Glass fiber slitting equipment capable of adjusting cutting width

A cutting width, adjustable technology, used in metal processing and other directions, can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

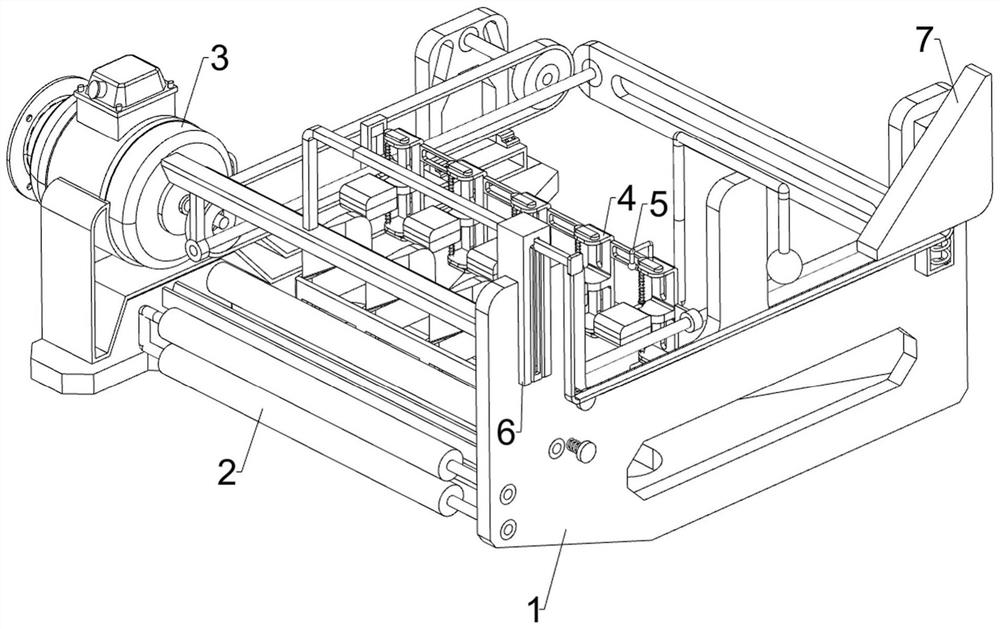

[0022] A glass fiber cutting equipment with adjustable cutting width, such as Figure 1-5 As shown, it includes a first fixed frame 1, a cutting assembly 2, a transmission assembly 3, and a clamping assembly 4. The first fixed frame 1 is provided with a cutting assembly 2, and the first fixed frame 1 is provided with a transmission device through rotation. The transmission assembly 3 is provided on the first fixed frame 1 with a clamping assembly 4 for clamping by sliding.

[0023] When using this device, the staff puts the glass fiber that needs to be cut into the cutting assembly 2, and after putting it in place, clamps the glass fiber through the clamping assembly 4, and after clamping, drives the clamping assembly through the transmission assembly 3 4 moves, and then drives the glass fiber to move, and the glass fiber is cut by the cutting assembly 2 while moving.

