Nesting control method and system

A technology for controlling units and plates, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of low reusability of residual materials, high labor dependence, long operation time, etc., to reduce the requirements, The effect of solving high dependency and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

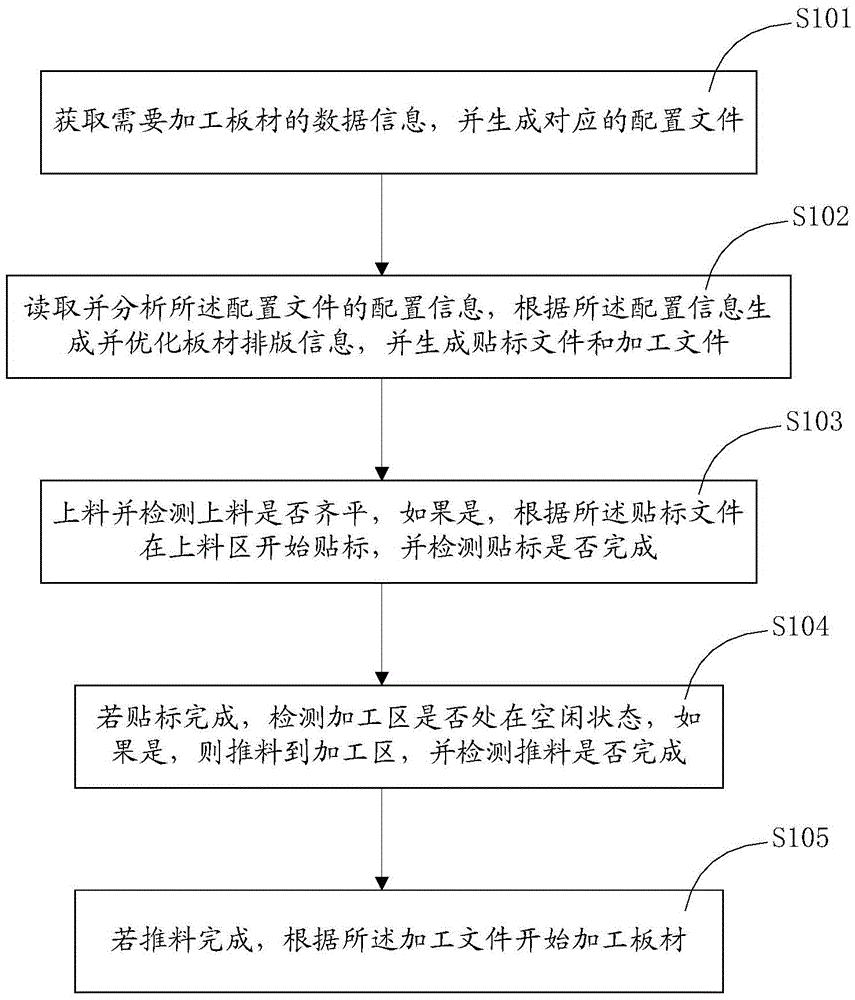

[0034] figure 1 It shows the flow of the method for controlling large-slab nesting provided by an embodiment of the invention, and the detailed process is as follows:

[0035] S101. Obtain the data information of the plate to be processed, and generate a corresponding configuration file.

[0036] In this step, the data information of the board to be processed is obtained, including the size of the furniture board, that is, length, width, thickness, etc.; the material of the board, such as hardness, etc.; also includes labeling information before processing; and specific processing information, such as punching, Milling, slotting and material cutting data, etc., generate corresponding configuration files according to the fixed format of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com