Silver-copper nano-alloy air electrode catalyst layer and deposition method thereof

A nano-alloy, air electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the shedding of Ag-based catalytic active components, weak catalytic activity of oxygen reduction reaction, and reduced catalytic activity of air electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

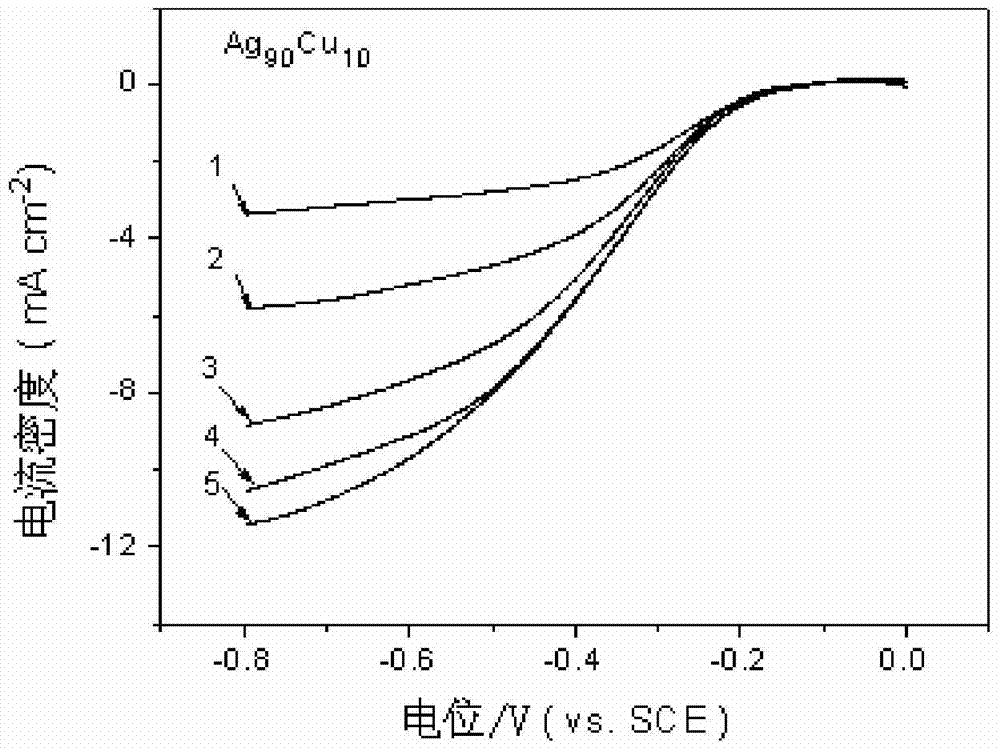

[0029] This embodiment is a silver-copper nano-alloy air electrode catalyst layer.

[0030] The silver-copper nano-alloy air electrode catalyst layer is a thin film composed of 50-90% Ag and 10-50% Cu, and the stated percentages are atomic percentages. In this embodiment, the atomic percentage of Ag is 90%, and the atomic percentage of Cu is 10%. Through transmission electron microscope observation, the microstructure of the silver-copper nano-alloy air electrode catalyst layer is silver-copper nano-alloy particles dispersed in the copper amorphous matrix, the average particle size of the nanoparticles is 2.8nm, and the distribution particle size is between 1 and 5nm. between.

