Water immersion type environment-friendly plastic particle cooling device

A technology of plastic granules and cooling devices, applied in the direction of coating, etc., can solve the problems of slow cooling efficiency of plastic granules, waste of resources, etc., and achieve the effects of improving cooling efficiency, facilitating cooling processing, and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

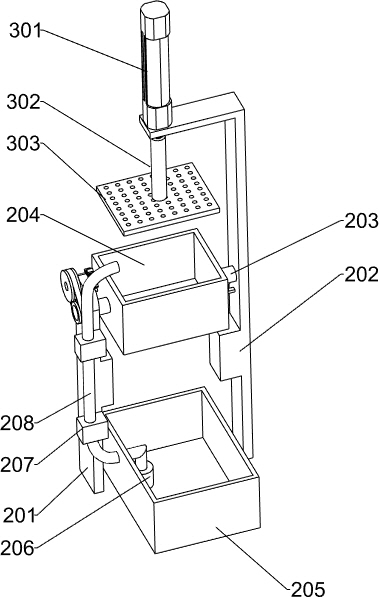

[0031] A water-immersed environment-friendly cooling device for plastic granules, such as figure 1 As shown, it includes a mounting frame 1, a cooling mechanism 2 and a pressing mechanism 3, the mounting frame 1 is provided with a cooling mechanism 2, the cooling mechanism 2 is provided with a pressing mechanism 3, and the pressing mechanism 3 cooperates with the cooling mechanism 2.

[0032] When the plastic particles need to be cooled, the user adds an appropriate amount of water into the cooling mechanism 2, and pours an appropriate amount of plastic particles into the cooling mechanism 2, and then the user makes the pressing mechanism 3 work, and the cooling mechanism 3 can be cooled. All the plastic particles in the mechanism 2 are immersed in water, so that the plastic particles can be cooled conveniently. After the cooling of the plastic particles is completed, the user resets and closes the pressing mechanism 3, and then the user collects the plastic particles in the co...

Embodiment 2

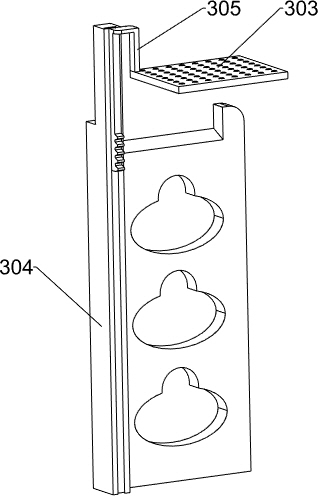

[0034] On the basis of Example 1, such as figure 2 As shown, the cooling mechanism 2 includes a first bracket 201, a second bracket 202, a first rotating shaft 203, a storage box 204, a water tank 205, a water pump 206, a fixed sleeve 207 and a water outlet pipe 208, and the first bracket 201 is fixed on the On the mounting bracket 1, the mounting bracket 1 on the rear side of the first bracket 201 is provided with a second bracket 202, and the upper parts of the first bracket 201 and the second bracket 202 are rotatably connected with a first rotating shaft 203, and the front and rear two first rotating shafts 203 is provided with holding box 204, and on the installation frame 1 between the first bracket 201 and the second bracket 202, a water tank 205 is placed, and a water pump 206 is arranged in the water tank 205, and the upper and lower sides of the first bracket 201 right side wall The sides are fixedly connected with fixed sleeves 207, and a water outlet pipe 208 is a...

Embodiment 3

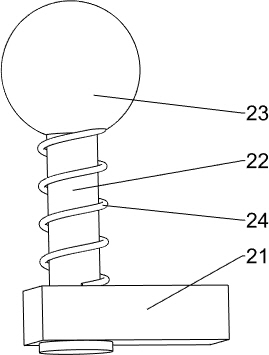

[0041] On the basis of Example 2, such as Figure 5 As shown, it also includes a lower material box 4, a holding bucket 5, a fixed frame 6, a first slide bar 7, a connecting plate 8, a first spring 9 and a baffle plate 10, and the upper part of the installation frame 1 is fixedly connected with the lower material box 4. The top of the feeding box 4 is provided with a holding bucket 5, and the holding bucket 5 on the right side of the feeding box 4 is connected with a fixing frame 6, and the front and rear sides of the fixing frame 6 are slidingly provided with a first sliding rod 7 A connecting plate 8 is fixedly connected between the lower ends of the front and rear two first sliding rods 7, and two first springs 9 are connected between the connecting plate 8 and the fixing frame 6, and the first springs 9 are respectively wound around the corresponding first sliding rods. On the bar 7, the bottom of the connecting plate 8 is equipped with a baffle plate 10, and the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com