Housing of motor provided with pouring bearing and bearing cover

A bearing cap and housing technology, applied in the field of adjustable driving devices, can solve the problems of infeasibility and achieve the effects of shortening the tolerance chain, low cost, and reduced operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

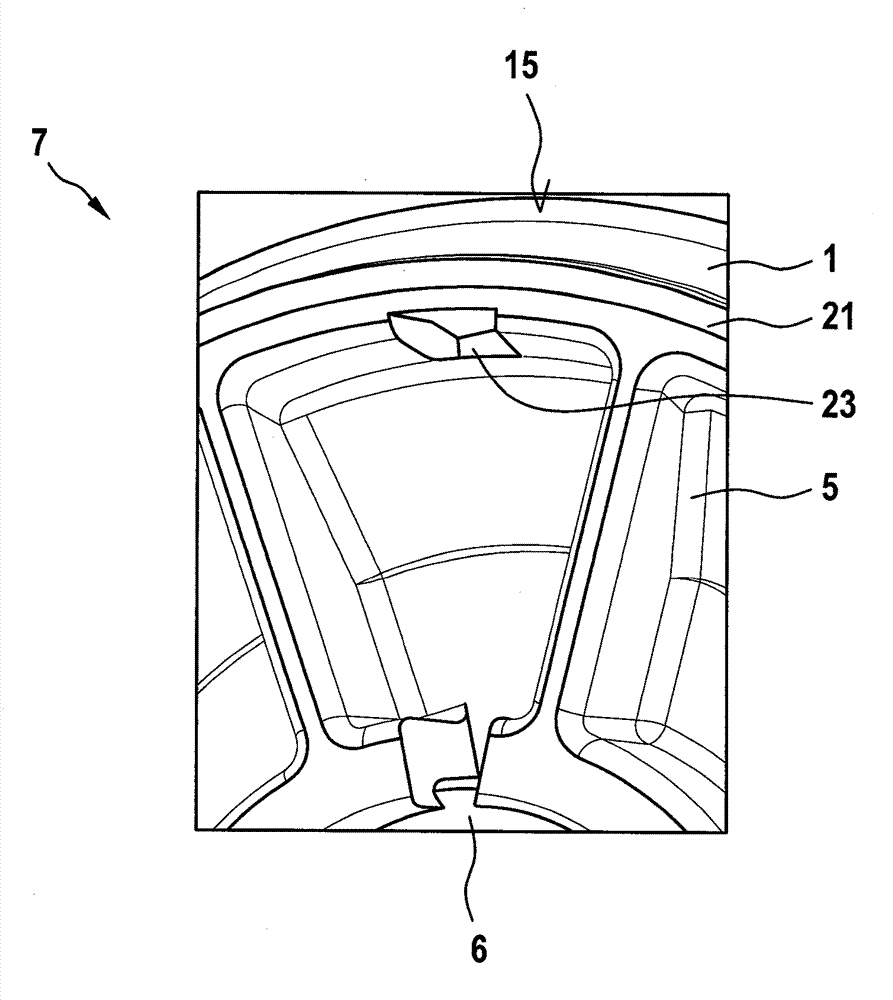

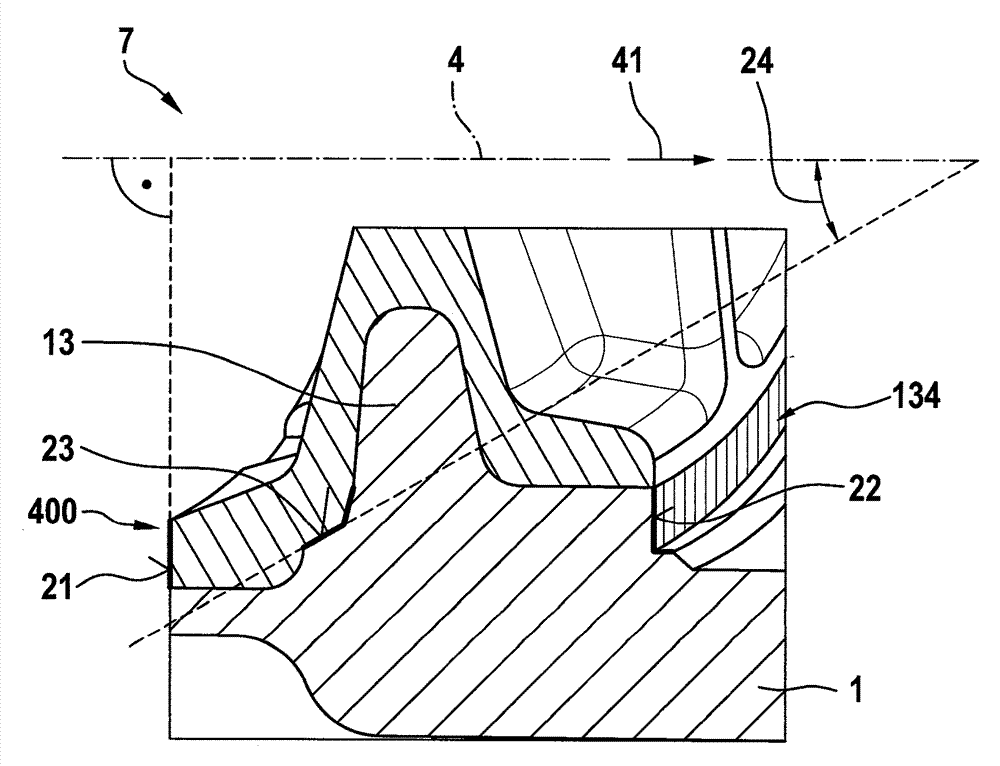

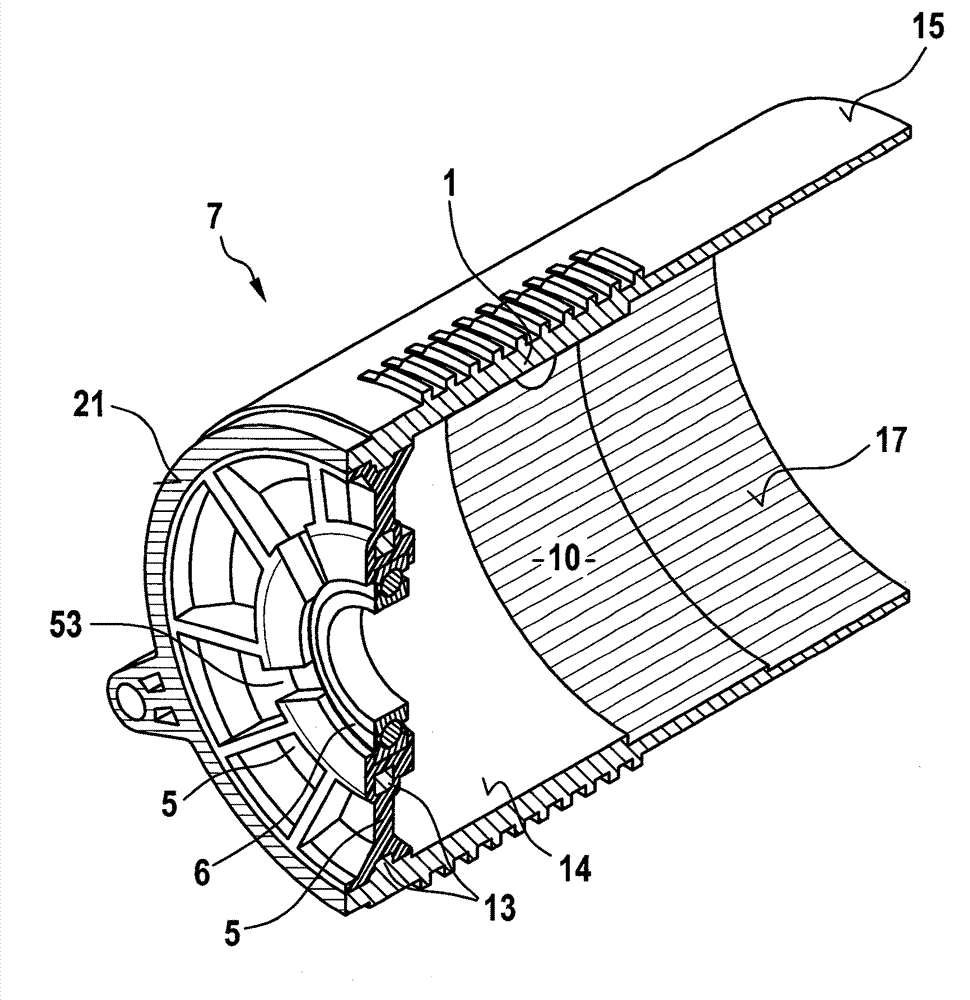

[0053] FIG. 1 shows a housing blank 1 for a housing 7 (see FIG. 2 ) of an electric machine 100 . The housing blank 1 is made approximately cylindrical. And it has an inner cavity 10 made approximately cylindrical. The fixing piece 13 extends into the inner cavity 10 . The housing blank 1 , the interior space 10 and the fastening plate 13 are arranged concentrically around the axis 4 . The housing blank 1 extends in an axial direction 41 .

[0054] Fastening tabs 13 are provided for arranging the injection molded part 5 formed from the curable compound 5 (see FIG. 2 ). The injection molded part 5 is provided for forming the bearing 6 (see FIG. 2 ) for the shaft 40 (see FIG. 8( b )) of the motor 100 (see FIG. 8( b )). The shaft 40 extends in an axial direction 41 . The hardened curable compound 5 forms the injection molded part 5 . Therefore, the terms curable mass and injection molded part are used synonymously below.

[0055] A tool (not shown) is required in order to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com