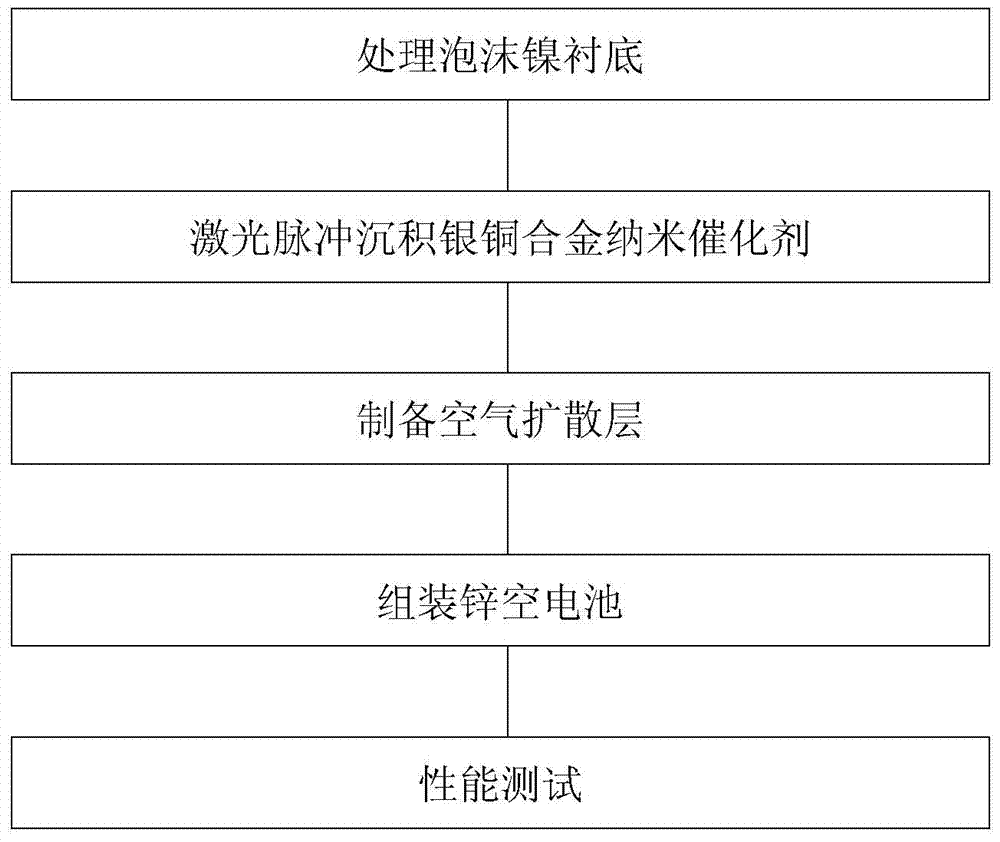

[0031] This embodiment also proposes a method for preparing the silver-copper nano-alloy air electrode catalyst layer, the specific process is:

[0032] Step 1, processing the nickel foam substrate. Take nickel foam with a thickness of 1 mm and soak it in acetone for 3 hours to remove oil, soak it i...

Embodiment 2

[0040] This embodiment is a silver-copper nano-alloy air electrode catalyst layer.

[0041] The silver-copper nano-alloy air electrode catalyst layer is a thin film composed of 50-90% Ag and 10-50% Cu, and the stated percentages are atomic percentages. In this embodiment, the atomic percentage of Ag is 75% and the atomic percentage of Cu is 25%. Through transmission electron microscope observation, the microstructure of the silver-copper nano-alloy air electrode catalyst layer is silver-copper nano-alloy particles dispersed in the copper amorphous matrix, the average particle size of nanoparticles is 2.5nm, and the distribution particle size is between 1 and 5nm. between.

[0042] This embodiment also proposes a method for preparing the silver-copper nano-alloy air electrode catalyst layer, the specific process is:

[0043] Step 1, processing the nickel foam substrate. Take nickel foam with a thickness of 1 mm and soak it in acetone for 3 hours to remove oil, soak it in 5% ...

Embodiment 3

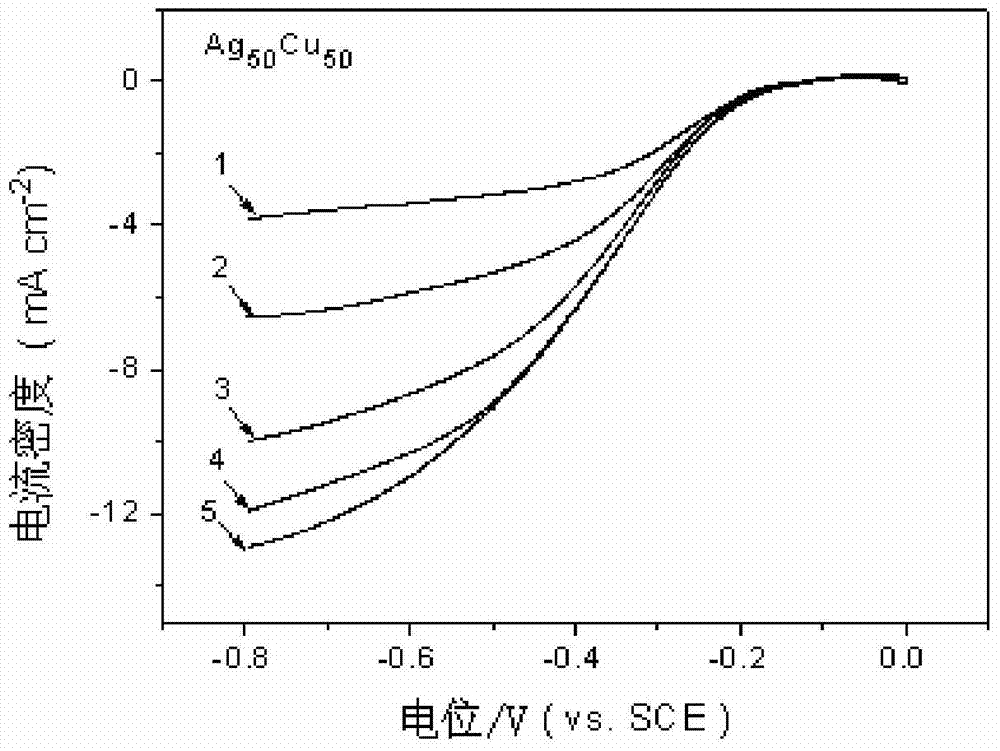

[0051] This embodiment is a silver-copper nano-alloy air electrode catalyst layer.

[0052] The silver-copper nano-alloy air electrode catalyst layer is a thin film composed of 50-90% Ag and 10-50% Cu, and the stated percentages are atomic percentages. In this embodiment, the atomic percentage of Ag is 50%, and the atomic percentage of Cu is 50%. Through transmission electron microscope observation, the microstructure of the silver-copper nano-alloy air electrode catalyst layer is silver-copper nano-alloy particles dispersed in the copper amorphous matrix, the average particle size of the nanoparticles is 2.6nm, and the distribution particle size is between 1 and 5nm. between.

[0053] This embodiment also proposes a method for preparing the silver-copper nano-alloy air electrode catalyst layer, the specific process is:

[0054] Step 1, processing the nickel foam substrate. Take nickel foam with a thickness of 1 mm and soak it in acetone for 3 hours to remove oil, soak it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com