Drying and making equipment for woodchip pellets

A technology for manufacturing equipment and granules, which is applied in the direction of wood granule drying, drying, dryers, etc., can solve the problems of mildew, poor effect, uneven drying method, etc., achieve good drying effect and prevent clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

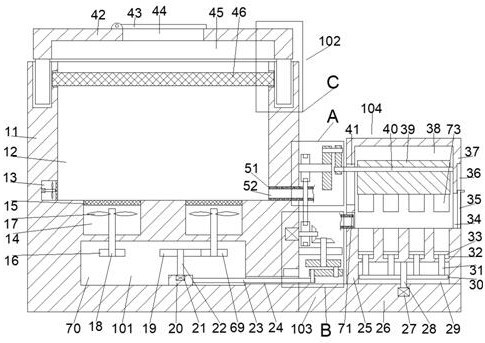

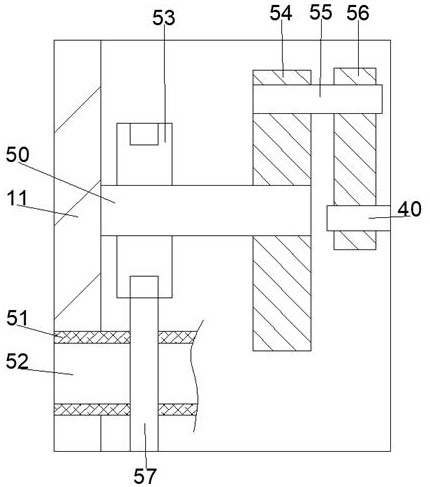

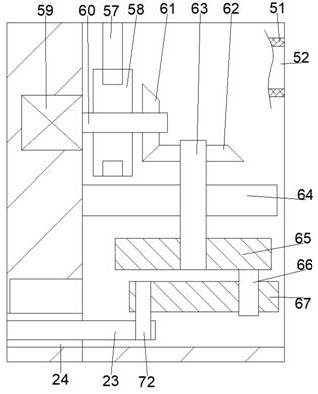

[0015] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] The drying and manufacturing equipment of wood pellets according to the present invention includes a drying box 11, the drying box 11 is provided with a drying chamber 12 with an upward opening, and the lower wall of the drying chamber 12 is connected with a Left and right symmetrical fan chamber 14, the lower side of the fan chamber 14 is provided with a gear switching chamber 70, the lower wall of the fan chamber 14 is rotatably connected with a fan shaft 18 extending downward into the gear switching chamber 70, the gear The lower wall of the switching chamber 70 slides left and right and is connected with a sliding block 20. The right wall of the gear switching chamber 70 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com