Transportation equipment for rail transit

A technology for transportation equipment and rail transportation, applied in the field of transportation equipment for rail transportation, can solve problems such as low work efficiency, difficulty in loading and unloading goods, and difficulty for workers to move goods on shelves, so as to improve work efficiency and reduce fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

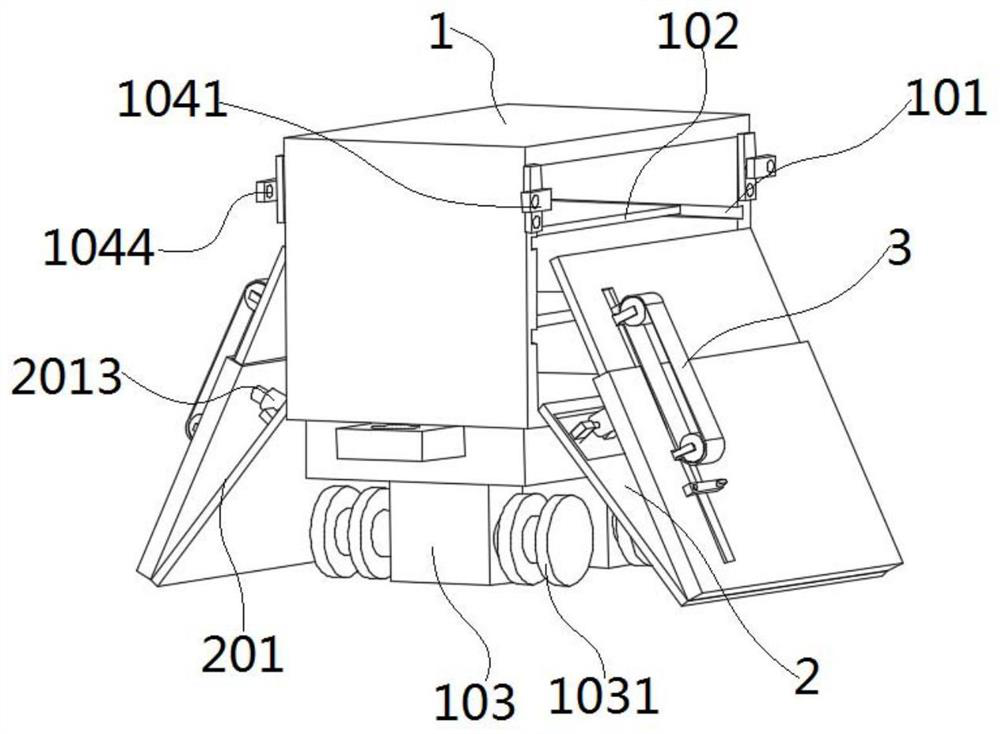

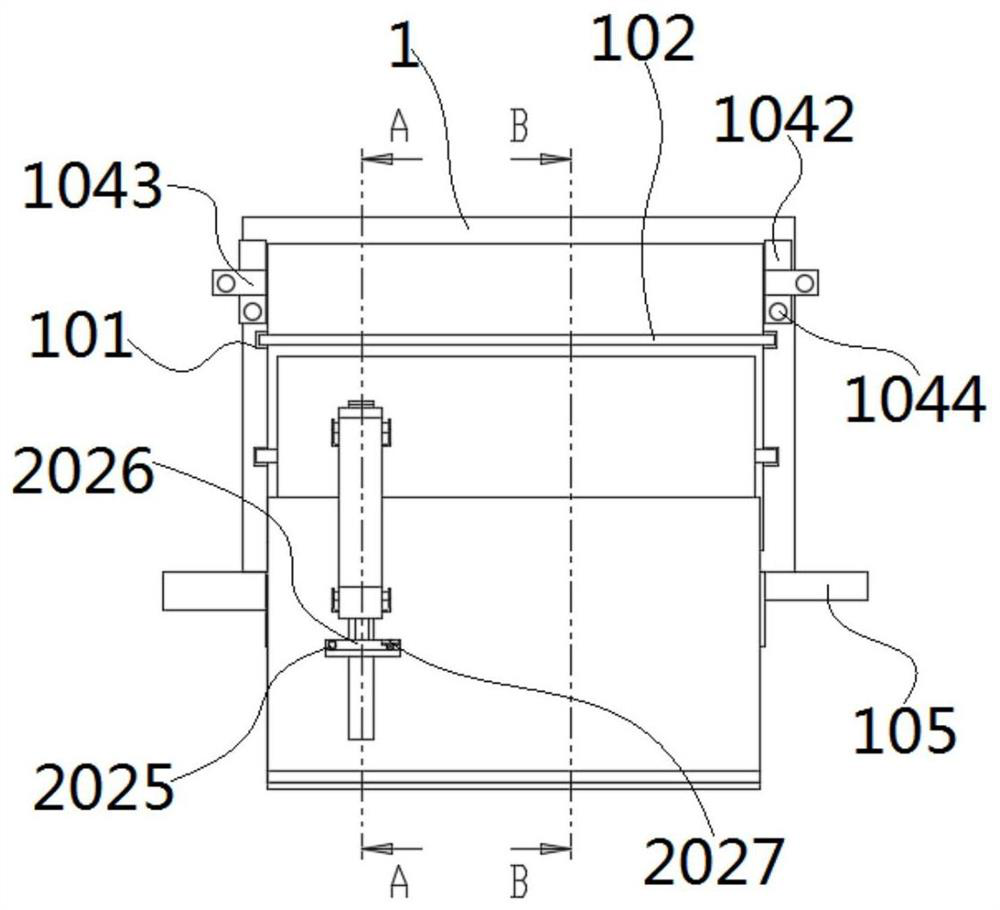

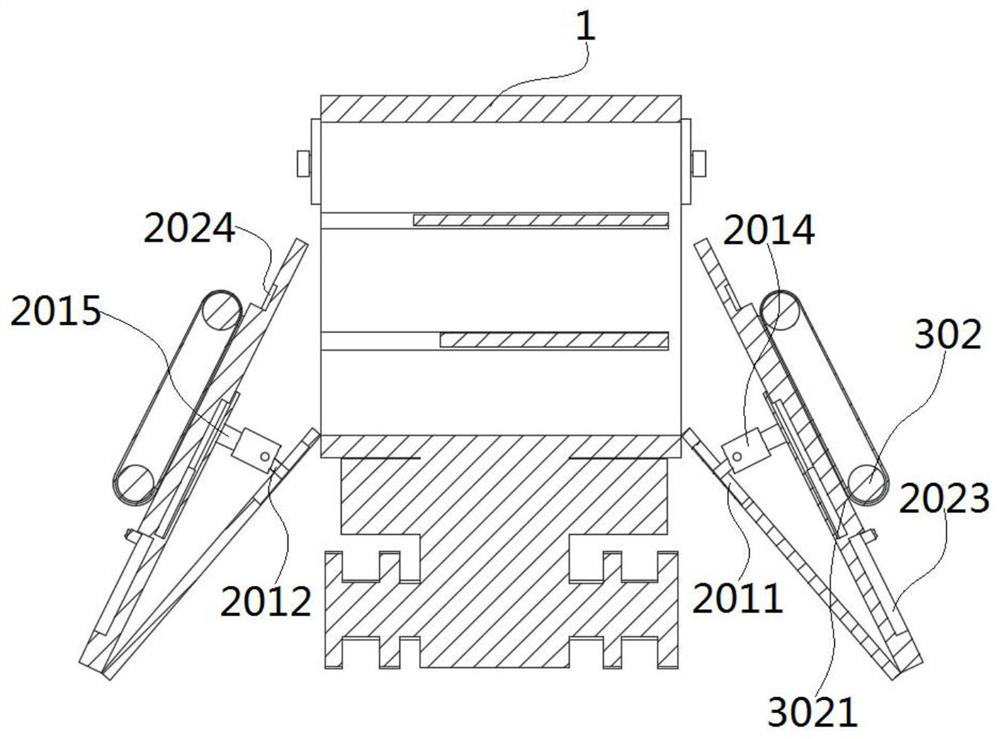

[0041] see Figure 1-6 As shown, the present embodiment is a kind of transportation equipment for rail transit. Its use method: when it is necessary to load the carriages of rail transportation, the lock plate 1042 is rotated to be perpendicular to the fixed lock plate 1043 and the door 2 is lowered. The amount of loaded goods adjusts the number of partitions 102, opens the conveyor belt 3, and the worker puts the goods on the conveyor belt 3, so that the goods are transmitted to the compartment 1 through the conveyor belt 3. The rod 2013 lifts the inner compartment door 202, then the second telescopic rod 2021 pushes the extension plate 2022 out, then slides the conveyor belt 3 upwards along the track groove 2023 into the second track groove 2024, then rotates the fixed plate 2026 and tightens the bolt 2027 to push the conveyor belt 3 is fixed, and the workers put the goods on the conveyor belt 3, and then transfer the goods to the partition 102 in the compartment 1, which av...

Embodiment 2

[0044] see Figure 1-6 As shown, this embodiment is a characteristic working principle of a rail transit transportation device: the telescopic rod 2013 is pressurized by the cylinder 2014 to push the telescopic column 2015 out, and drives the extension plate 2022 to stretch out to make it reach the required position, and the telescopic rod 2013 It has the same structure as the second telescopic rod 2021.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com