Non-contact card manufacturing device and non-contact card manufacturing method

A contactless card and manufacturing equipment technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor costs, low quality of contactless cards, and low level of automatic manufacturing of contactless cards, and avoid Effects on the Chip Surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

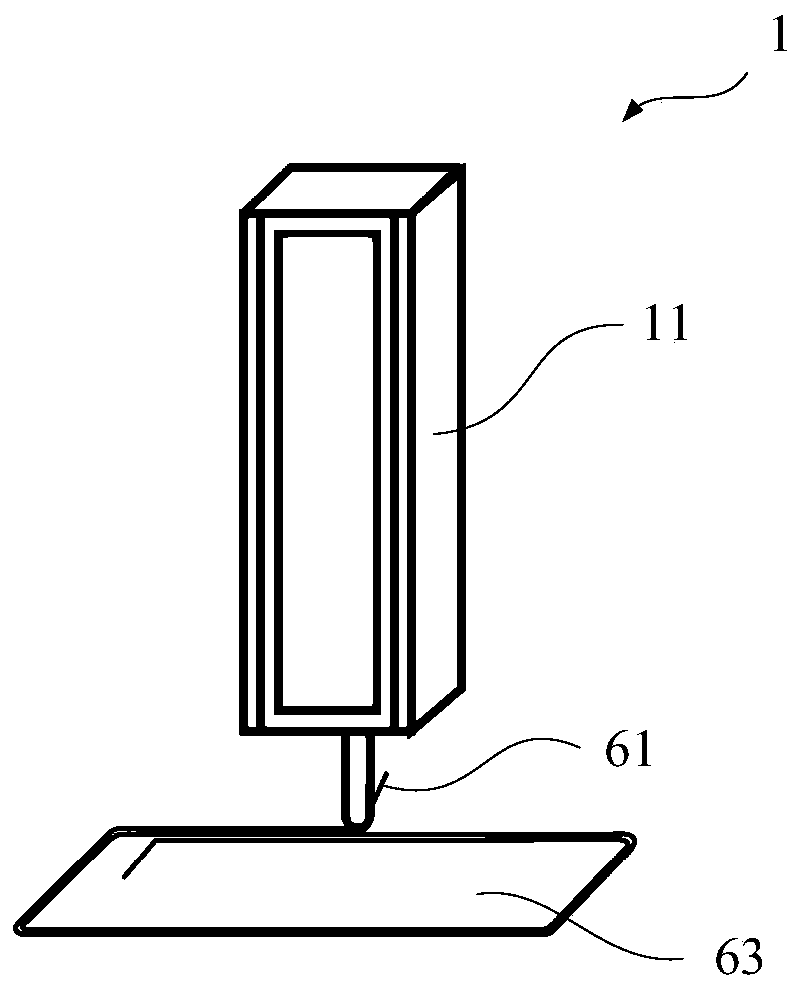

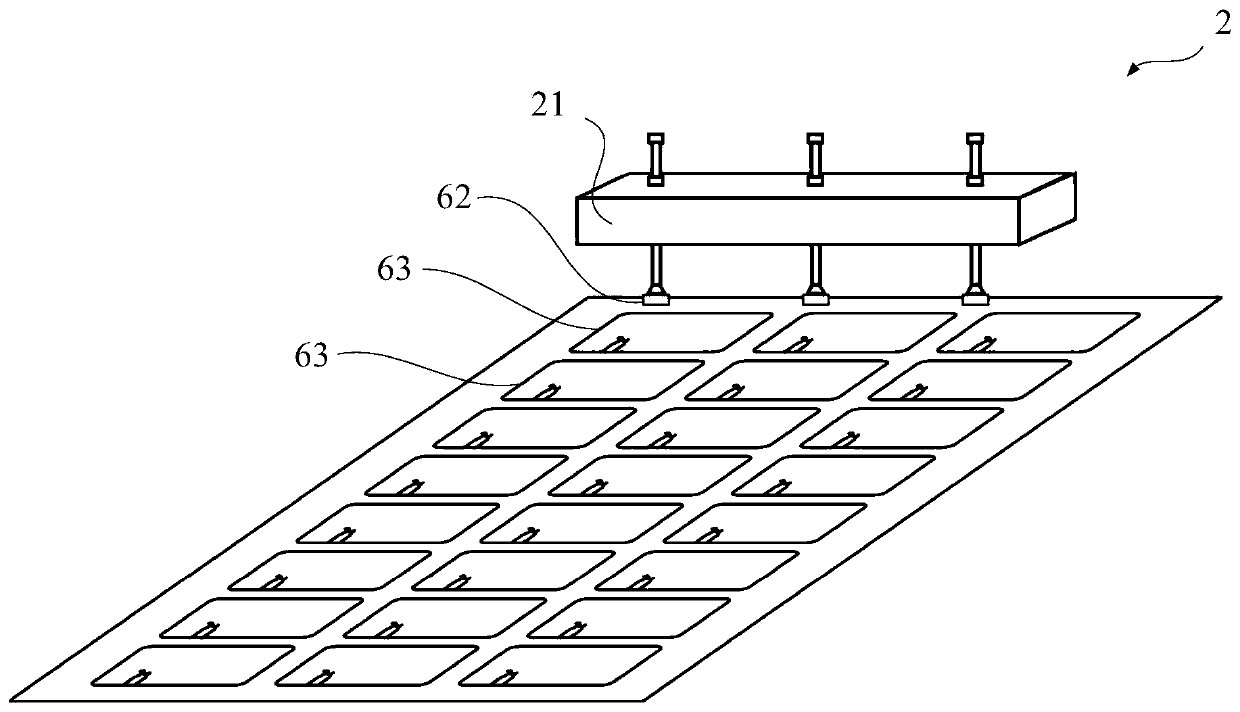

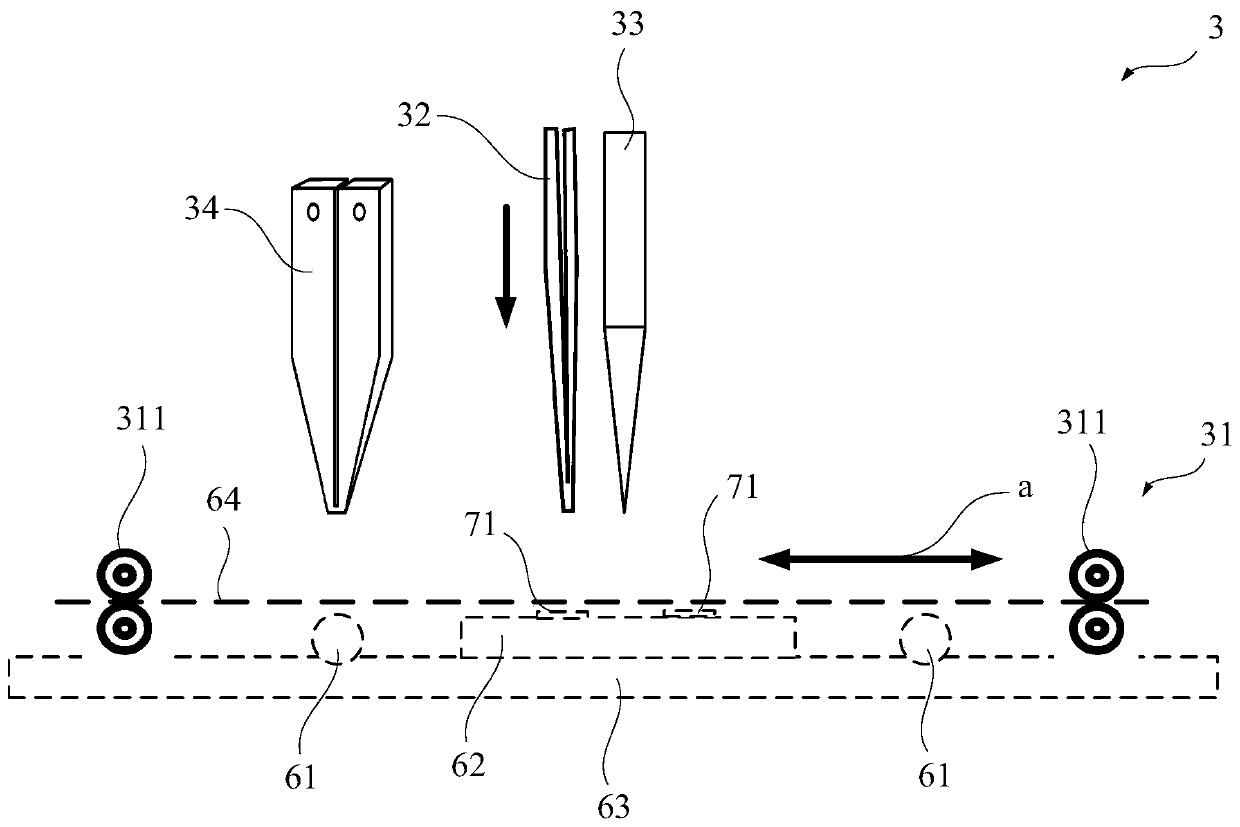

[0080] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a contactless card manufacturing equipment, which is used to manufacture contactless cards. The contactless card manufacturing equipment includes an antenna implantation device 1, a chip fixing device 2, a pin welding device 3 and a transmission device 4 . Among them, the antenna implantation device 1 is used to implant the copper wire 61 into the card making substrate 63, and the chip fixing device 2 is used to place the chip 62 in a corresponding fixed position on the card making substrate 63 to form a non- Contact the antenna of the card, and the pin welding device 3 is used to weld the wire 64 to the pin 621 of the chip 62 and the copper wire 61 to make the conduction between the chip 62 and the copper wire 61, and the transmission device 4 is used to connect the wire 62 to the copper wire 61. The card making base material 63 is transported between the antenna implanti...

Embodiment 2

[0111] Such as Figure 6 As shown, this embodiment also provides a contactless card manufacturing equipment, which has roughly the same structure as the contactless card manufacturing equipment provided in Embodiment 1, the difference is that in this embodiment, the contactless card manufacturing equipment The pin welding device 3 of the equipment includes two welding pins 32 arranged side by side, and the cutting mechanism 33 is located between the two welding pins 32 . This pin welding device 3 can be applied to the situation that the chip 62 has more than two pins 621, and the wire 64 can be welded on two pins 621 wherein, and these two pins 621 are drawn out through the wire 64 simultaneously. . Specifically, by setting two welding pins 32 on the pin welding device 3, these two welding pins 32 can simultaneously weld the wire 64 straightened and fixed by the fixing mechanism 31 on the two pins 621 of the chip 62. , and the cutting mechanism 33 is located between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com