnets, on the basis of an epoxy resin mixture, a setting accelerator, a silane-based epoxy functional adhesion promoter and a solvent or a solvent mixture, wherein the lacquer composition includes 5 to 20 wt. %, with respect to the amount of solid resin in the base of the epoxy resin mixture, of a highly viscous epoxy resin based on bisphenol-A with an elastomer content of more than 30 wt. %.

Owner:VACUUMSCHMELZE GMBH & CO KG

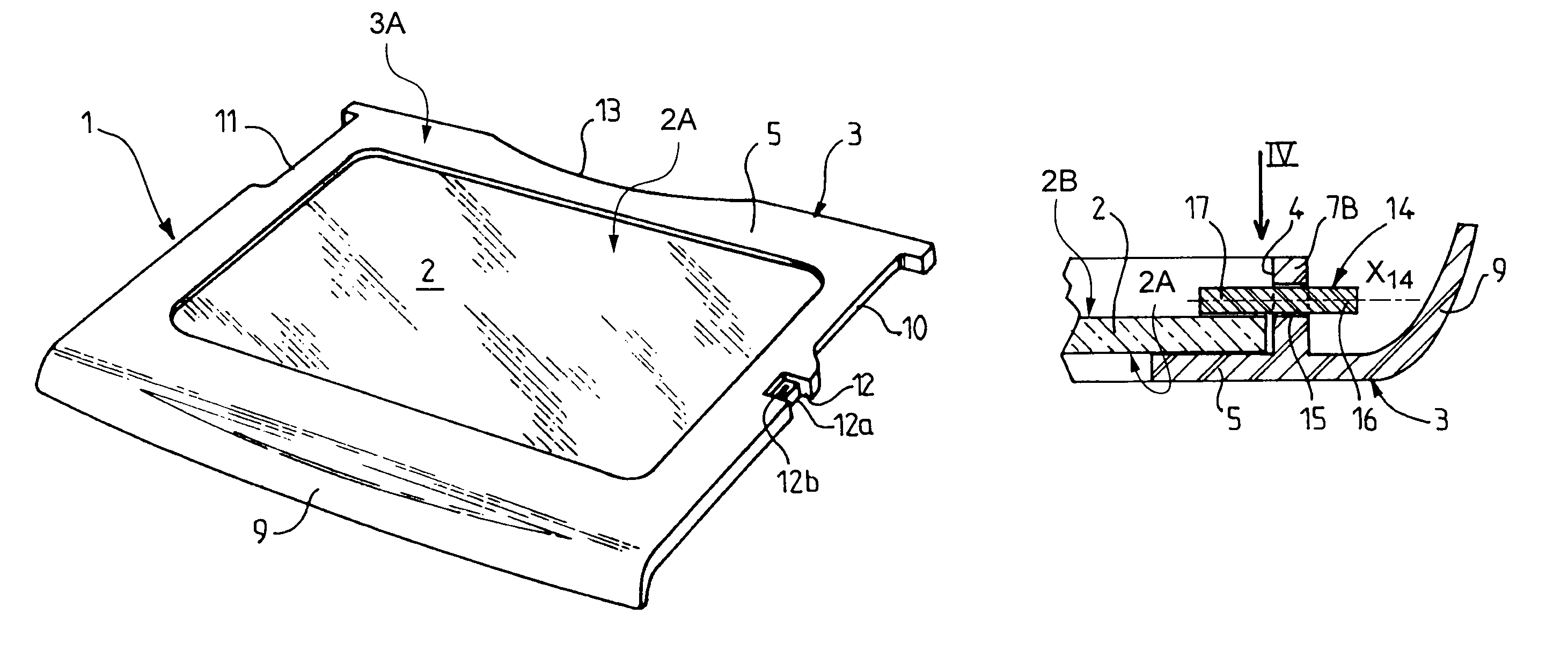

Shelf, in particular for refrigerated installations

InactiveUS8480194B2Simple manufacturing methodSimple methodShow cabinetsLighting and heating apparatusEngineeringRefrigerated temperature

A shelf for an item of furniture, especially for a refrigerator or the like, includes a panel for supporting articles and a frame capable of enclosing the panel by its actual surrounding part, the frame configured to allow the shelf to be fitted into the body of the furniture. The shelf further includes at least one retaining member for retaining the panel at its lower part, which retaining member can be inserted laterally into a hole made in a rib of the frame, which rib runs along the panel, being offset internally relative to the external peripheral edge of the frame, and extends beyond the panel, and then can be fastened onto or behind the border wall of the hole, the retaining member bearing, in the fastened position, against the panel.