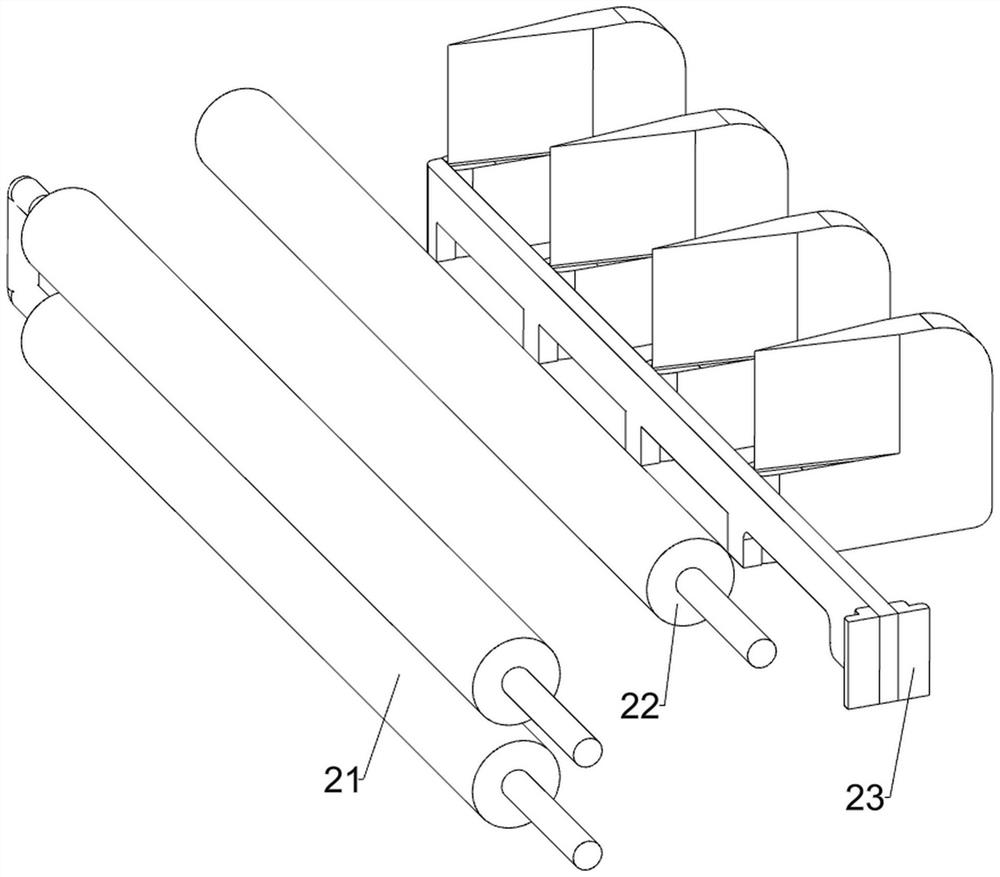

[0024] Such as figure 1 with figure 2 As shown, the cutting assembly 2 includes a first guide cylinder 2...

Embodiment 2

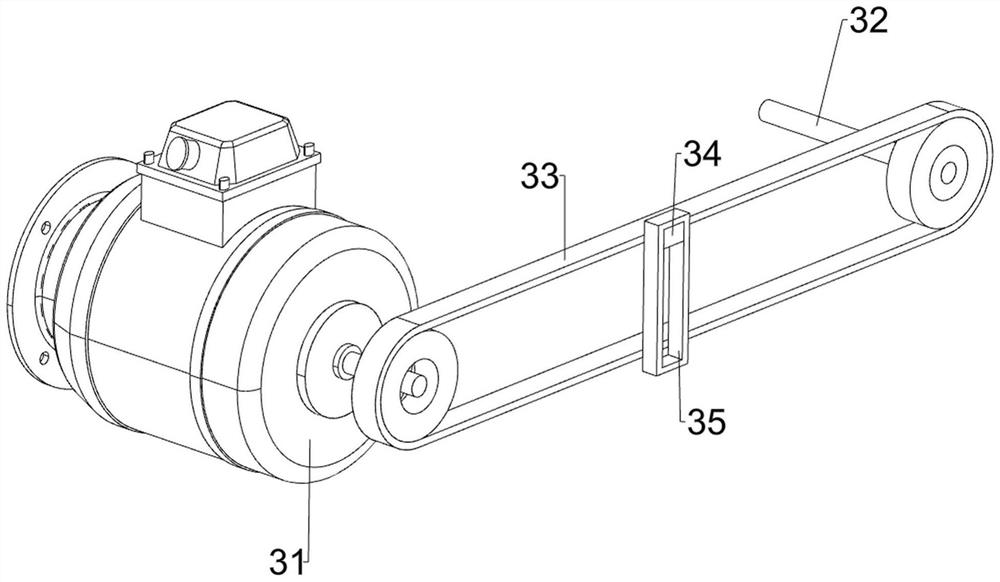

[0031] On the basis of Example 1, such as figure 1 with Figure 4 As shown, a pull assembly 5 is also included, and the pull assembly 5 includes a moving rod 51, a second spring 52, a push frame 53, a first wedge block 54 and a first contact rod 55, and the front part of the first fixed frame 1 is slidingly designed. There are two moving rods 51, a second spring 52 is wound between the moving rods 51 and the first fixed frame 1, a pushing frame 53 is arranged between the two moving rods 51, and the pull plates 45 cooperate with the pushing frame 53, The right part of the pushing frame 53 is provided with a first wedge-shaped block 54 , and the right part of the second fixed frame 42 is provided with a first contact rod 55 , and the first contact rod 55 cooperates with the first wedge-shaped block 54 .

[0032] When the glass fiber is cut, when the pulley set 33 rotates through the fixed block 34 to drive the moving frame 35 to move forward, the second fixed frame 42 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com