Connecting assembly for fastening an add-on element on a carrier element

a technology of connecting assembly and carrier element, which is applied in the direction of fastening means, press-button fasteners, vehicle components, etc., can solve the problems of limiting the general usability of the connecting assembly, one of the components, and the connecting technique does not permit the reuse of the connecting assembly under satisfactory circumstances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Though the invention is preferably applicable in the field of the lining of structures, and in particular in the field of motor vehicles and the lining of the car body with an inner lining, the invention is described below generally on the basis of a reversible fastening of an add-on element on a carrier element, in which the add-on element can be an inner lining part and the carrier element can be a car body part of a motor vehicle.

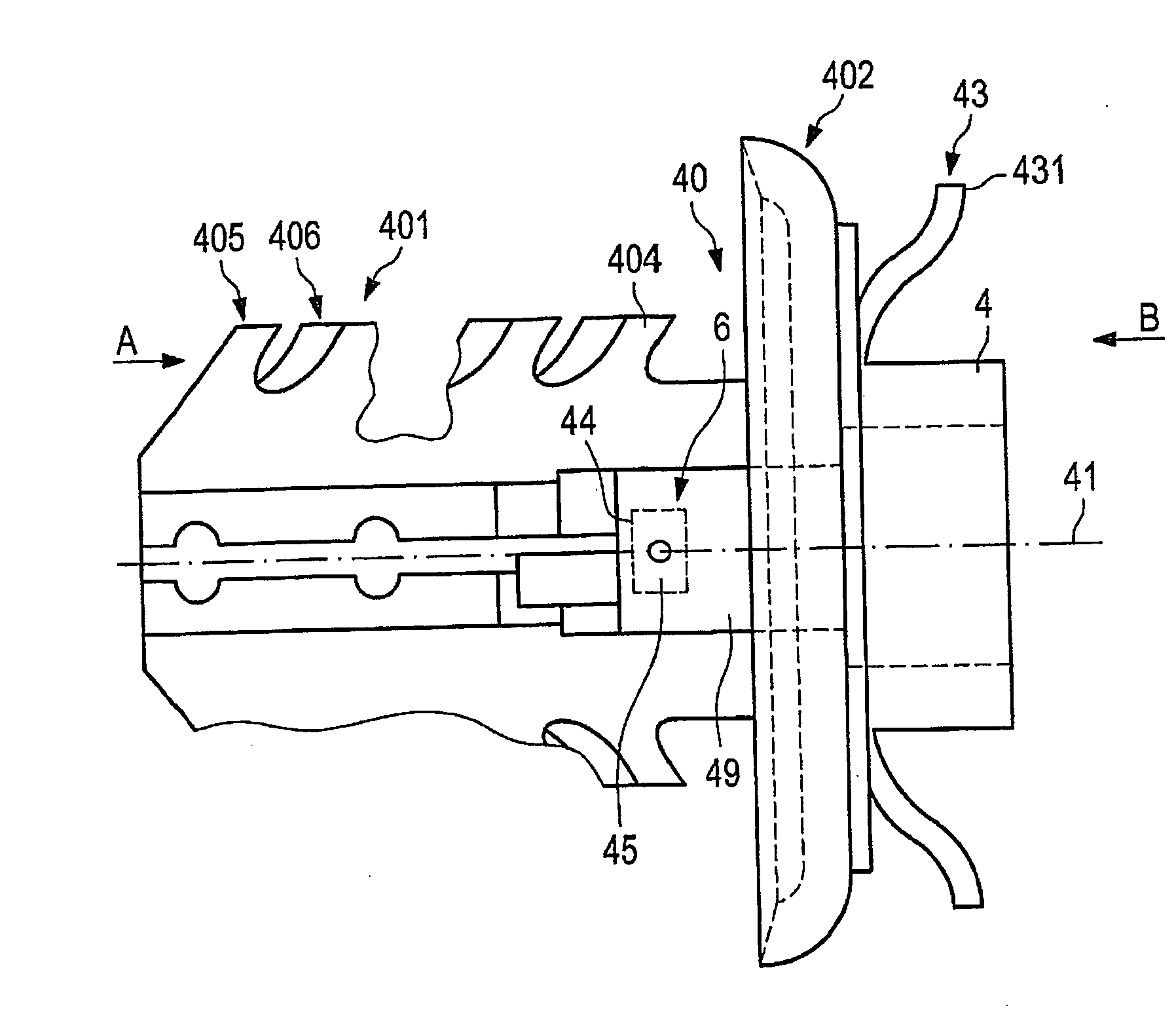

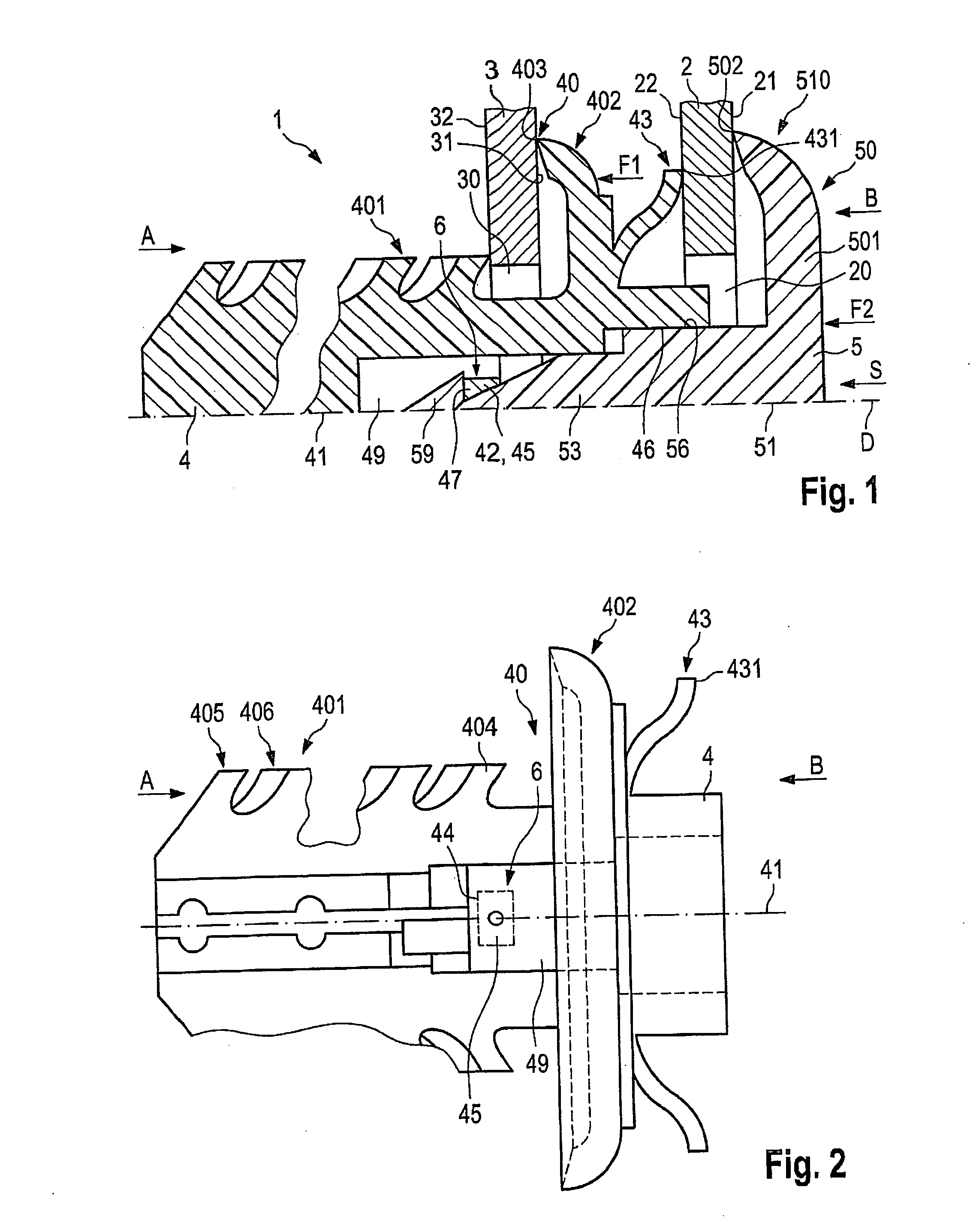

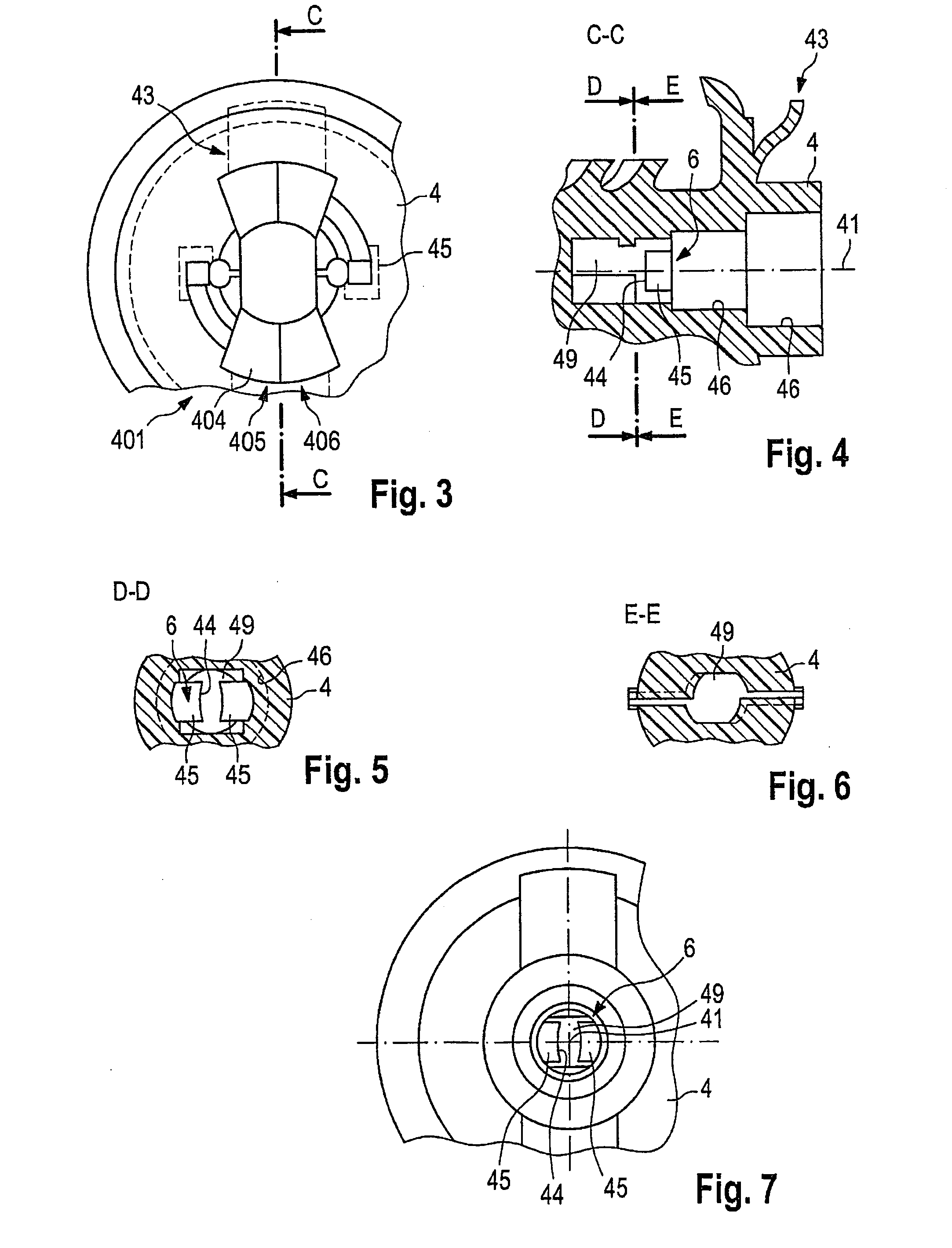

[0030]The connecting assembly 1 according to the invention which is illustrated in the figures serves to fasten an add-on element 2 on a front side 31 of a carrier element 3 and cooperates with the rim of an opening 30 formed in the carrier element 3.

[0031]The connecting assembly 1 includes as essential elements a foot 4 and a pin 5. In the embodiments shown in the figures, they form the two single components of the connecting assembly 1. The foot 4 and the pin 5 are made of plastic and in particular fabricated by injection molding. The foot 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com