Owner:SAINT-GOBAIN GLASS FRANCE

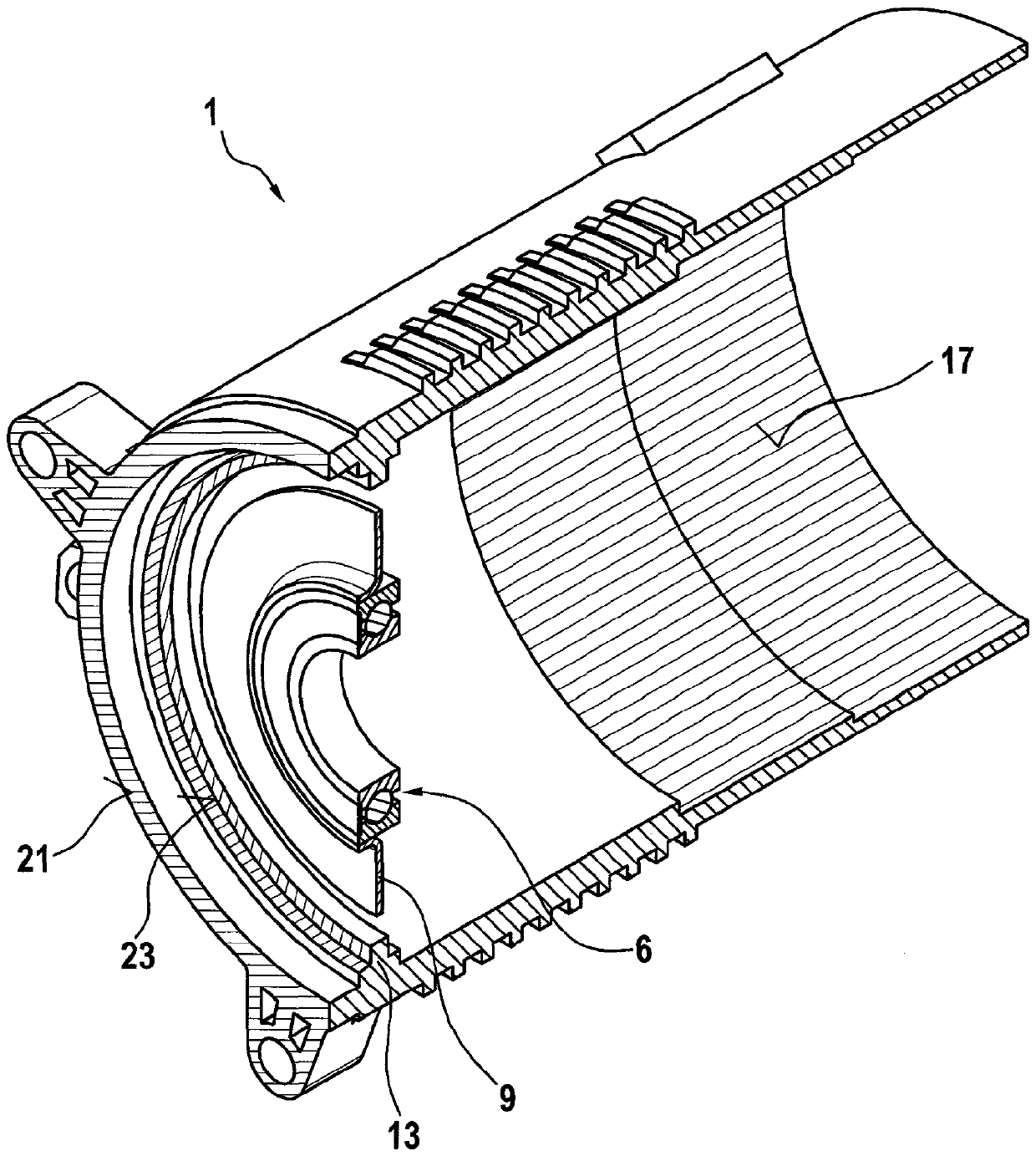

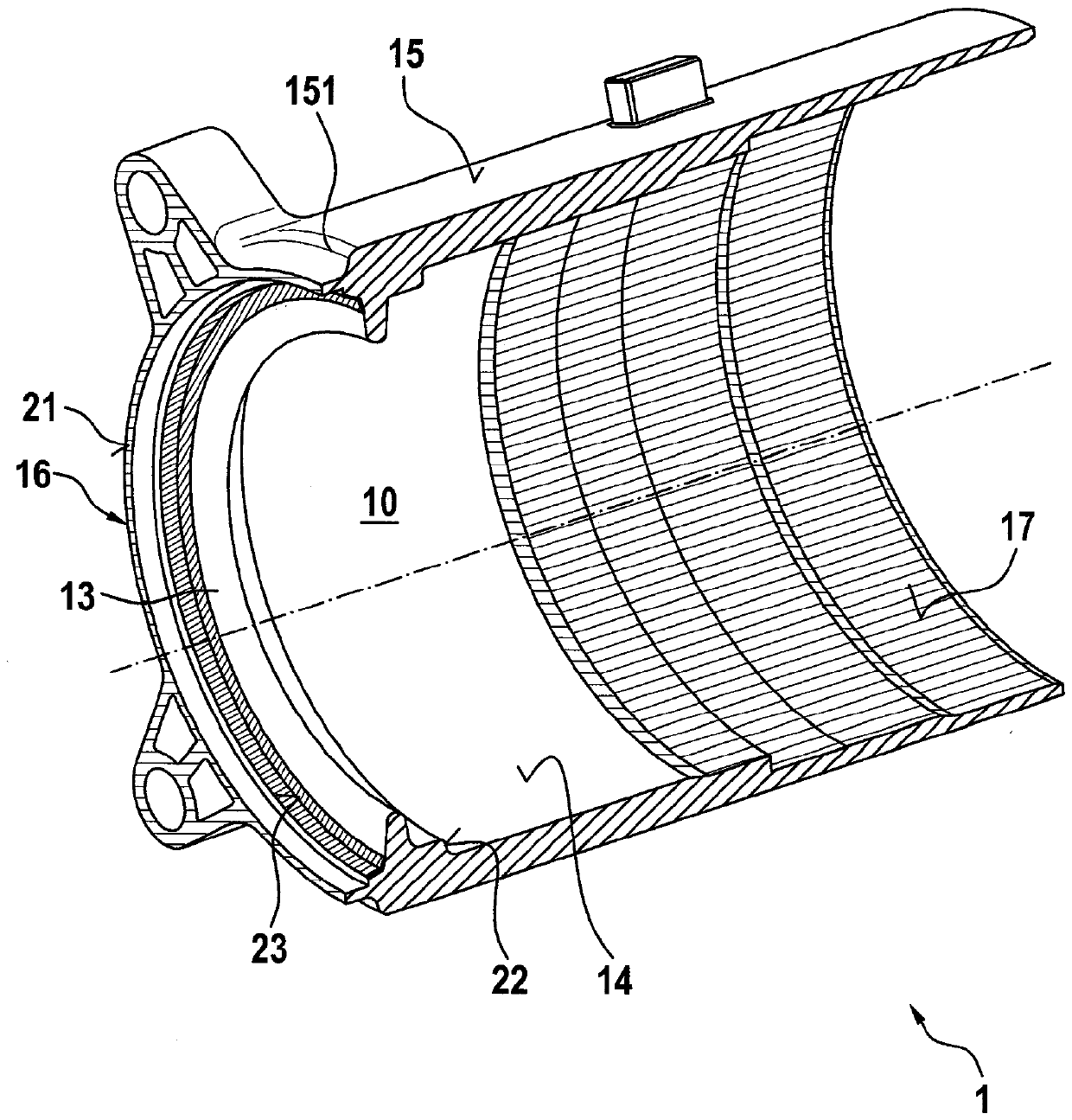

Housing of motor provided with pouring bearing and bearing cover

Owner:ROBERT BOSCH GMBH

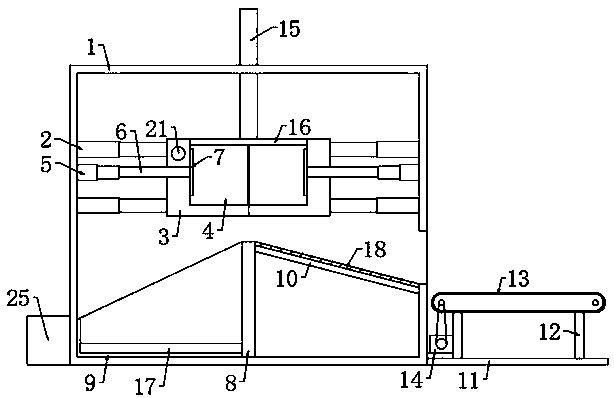

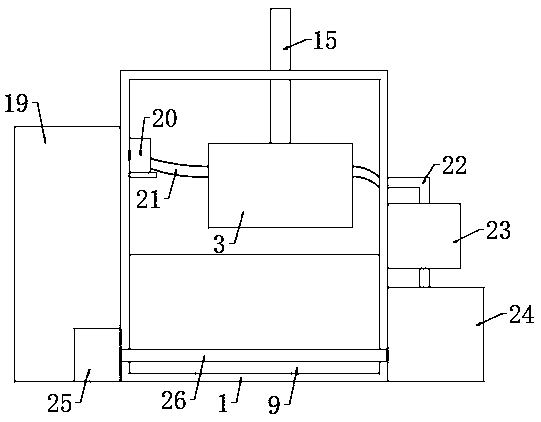

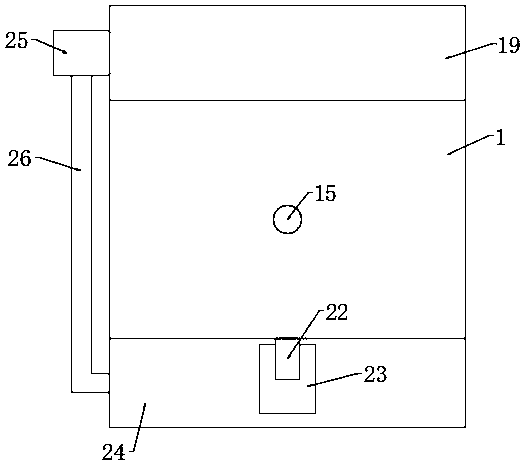

Drying and making equipment for woodchip pellets

InactiveCN112344673APreparation automationImprove drying effectDrying gas arrangementsWood working apparatusGear wheelWind power

The invention discloses drying and making equipment for woodchip pellets. The equipment comprises a drying box. A drying chamber with an upward opening is formed in the drying box, a fan chamber withthe left and the right symmetrical is formed in the lower wall of the drying chamber in a communication manner, a gear switching chamber is formed in the lower side of the fan chamber, the lower wallof the fan chamber is rotationally connected with a fan shaft extending downwards into the gear switching chamber, the lower wall of the gear switching chamber is connected with a sliding block in themanner of sliding leftwards and rightwards, the right wall of the gear switching chamber is provided with a sliding guiding chamber with a rightward opening in a communication manner, and the gear switching chamber is internally provided with a drying mechanism extending upwards into the fan chamber. A shaking chamber with the left and the right symmetrical is arranged on the upper end face of the drying box in a communication manner. According to the drying and making equipment for the woodchip pellets, switching is carried out through a gear moving leftwards and rightwards among fans to start different fans so as to blow wood chips from different directions, the wood chips can roll over, a better drying effect is achieved, and meanwhile, a top cover is blown upwards through wind power and falls down to generate shaking.

Owner:东阳潘辰竹木工艺品有限公司

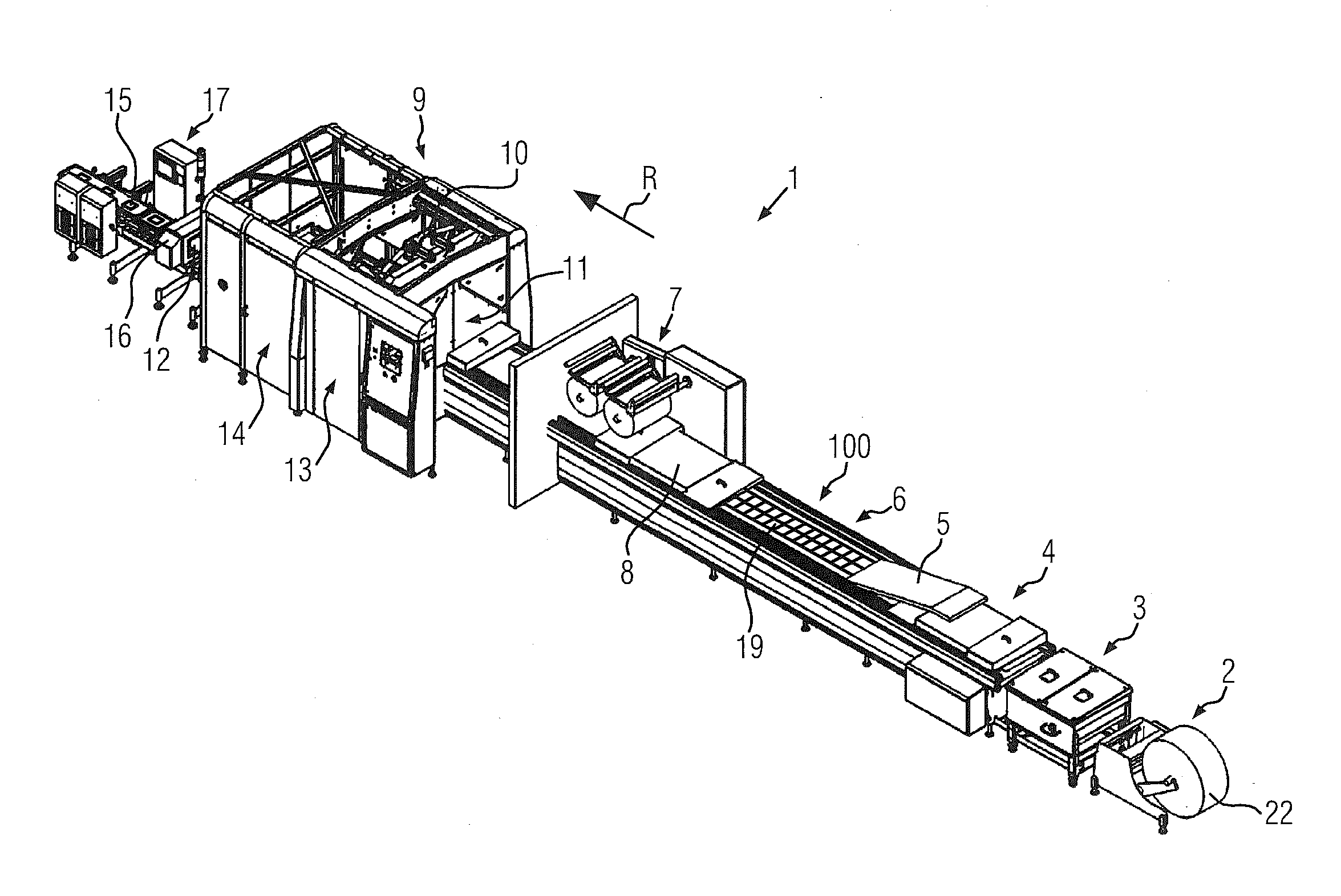

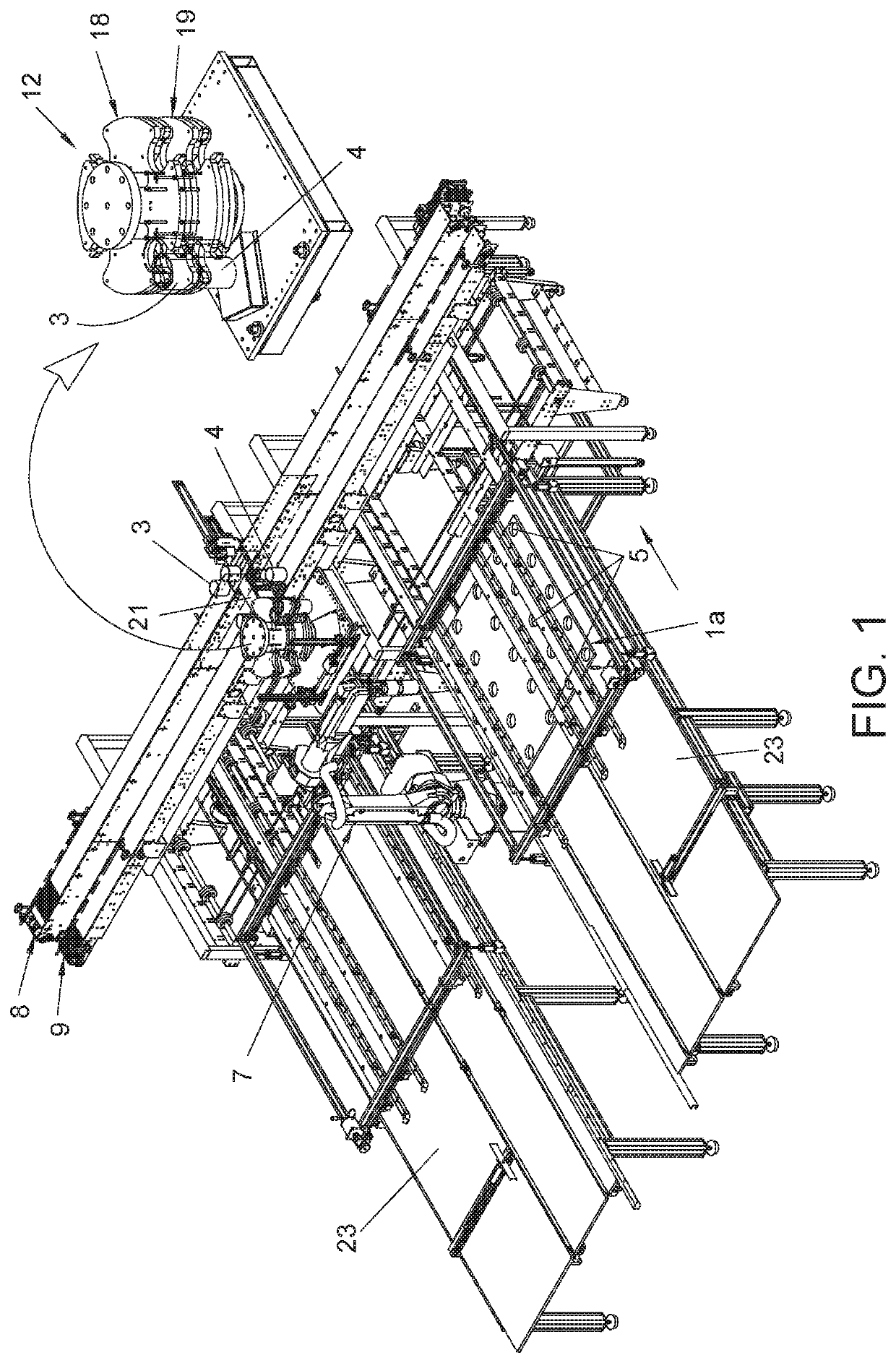

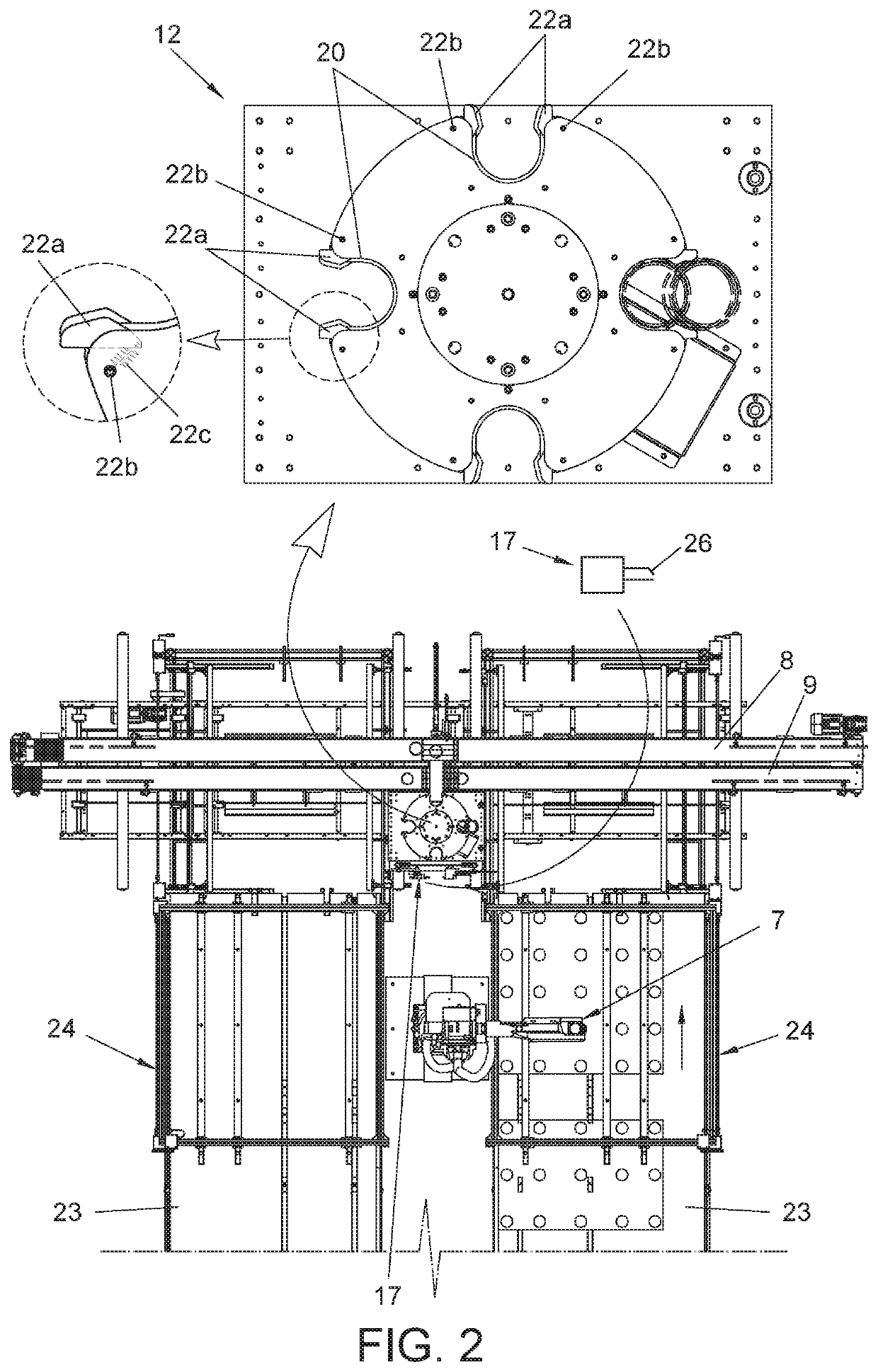

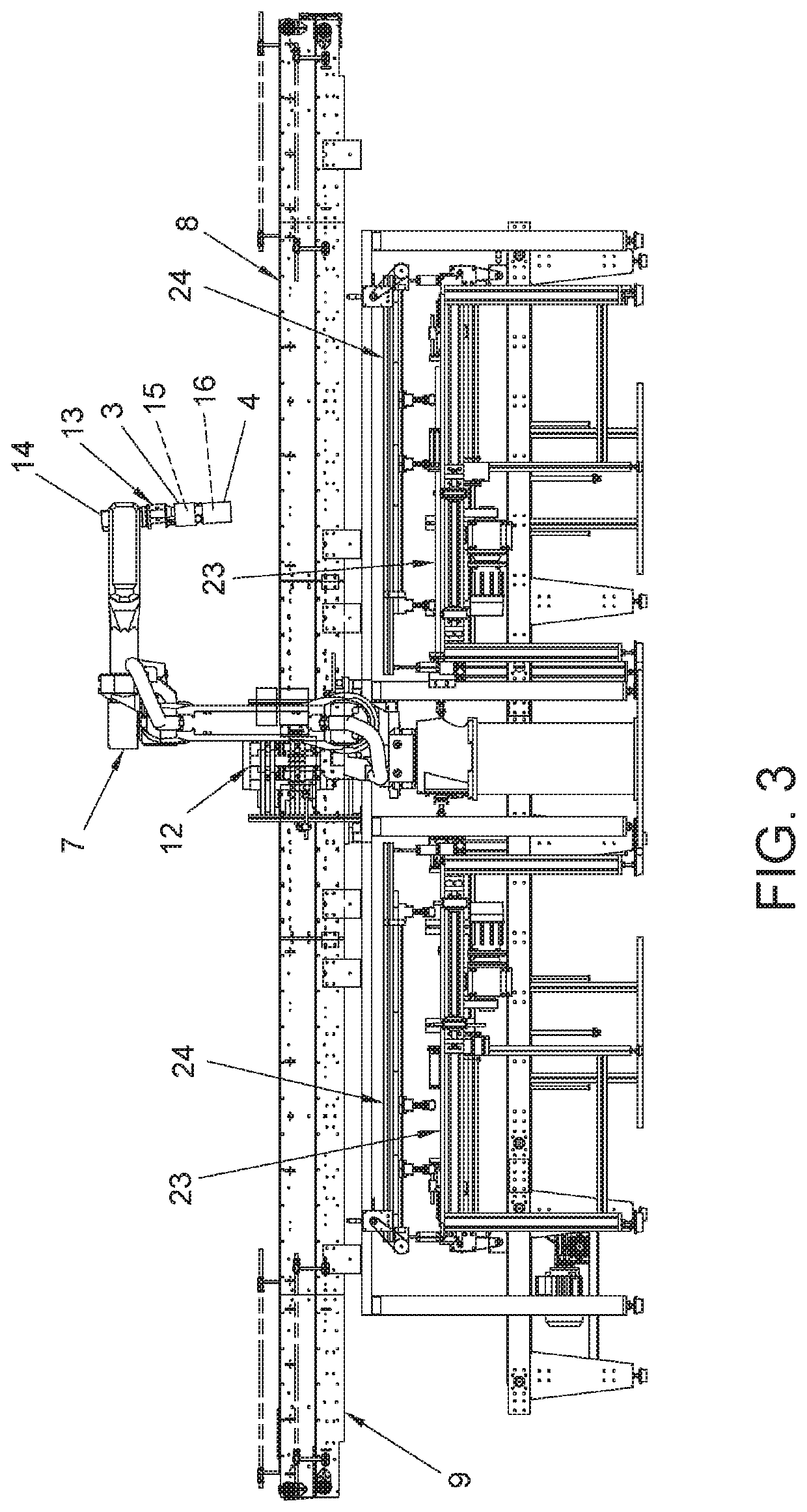

Machine for Manufacturing Pallets

ActiveUS20200180158A1ManufactureReducing final costPaper/cardboard articlesGripping headsRobotic armEngineering

The machine comprises a rotary feeder configured to receive the first tubular body and the second tubular body; wherein the first tubular body and the second tubular body are secured to one another separately in a single coaxial direction in the rotary feeder; and wherein the two tubular bodies make up separators of the pallets. The machine also comprises a robotic arm configured to transfer the two tubular bodies in pairs from the rotary feeder to an area above a transport table on which a first base of the pallet rests; so that one of the end portions of the second tubular body fits into an opening of the first base; wherein the robotic arm places the first tubular body around the second tubular body.

Owner:MANDRILADORA ALPESA SL

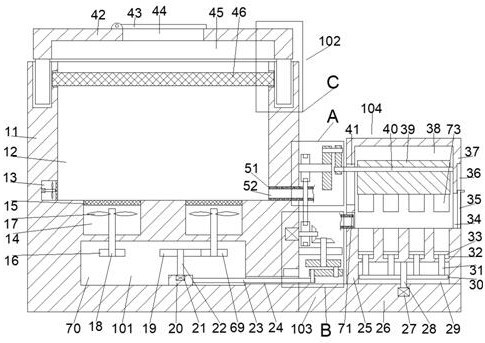

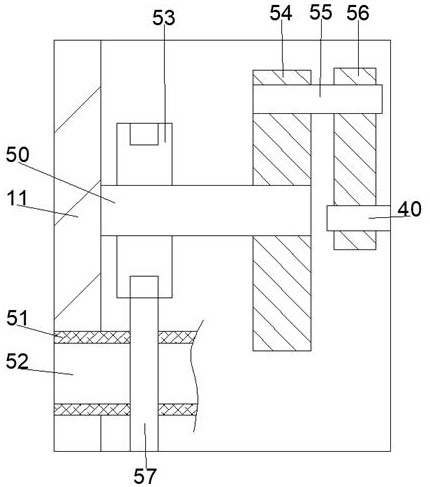

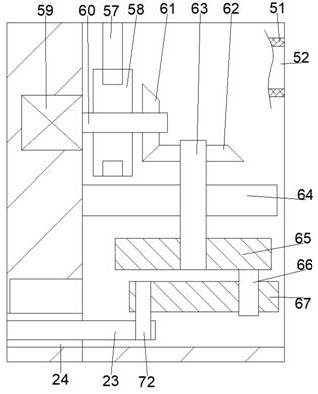

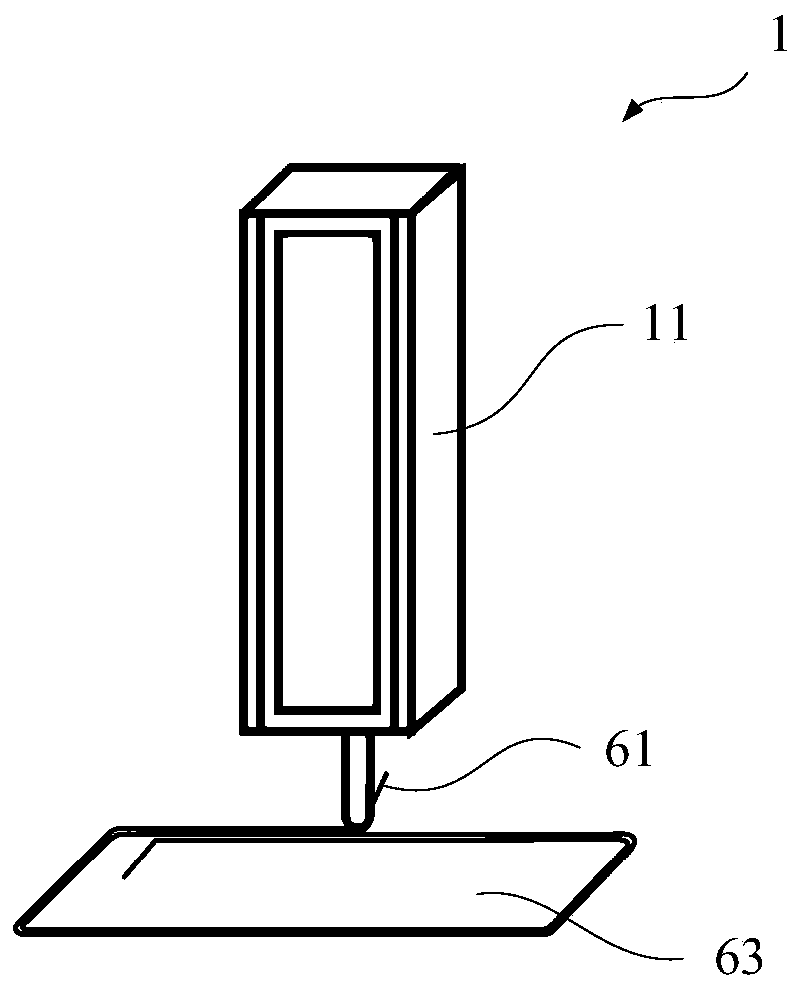

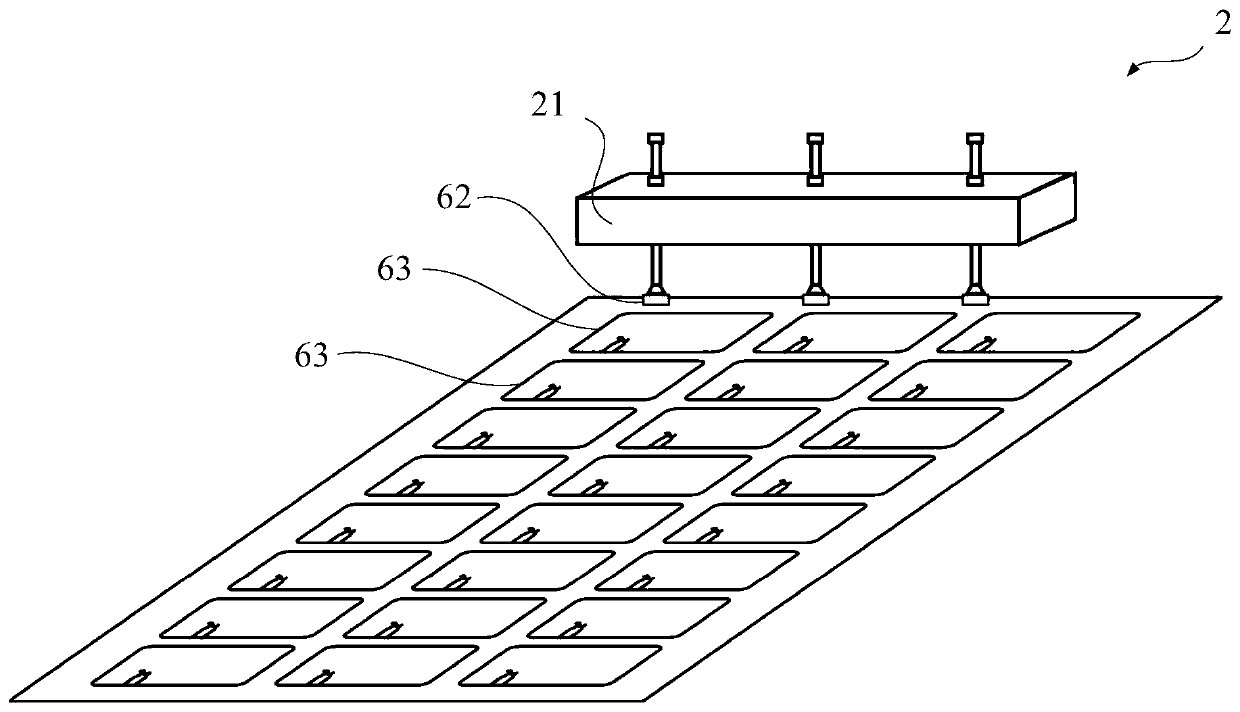

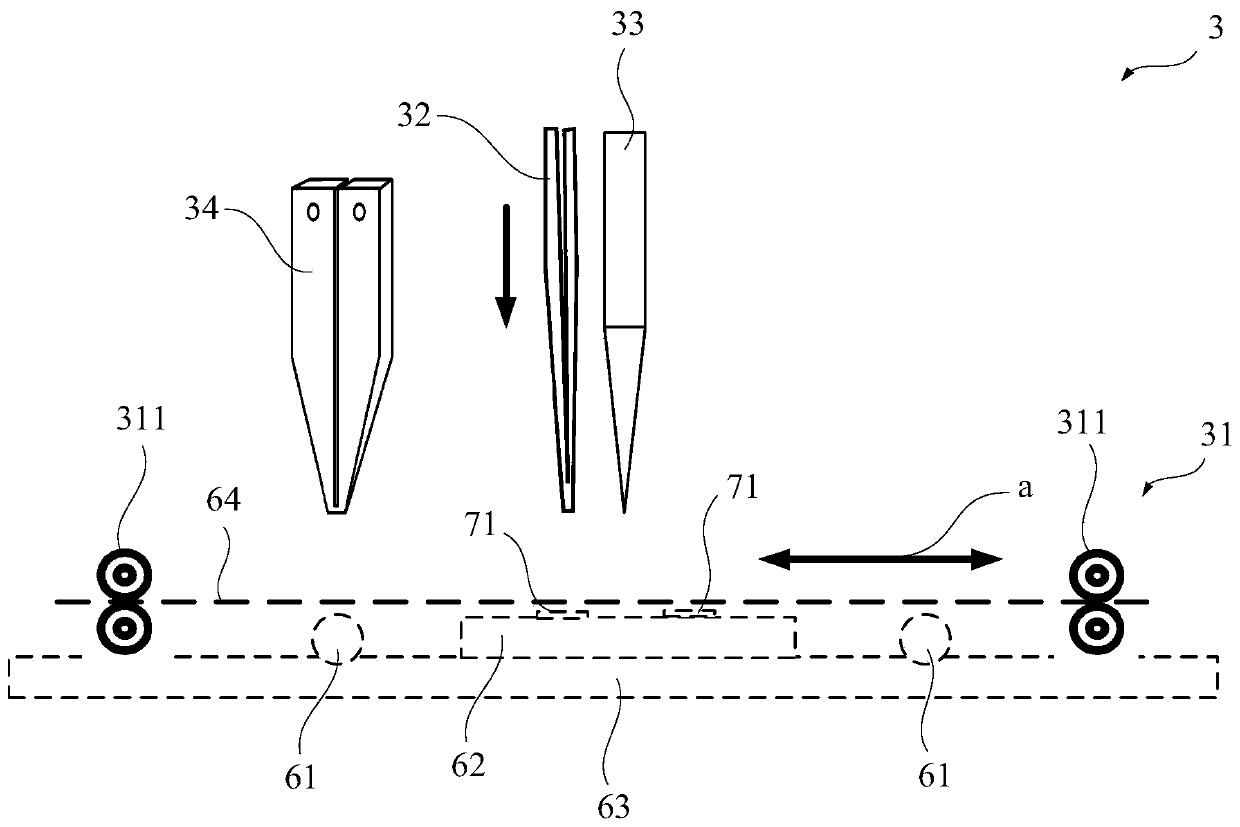

Non-contact card manufacturing device and non-contact card manufacturing method

ActiveCN109786305AAvoid damagePreparation automationAntenna supports/mountingsSemiconductor/solid-state device manufacturingCopper wireImplanted device

The invention discloses a non-contact card manufacturing device and a non-contact card manufacturing method. The non-contact card manufacturing device comprises an antenna implanting device used for implanting copper wires into a card manufacturing base material, a chip fixing device used for placing a chip in a fixed position of the card manufacturing base material, a pin welding device used forwelding the two ends of a lead wire to pins and copper wires of the chip, and a conveying device used for conveying the card manufacturing base material among the antenna implanting device, the chip fixing device and the pin welding device. According to the non-contact card manufacturing device and the non-contact card manufacturing method, the conveying device is used for conveying the card manufacturing base material, so that the card manufacturing base material can be conveyed among the devices corresponding to all processing links; and the required chip and antenna are arranged on the surface based on the card manufacturing base material, so that the manufacturing of a non-contact card is more automated and standardized, and the labor cost of the manufacturing is reduced.

Owner:SHANGHAI ORIENTAL MAGNETIC CARD ENG

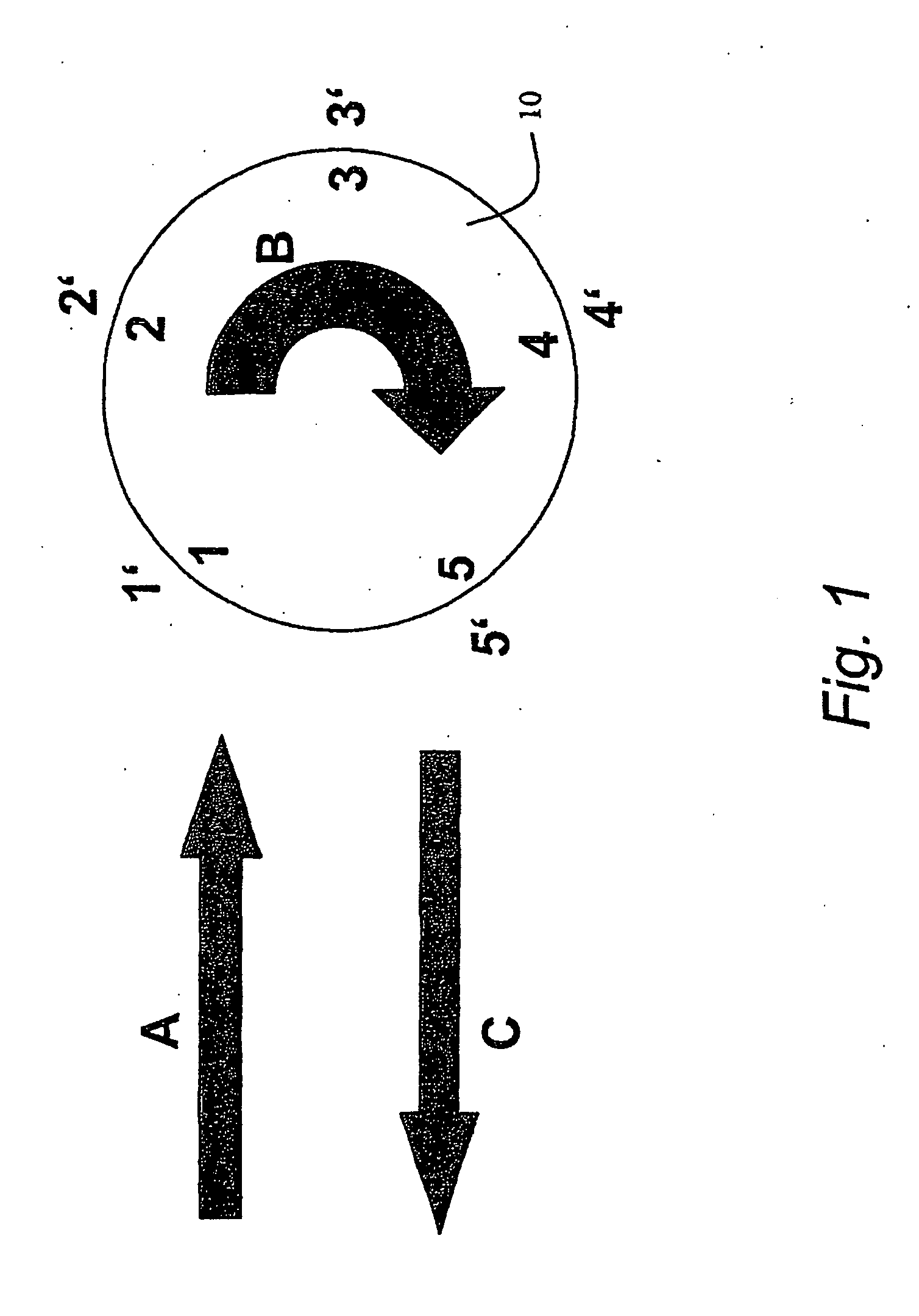

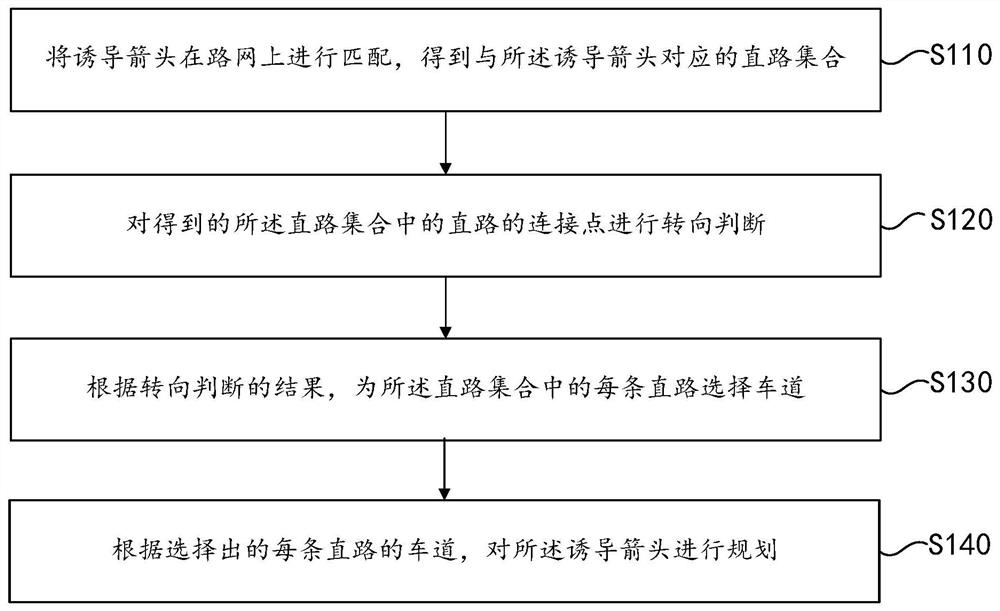

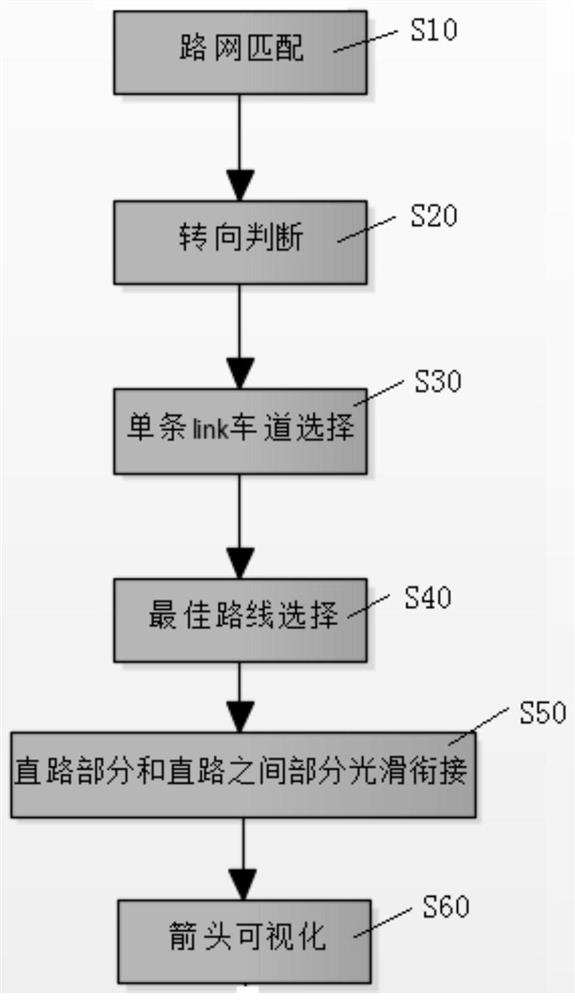

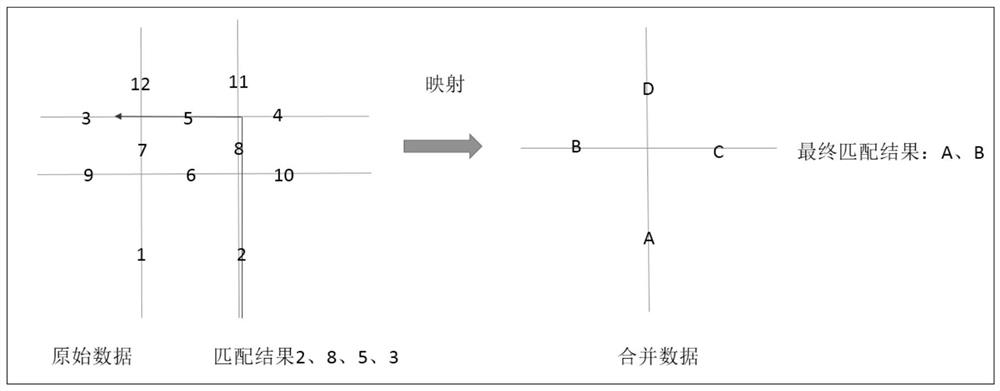

Induced arrow planning method, device, navigation system and storage medium

ActiveCN108801289BPreparation automationImprove navigation accuracyInstruments for road network navigationRoad networksNavigation system

Embodiments of the present invention provide a guiding arrow planning method, device, navigation system and storage medium. The method includes: matching the inducing arrows on the road network to obtain a set of straight roads corresponding to the inducing arrows; performing a steering judgment on the connection points of the straight roads in the obtained straight road set; according to the result of the steering judgment, for the A lane is selected for each straight road in the straight road set; and the guiding arrow is planned according to the selected lane of each straight road. The embodiment of the present invention uses the shape points given by the road calculation and the vehicle information on the straight road in the road network to calculate the shortest induced arrow plan for driving in the correct lane, automatic production, and high navigation accuracy.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Housings and bearing shields for electric motors with cast bearings

InactiveCN104734406BGood adhesionImprove rigiditySupports/enclosures/casingsElectric machineStructural engineering

The invention relates to a housing for an electric motor, comprising a housing blank extending concentrically around an axis and having an inner cavity, on which fastenings extending into the inner cavity are provided. A sheet, wherein an injection-molded part is molded on the fixed sheet, and the bearing is molded into the injection-molded part. The invention also relates to a bearing cover for an electric motor, which has a bearing molded into the injection molded part. The invention also relates to an electric motor with such a housing and / or such a bearing cover, as well as an adjustable drive with such an electric motor.

Owner:ROBERT BOSCH GMBH

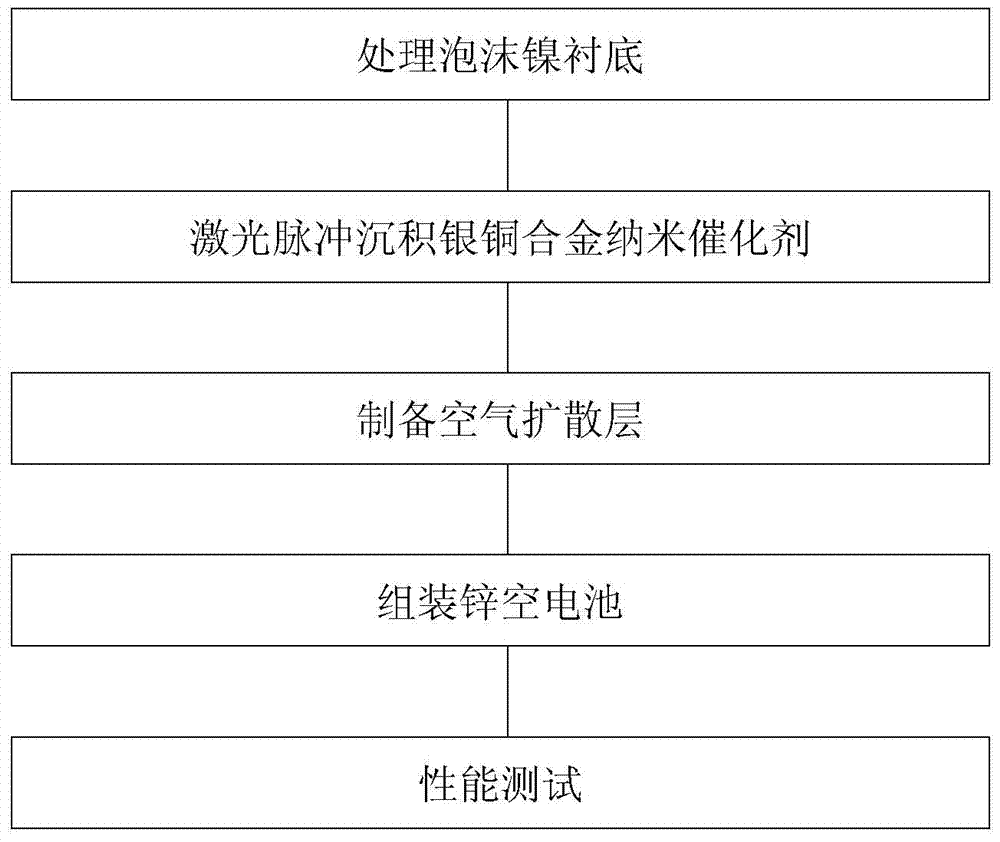

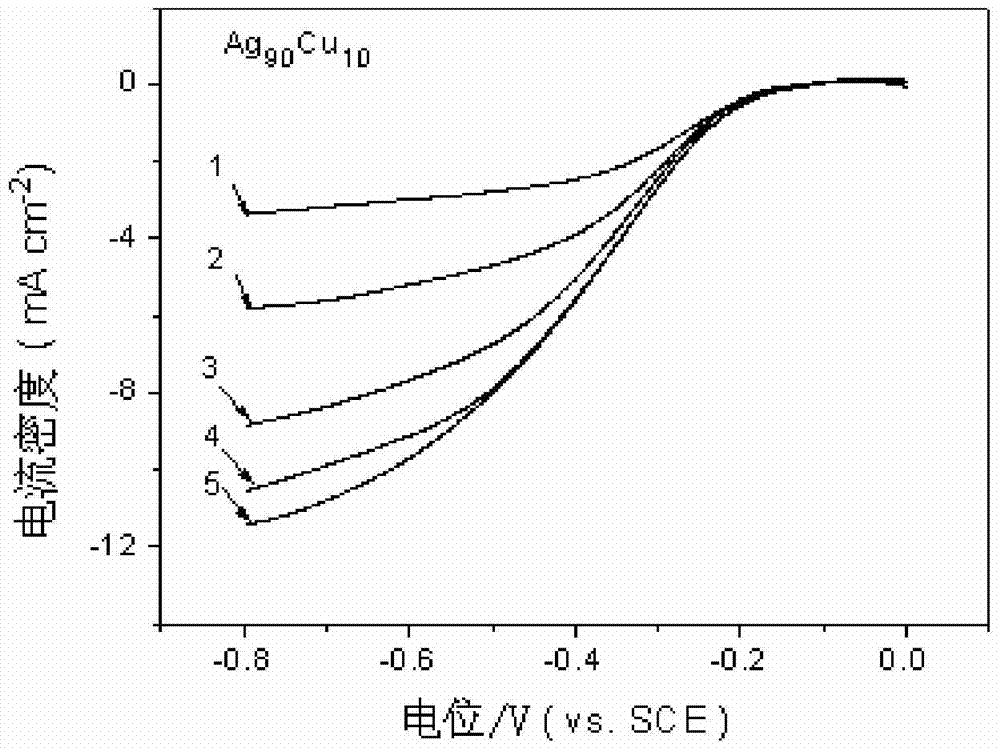

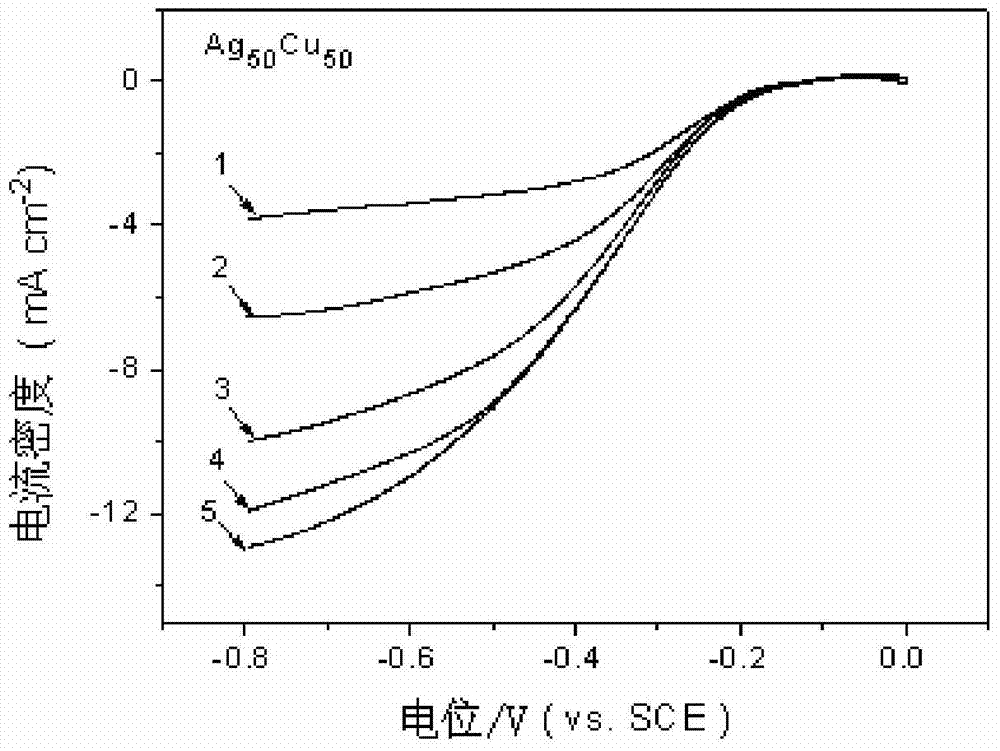

Silver-copper nano-alloy air electrode catalyst layer and deposition method thereof

The invention relates to a silver copper nano alloy air electrode catalyst and a deposition method thereof. The silver copper nano alloy air electrode catalyst layer is in a film shape and consists of 50 to 90 percent of Ag and 10 to 50 percent of Cu, wherein the percentage is the atomic percentage. The silver copper nano alloy is directly deposited onto a foam nickel current collector electrode by adopting a pulse laser deposition method, a silver copper single-phase solid solution alloying cathode catalyst layer is prepared to form a catalytic layer which does not contain carbon and contains Teflon. The micro tissue of the silver copper nano alloy air electrode catalyst layer is formed by dispersing silver copper nano alloy particles in a copper amorphous substrate, the average nano particle granularity is 2.5nm to 2.8nm, and the distribution granularity is 1nm to 5nm. The open-circuit voltage of the silver copper nano alloy film in a primary zinc-air battery is 1.42V to 1.44V, the power density can reach up to 86.3mW.cm<-2> and is improved by 20 percent, and the charging-discharging circulating efficiency in a secondary zinc-air battery is more than 41 percent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

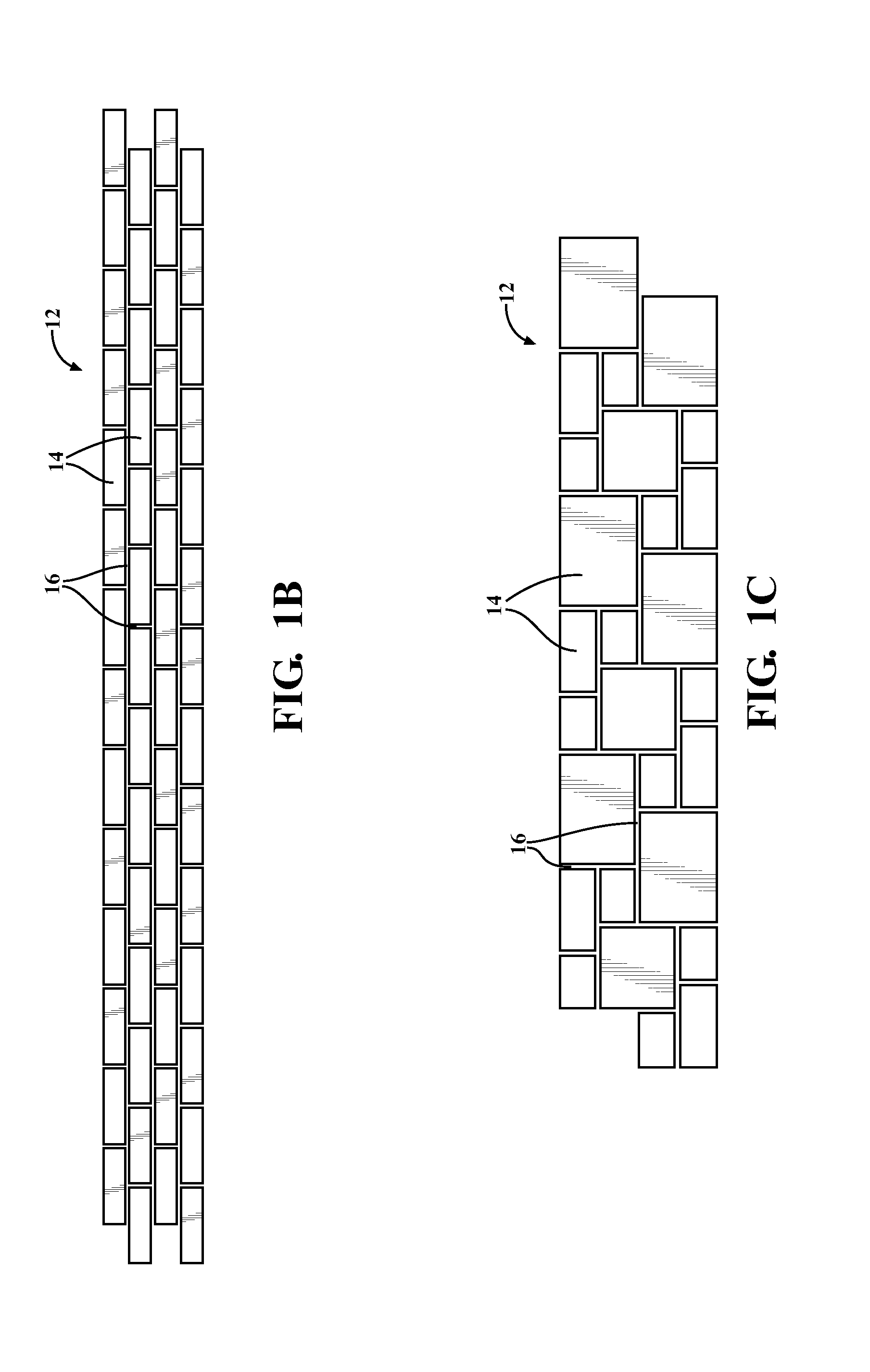

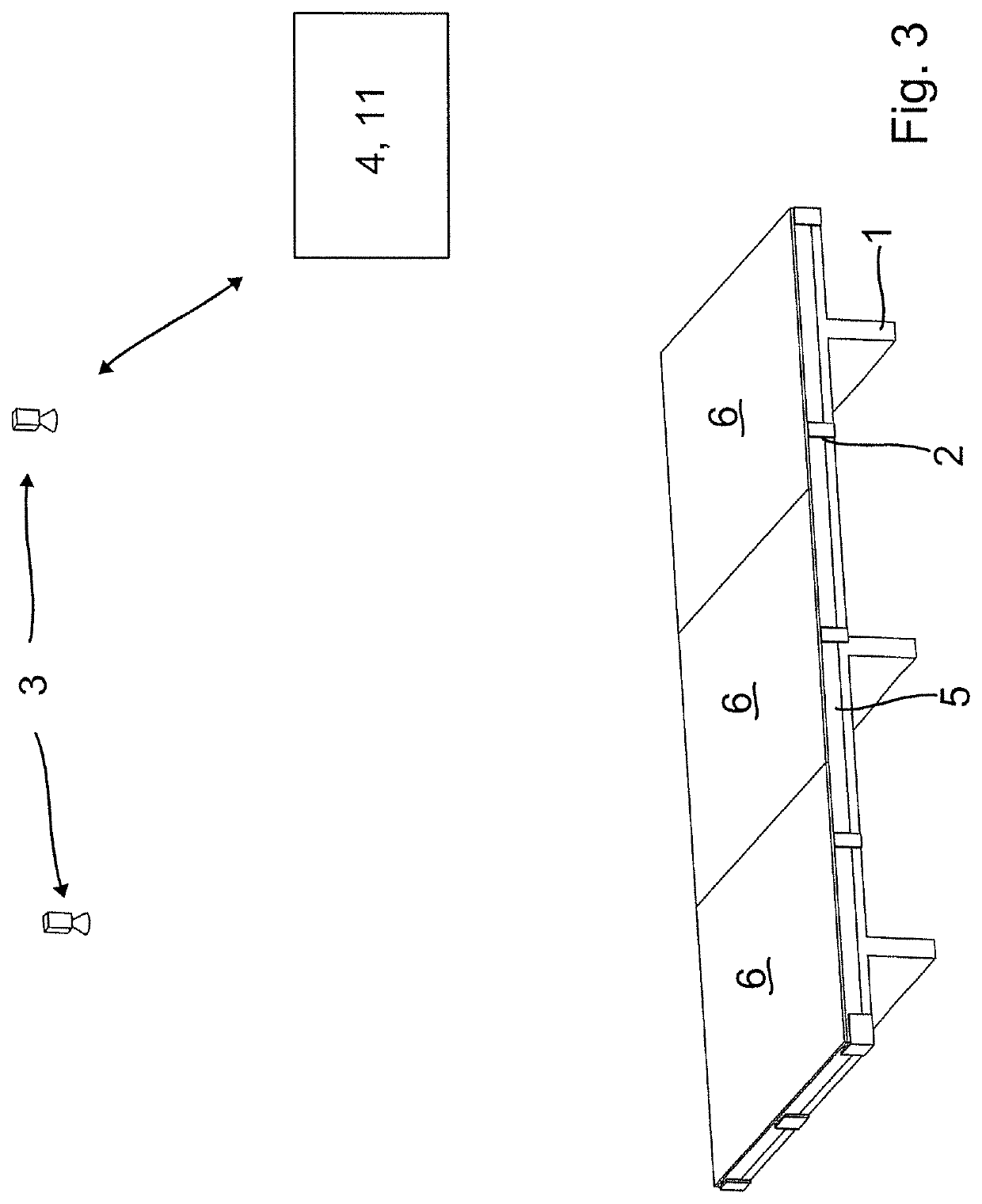

Process for manufacturing wall elements from nailable and/or stapleable materials

ActiveUS10919176B2Preparation automationLittle effortStapling toolsConstruction materialWall plateRobot locomotion

A process for manufacturing wall elements from nailable and / or stapleable materials, in which a wall element frame is positioned on a horizontal worktable. Wall panels are placed on the frame and the wall panels are fastened to the frame by nails and / or staples, which are driven by a compressed air setting device. A mobile robot—in particular an autonomous mobile robot—has a compressed air setting device and / or at least one milling unit and is movable on the surface formed by the wall panels. The robot motion is automatically controlled along the surface formed by the wall panels. At predetermined positions, the milling unit and / or the compressed air setting device is actuated to process the wall panels and / or to fasten them to the wall element frame.

Owner:RAIMUND BECK NAGELTECHNIK GMBH

Casting tank for producing metal products

InactiveCN111215609APreparation automationAvoid wastingMolten metal conveying equipmentsHydraulic cylinderEngineering

The invention discloses a casting tank for producing metal products. The casting tank comprises a shell, wherein a plurality of first hydraulic cylinders are fixedly arranged at the two sides inside the shell, a casting mold is fixedly arranged between telescopic rod ends of the first hydraulic cylinders, a cavity is formed inside the casting mold, second hydraulic cylinders are fixedly arranged at the portion, between the first hydraulic cylinders, at the two sides inside the shell, push rods are arranged between telescopic rod ends of the second hydraulic cylinders, a squeezing plate is fixedly arranged at the end, away from the corresponding second hydraulic cylinder, of each push rod inside the cavity, a clapboard is fixedly arranged at the lower end inside the shell, and a storage boxis arranged at the portion, located at one side of the clapboard, inside the shell. Through the arrangement of the casting tank for producing the metal products, when the metal products are produced,automatic demolding can be carried out, classified treatment can be conducted according to the production quality of finished products, and therefore, the casting tank has the advantages of being high in production efficiency and capable of saving production resources.

Owner:江苏旋压机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com